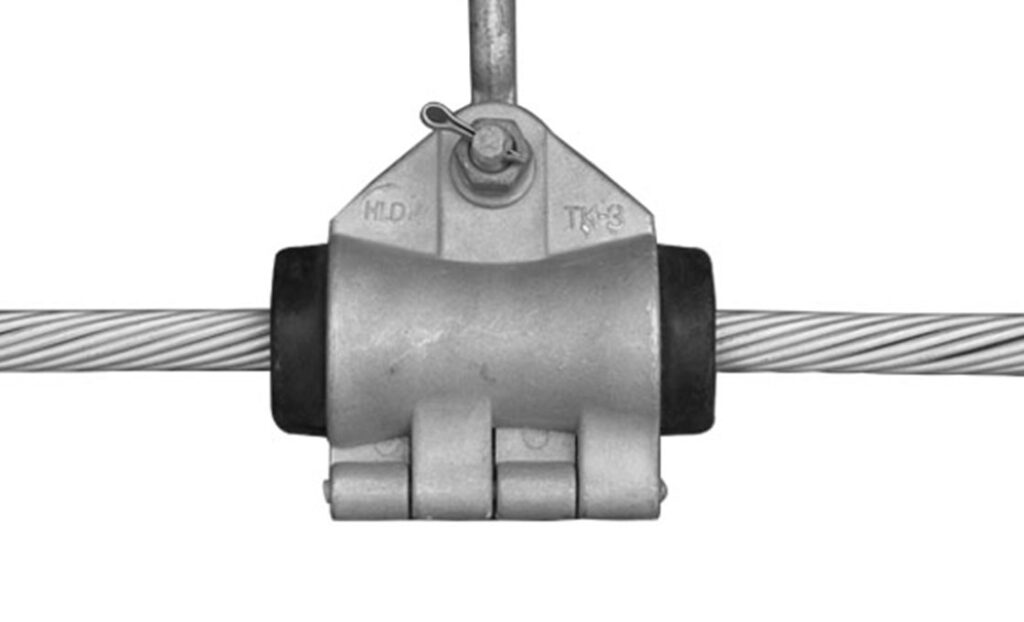

A suspension clamp is a device used to support the conductors at a suspended position. They install at regular intervals along the power line to ensure the conductors are in a secure position. This also helps to provide proper tension and prevent sagging on the overhead lines. They are from durable materials such as galvanized steel or aluminum alloy. These materials provide strength and corrosion resistance. The main purpose of the suspension clamp is to stand the weight of the conductors and maintain their position. Suspension clamps consists of other components and features which help the connection to the power line system. They include guy wires, insulators and spacers which help maintain the separation between the conductors.

Components of suspension clamp

Suspension clamps play a vital role in the construction and maintenance of overhead power lines. The available components of the clamps provide mechanical support and stability to the conductors. Suspension clamps have key components working together to secure and support the conductors on overhead power lines. The components, however, vary depending on the manufacturer, size and type of conductor and specific application. The following are the main components of the suspension clamp.

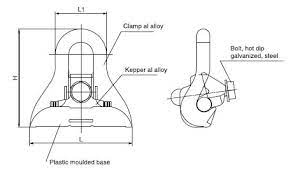

- Clamp body – this is the main part of the clamp which is a rigid structure made of materials resistant to rust and corrosion. The body works by enclosing to hold the conductor in place.

- Conductor grips – the available jaws inside the clamp body hold the conductor and prevent it from slipping off.

- Fasteners – fasteners such as bolts, nuts, washers, clevis and screws help to attach the clamp to maintain proper tension.

- Straps – the straps are from metal pieces that help to connect the body of the clamp to the supporting structure.

Types of suspension clamps in power line systems

Each type of suspension clamp for overhead power lines, has a unique design tailored to meet specific applications and conductor configurations. They ensure the conductors are properly secured and prevent any loose connections. Therefore, it is advisable to consult with industry experts for guidance on the best clamp for your specific needs. The following are the common types of suspension clamps.

Bolted suspension clamp – this clamp utilizes bolts and nuts to secure the conductor within the clamp body. It has a split body that bolts together around the conductor.

Wedge-type suspension clamp – this clamp uses a wedge-shaped component to secure the conductor and secure the grip.

Vibration dampening suspension clamps – this is a type of suspension clamp with extra dampening mechanisms. The mechanism help to reduce vibration in the conductors. This helps reduce the risk of fatigue and potential damage to the power line.

