A ground rod clamp is a device used to securely and electrically connect the ground rod to the grounding conductor or grounding system. It ensures a reliable and low-resistance connection between the ground rod and the grounding system. Additionally, the ground clamps provide a mechanically sound and electrically conductive connection between the ground rod and the grounding system. This ensures that fault is efficiently directed into the ground and that the grounding system remains intact and functional.

Components of the ground rod clamp

The components of the ground rod clamps work together to provide a secure and low resistance connection between the ground rod and the grounding conductor. The components available on a ground rod clamp depends on factors such as the size of the ground rod, compatibility with the grounding conductor and the specific requirement of the applications. the following are the common components of a ground rod clamp.

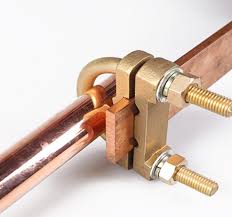

Clamp body – the main part of the ground rod clamp is a metal body that holds the ground rod in place.

Bolt/screws – the bolts and screws secure the clamp tightly around the ground rod. Therefore, they ensure a strong and reliable connection between the clamp and the rod.

Pressure plate – the pressure plate is inside the clamp body which creates a firm contact and improving the electrical conductivity.

Connection point – the ground rod clamps also includes a connection point or lug where the grounding conductor attaches. It is a threaded hole that allows the grounding conductor to be securely fastened.

Locking mechanism some of the ground rod clamps contain a locking mechanism to further secure the connection between the clamp and the ground rod. It prevents the clamp from loosening over time due to vibrations.

Types of ground rod clamps

Different types of ground rod conductors accommodate different ground sizes, conductors, and installation requirements. The best types of ground rod clamps should comply with the local electrical codes and standards. The following are the main types of ground rod clamps.

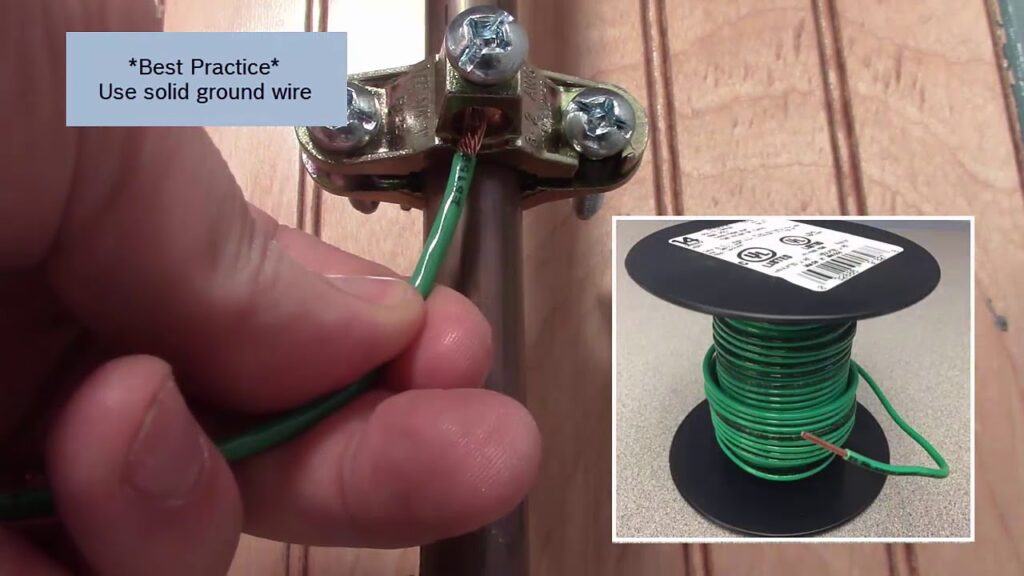

Screw-type clamp – This is the most basic type of ground rod clamps which features a screw or bolt that is tight to secure the clamp around the ground rod. It is easy to install and provides a reliable connection.

Compression-type clamp – The compression type clamp uses a compression mechanism such as a threaded rod or bolt to compress the clamp body against the ground rod. They also feature multiple pressure plates to ensure even pressure distribution.

Parallel clamp – Parallel clamps have two parallel plates that provide a larger surface area for contact with the ground rod. The plates connect by bolts or screws which compress against the rod to establish a solid connection.

Universal clamp – Universal clamps are adjustable clamps that can accommodate a range of ground rod sizes. They feature adjustable bots and screws that can move along a slot or groove in the clamp body. This allows for flexibility in securing different diameter ground rods.

Exothermic weld clamp – These clamps use a specialized welding process to create a permanent and high conductivity connection between the ground rod and the clamp. They form a molecular bond with the ground rod which offers excellent electrical conductivity and long-lasting performance.

Split-bolt clamps – Split bolt clamps have a split design with a threaded bolt and a nut installed by placing the clamp around the ground rod and tightening the bolt and nut to secure it. They are commonly used for smaller ground rods due to their versatility and ease of installation.

Direct-burial clamp – The clamps have a design for installing directly to the ground without the need for additional grounding electrodes. They are from materials that can withstand underground environments.

Applications of ground rod clamps

Ground rod clamps are important in various applications that require effective grounding and electrical safety. The electrical codes vary depending on the different industries and regions. The following are the main application areas of the ground rod clamps.

Power distribution systems – Ground rod clamps work in power distribution systems to establish a secure and low-resistance connection between the grounding conductor and the ground rod.

Telecommunication and data centers – Ground rod clamps provide proper grounding and minimize electromagnetic interference and radio frequency interference. Additionally, this ensures reliable grounding to maintain equipment performance and protect against electrical noise and disruptions.

