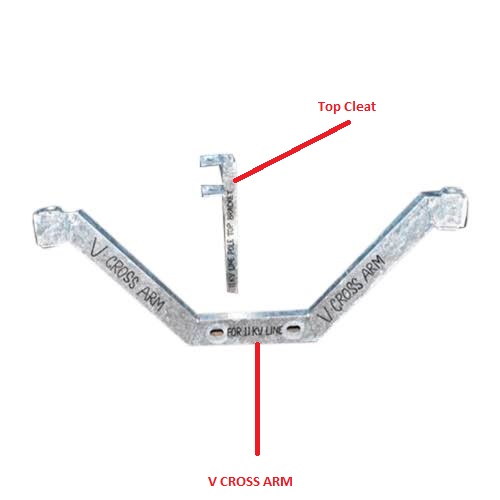

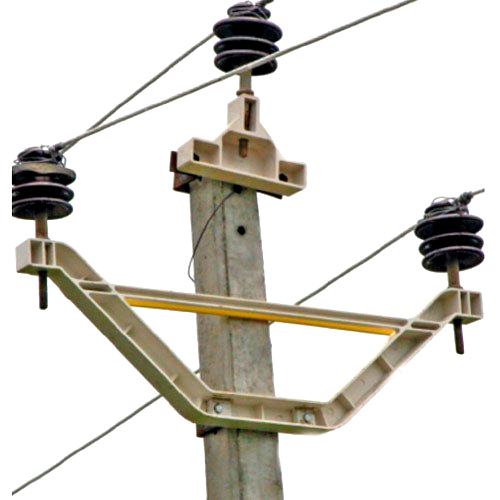

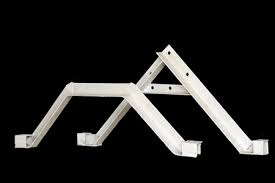

A V type crossarm is a structural component used to support and separate multiple conductors. It helps to ensure the safe and reliable transmission of electrical power. The components resemble the letter “V” hence the name. The crossarm helps to support multiple electrical conductors. This includes power lines, insulators or fiber-optic cables. It also allows the separation of conductors to help maintain proper spacing between them. This helps to reduce the risk of electrical arcing and interference. It may be from materials such as wood, steel and composite materials. The V type crossarm helps to meet the specific demands of power distribution for reliable support and conductor separation in the region in South America. Examples include heavy-duty type crossarm, offset v-type crossarm, composite, double and standards v-type crossarm. They find use in applications such as transmission lines, telecommunication, railway electrification and renewable energy projects.

Key features of V type crossarm

V type crossarms have several features that help them provide support and separation for conductors. They also help ensure safe and reliable transmission of electrical power. It does this while providing mechanical support and clearance. The features vary based on the application and project requirements. The following are the key features of the V type crossarm.

- Conductor spacing – the crossarms help to maintain consistent spacing between conductors. This helps to ensure electrical safety and preventing accidental contact between wires.

- Material – they are available in various materials including wood, steel and composite materials.

- Corrosion resistance – corrosion resistant coatings help prevents rust and degradation.

- Versatility – they are available in different sizes to hold various applications and conductor arrangement.

- Ease of installation – the crossarms have designs to allow easy installation on transmission poles, towers or other support structures. This allows for efficient and cost-effective deployment with reduced installation time.

- V-shape configuration – the V-shape design allows for the separation and support of multiple conductors. This helps to reduce the risk of electrical interference.

- Mounting points – the availability of attachment points help to ensure secure conductors, insulators and other hardware.

- Strength and durability – the crossarms are capable to withstand mechanical stresses and higher loads.

Selection and installation of V type crossarm

Proper selection of the V type crossarm ensures the safe and reliable operation of overhead transmission lines. It includes considering several factors that impact the decision-making process of the crossarm. These factors include material, environmental factors, load-bearing requirements, configuration and spacing. The installation should ensure safety and compliance with industry standards. The following is a step-by-step installation process of the V type crossarms.

- Preparation – gather all the necessary tools required for the installation. This includes V-type crossarm, insulators, conductor cables, fasteners and safety equipment.

- Site assessment – inspect the transmission poke to ensure it is in good condition. Check the pole or tower is properly anchored or grounded.

- Crossarm positioning – determine the height and position on the pole for the V-type crossarm. Consider conductor clearances, load distribution and project specifications.

- Crossarm attachment – secure the V-type crossarm to the pole at the marked points using appropriate fasteners.

- Insulator installation – attach the insulator on the crossarm to provide electrical insulation.

- Conductor installation – install the conductor cables on the insulators. This is to ensure the conductors are properly tensioned.

- Final inspection – inspect the installation to confirm it meets safety standards and regulatory requirements.

- Testing – perform the necessary tests for electrical conductivity and overall system performance.

- Documentation – keep detailed records of the installation including adjustments made and drawings.