Clevis suspension clamp – this clamp has a clevis pin that holds the conductor in place. This pin prevents it from coming loose.

Preformed suspension clamp – this clamp has a design tailored for use with preformed power line conductors.

Fiber optic suspension clamp – fiber optic suspension clamps provide a secure and separate support system for the fiber optic cables.

Applications of suspension clamps

Suspension clamps help to support and maintain the integrity of overhead power line systems. They also ensure reliable and efficient transmission of electrical power. Hence, they find various uses in different applications in the fields. The following are the main applications of suspension clamps.

- Overhead power lines – suspension clamps help in conductor support, tension maintenance and mechanical support of the power lines. tis helps to maintain the reliability and integrity of the overhead power lines.

- Telecommunications lines – the suspension clamps provide mechanical strength, line configuration and protect fiber optic cable on telecommunication lines. this helps to ensure there is efficient data transfer from one point to another.

- Industrial applications – suspension clamps incorporate the use of insulating components. They help provide electrical isolation between the conductors and the supporting structure. This helps prevent electrical leakage and ensure safety and reliability of the power line.

- Vibration dampening – strong winds and other external factors may cause swinging. The swinging leads to vibrations in the overhead power lines. The suspension clamps help mitigate the effects of conductor fatigue and stress.

Installation process of suspension clamp in power line systems

Installation process of suspension clamps vary depending on the specific design of the clamp and regional guidelines. Some manufacturers and suppliers offer instructions on the installation for their specific product. Additionally, it is advisable to consult with professionals in the industry for guidance on the installation if in doubt. This helps ensure the safety and security of the installations. The following is a basic process of suspension clamp installation.

- Prepare the tools, equipment and materials to use prior to installation. The tools include suspension clamps, fastening devices and insulating components.

- Check the components for any damage, corrosion or defects. This ensures all parts are in good condition for installation.

- Find the suitable locations for installation along the power line. The location bases on line configuration, conductor spacing and engineering specifications.

- Ensure the mounting structures are ready and capable of supporting the suspension clamps and check for integrity and stability.

- Insert the conductor into the opening of the suspension clamp and ensure the conductor is properly positioned and centered within the clamp body.

- Close the suspension clamp around the conductor securely and tighten the bolts to firmly hold he conductor in place.

- Attach the suspension clamp to the designated mounting structure which involves using bolts, and other fasteners. This ensures the attachment is secure and provides adequate support for the conductor.

- Ensure the insulating materials if applicable are properly positioned and provide efficient electrical insulation between conductor and structure

- Inspect the installation to ensure proper positioning and alignment to verify the conductors are securely held in place.

Selecting the best suspension clamp for power lines

Suspension clamps should ensure reliable and safe operations for your overhead power lines. Hence, it is crucial to select the best suspension clamp that meets the specific requirements of your installation. Additionally, it is advisable to consult with industry professionals for detailed specifications and recommendations. There are a number of factors to consider when selecting the clamps which are as discussed below.

- Consider the cost effectiveness of the suspension clamp by comparing process from different manufacturers. Keep in mind the quality, performance and durability of the clamp.

- Evaluate the ease of installation and maintenance requirements of the suspension clamp and choose clamps that require minimal maintenance and repair.

- Consider suspension clamps that feature vibration dampening mechanisms to help reduce fatigue and stress on the conductors.

- Assess the material composition of the suspension clamps which should be from durable materials.

- Check the load capacity of the suspension clamp to ensure they can support the weight of the conductors and additional loads.

- Determine the size and configuration of the conductors used in the power line to ensure proper fit and secure grip.

- Ensure the selected clamp complies with relevant industry standards and regulations. They include standards for mechanical strength and electrical insulation.

- Consider the reputation and track record of the suspension clamp manufacturer for quality products and technical support.

Frequently Asked Questions

What is a suspension clamp as used in power line systems?

A suspension clamp is a device used on power line system to support and secure the conductors. They help prevent the conductors from coming loose in events like storms or other disturbances.

What are the main application areas of suspension clamps?

Power transmission lines

Cable television lines

Telecommunication lines

Industrial applications

Vibration dampening

What are the advantages of using suspension clamps?

Secure conductor support

Improved electrical performance

Easy installation and maintenance

Mechanical stability

Safety enhancement

Durability

What are the disadvantages of suspension clamps?

Load capacity limitations

Limited adjustability

Regular maintenance and inspection

Installation skills

Conductor compatibility