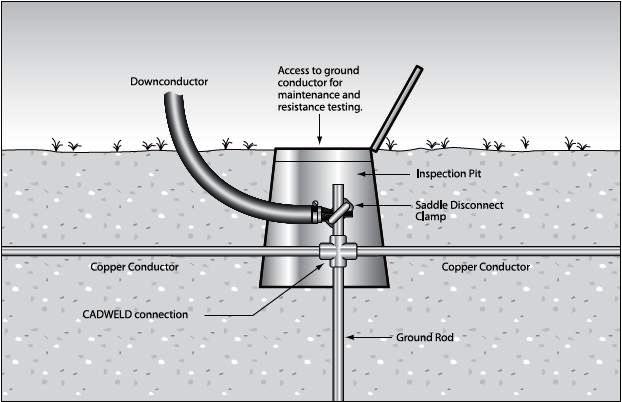

Lightning protection systems – The ground rod clamps connect the down conductor or lightning rod to the grounding electrode system. They also ensure a low-resistance path for lightning currents to dissipate safely int the ground. This also minimizes the risk of damage from lightning strikes.

Substations and power transformers – The clamps provide a secure connection between the grounding conductors and the ground rods. This helps divert the fault currents and ensure proper equipment protection and electrical system reliability.

Industrial machinery and equipment – Ground rod clamps work in particular machinery and equipment that require grounding for safety and reliable operations. Also, they help establish a solid connection between the equipment’s grounding conductor and the ground rod.

Oil and gas facilities – The clamps provide an effective grounding connection for equipment and structure to promote electrical safety, protect against electrical faults and comply with industry regulations and standards.

Renewable energy systems – The ground rod clamps establish proper grounding connections for inverters, power converters and support structures used in solar and wind farms. They also ensure electrical safety, protect against lightning strikes and comply with grounding requirements in these systems.

Installation process of the ground clamps

The installation process of the ground rod claps depends on the available electrical codes and standards of the local area. It is advisable to consult with a qualified electrician of grounding specialist for guidance and assistance during the installation process. The following are the basic procedures when installing ground rod clamps.

- Prepare the grounding system by selecting the appropriate ground rod, determining the location for installation and ensure that the ground conductor is ready for connection.

- Select a ground rod clamp that is compatible with the ground rod size and the grounding conductor. This involves factors such as material, size and type of clamp based on the requirements of your project.

- Position the ground rod clamp on the ground at the desired location and ensure that the clamp adapts correctly with the connection point aligned with the grounding conductor.

- Insert the grounding conductor into the connection point of the ground rod clamps which may involve threading the conductor through a hole, tightening a set screw or connecting it to a lug or terminal.

- Tighten the bolts or screws of the ground rod clamps using an appropriate tool like a wrench or screwdriver. Ensure that the clamp is securely fastened around the ground rod which provides a tight and reliable connection.

- Visually inspect the installation to ensure that the clamp is properly aligned and the grounding conductor is securely attached with no visible signs of damage or loose connections.

- Conduct a ground resistance test to measure the effectiveness of the grounding system using a ground resistance tester.

- Keep a record of the grounding rod clamp installation including the type of clamp, ground rod size, grounding conductor used and any test results.

Selecting the best ground rod clamps

The ground rod clamps selection process may be a tricky task as there are various types and designs of the clamps in the market. This is because they are from different manufacturers and suppliers in the industry. Also, it is advisable to consult with experts and professionals in the industry for guidance on the best rod clamp for your specific needs. The following are the key factors to consider when selecting ground rod clamps for your project.

- Ensure that the ground rod clap complies with the size and material of the ground rod you are using. The clamp should have a suitable diameter and design to securely fir around the specific ground rod size selected.

- Consider the size of the grounding conductor that needs to attach to the clamp. It should have a connection point or lug that can accommodate the size of the conductor.

- Choose a clamp made from corrosion resistant materials that are suitable for different environmental conditions for the installation.

- Consider the specific requirements of your application and choose a clamp type that best meets those requirements.

- Select high-quality ground rod clamps from a reputable manufacturer and look for clamps that meet the relevant industry standards. They should have undergone testing for reliability and durability to provide durability.

- Consider the potential for corrosion in the installation environment and choose a ground rod clamp that has appropriate corrosion resistance measures. This ensures longevity and reliable performance in corrosive conditions.

- Ensure that the ground rod clamps complies with relevant electrical codes and standards to ensure the clamp meets the necessary safety and performance requirements.

- Consult with a qualified electrician or grounding specialist which provides guidance based on their experience and knowledge of the specific application and electrical system requirements.

Frequently Asked Questions

What is a ground rod clamp as used on power and distribution systems?

A ground rod clamp is a device used to securely and electrically connect the round rod to the grounding conductor. It ensures a reliable and low-resistance connection between the grounding rod and the grounding system

What is the difference between the ground rod a ground rod clamp?

A ground rod is a long metal rod that injects directly into the ground to establish a direct electrical connection with the earth. It also provides a safe path for electrical currents to flow into the ground by dissipating the fault current, static electricity and lightning strikes. A ground rod clamp is a specific component used with a ground rod to securely fasten the grounding conductor. It also provides a reliable and low-resistance connection between the grounding conductor and the ground rod.

What are the benefits of ground rod clamps?

Secure connections

Low-resistance path

Enhanced electrical safety

Reliable grounding

Corrosion resistance

Versatility

Compliance with electrical codes

Easy installation process

What are the limitations of ground rod clamp?

Soil conditions limitations

Prone to corrosion

Mechanical stability

Size limitations

Overloading limitations

Installation limitations