Maintenance and inspection of V type crossarm

Regular maintenance and inspection of the crossarm to ensure the safety, reliability and longevity of the system. Proper maintenance and inspection help to identify and address potential issues. The frequency of the maintenance and inspection depends on the environmental conditions. The following is a basic guide to maintenance and inspection of the V type crossarm.

- Establish regular inspections of V-type crossarms at regular intervals. This varies depending on environmental conditions.

- Perform a detailed examination of the entire crossarm. This is including points, insulators, conductor alignment and signs of wear.

- Perform tests to assess the integrity of the crossarm structure to detect hidden defects.

- Inspect for signs of corrosion, rust or degradation and apply treatments as needed.

- Perform visual inspections of the V-type crossarms to check for signs of damage, wear or corrosion. Check for cracks, splits, loose hardware or any visible defects.

- Clean the crossarms and ensure they are free from debris, vegetation or contaminants. This helps to prevent accumulation of moisture which leads to corrosion.

- Check and tighten bolts, nuts and other fasteners to ensure they are secure.

- Repair or replace damaged or deteriorated crossarms, insulators or conductors.

- Maintain detailed records of inspection results including any findings, corrective actions and recommendations.

Comparative analysis of V type crossarms in South America

A comparative analysis includes assessing and evaluating different designs, materials and features. It includes several other factors like load-bearing requirements, environmental conditions and maintenance considerations. Additionally, it is advisable to consult with professionals for guidance on the analysis in South America. The following are the factors to include in the comparative analysis for the crossarm.

- Material – there are various materials used in the construction of the V type crossarms. These materials include wood, steel or composite materials. Assess the benefits of each of the materials and their suitability in various applications.

- Environmental conditions – South America has diverse weather and environmental conditions. Ensure to select the V type crossarm can resist the diverse weather conditions in South America.

- Conductor clearance – ensure the crossarm provides adequate conductor clearances to prevent electrical interference.

- Safety and regulatory compliance – ensure the crossarm adheres to safety and regulatory standards. This is to ensure the safety of the overhead transmission lines.

- Suitability – the suitability of a particular crossarm type depends on the applications load.

- Load-bearing capacity – the crossarms should withstand the wind loads and mechanical loads.

- Maintenance requirements – assess the maintenance requirements of each crossarms. This helps to prevent corrosion and durability.

- Cost – assess the cost of each V type crossarm depending on each of the materials used in the manufacture.

Certifications and standards in South America

There are various standards and certifications that govern the use of V type crossarms in South America. They help to ensure the safety, reliability and compliance with industry requirements. These standards vary depending on each country. Additionally, it is advisable to work with reputable manufacturers and suppliers. This is to help ensure the crossarms meet the industry expectations. The following are the certifications and standards in South America.

- IEEE standards – these standards help establish standards related to design, testing and performance of electrical equipment.

- ASTM standards – these are international standards for a wide range of materials and products.

- NEMA – this offers standards and guidelines for electrical equipment and systems.

- ANSI standards – these standards help in developing and maintaining standards.

- National electrical codes – different countries have their own electrical codes and regulations.

- ISO certification – this help to demonstrate their commitment to quality management systems.

- Local regulations – the V type crossarms must adhere to local electrical and safety regulations in each country.

- Industry associations – industry specific associations offer guidelines and best practices for the use of crossarms.

Regional market for V type crossarms in South America

The regional market depends on various factors that influence the demand and availability of crossarms. This includes economic conditions, infrastructure development and energy sector growth. The regional market is also dependent on availability of manufacturers and suppliers in the region. Also, manufacturers and suppliers should pay attention to these market trends to ensure their continued success in the market. The following are the factors that influence the regional market for v type crossarms in South America.

- Technological advancements – there are various advancements in crossarm materials and designs. These include composite materials and corrosion-resistant coatings.

- Competition – presence of manufacturers and suppliers of V type crossarms influence price, quality and materials.

- Environmental conditions – there is a wide range of environmental conditions in South America. These conditions influence the choice of crossarm materials and designs.

- Energy sector growth – the growth of the energy sector influences the demand for V type crossarms.

- Aging infrastructure upgrade – replacement of older crossarms with newer crossarms require the use of durable crossarms.

- Economic conditions – the economic stability and growth of individual countries impacts the pace and scale of infrastructure development.

Frequently asked questions

What is a V type crossarm and its role in overhead transmission lines?

A V type crossarm is a component used to support and separate multiple conductors in overhead transmission lines. It helps to maintain proper conductor spacing and clearance on the transmission lines.

What are the considerations when selecting V type crossarms for a project in south America?

There are various factors to consider when selecting the crossarms for a project in south America. These factors include material, load bearing capacity, environmental factors, maintenance requirements and compliance with local standards.

What is the maintenance and inspection of V type crossarm in South America?

The frequency of the inspections varies depending on factors like environmental conditions and regulatory requirements. it can be monthly, semi-annually, or annually.