An armor rod is a component that improves the conductor’s durability and mechanical strength. Its primary purpose is to shield the conductor from wear, abrasion, and vibration brought on by ice, wind, and other environmental factors. Armor rods are compatible with various parts and add-ons that support the durability and dependability of overhead lines. Armor rods come in a variety of materials, including galvanized steel and aluminum. These materials give conductors in high-risk locations extra help. Preformed armor rods, suspension rods, helical armor rods, and spacer dampers are examples of common types of armor rods. They work in many different purposes, including electrical insulation, telecommunication, power lines and construction.

Common elements of armor rod

There are various elements that make up the armor rod. These elements help the rods to provide reliability and efficiency in transmission lines. they also make the armor rods a popular choice in the industry. The following are the common elements of the armor rod.

- Backbone – the core of the armor rod provides the primary stiffness and strength. Composite materials, galvanized steel, and aluminum alloy make up the core of the rod.

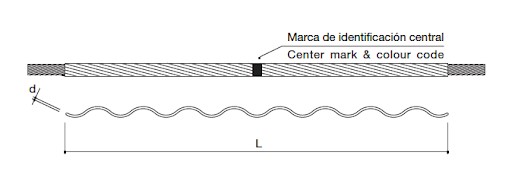

- Helical wires – during manufacture the rods are pre-formed into the helical shape. The shape aids in encircling the conductors to add stability and strength. The armor rod’s thickness varies based on its size and intended application.

- Coating – a few of the rods have an external coating that provides further defense against particular environmental elements. Common materials for coatings are polyethylene, epoxy, and PVC. Both UV protection and electrical insulation are from these materials. Additionally, they strengthen chemical and abrasion resistance.

- Characteristics for easy installation – a few of the rods contain extra characteristics that make installation easier and more secure. Crimping sleeves and end loops are two examples of these features.

Installation guidance for armor rod

The installation process is the crucial part of using armor rods which ensure the safety use of the conductors. It thus requires careful planning and use of the right tools for installation. Additionally, it is advisable to seek guidance from professionals whenever in doubt of the process. The following is a basic installation process for armor rod.

- Make that the installation crew has all the required safety gear and that all safety precautions are in place.

- Depending on the unique needs of the transmission line, choose the appropriate types of armor rods for installation.

- Determine the conductor’s intended locations for the armor rod installation. Suspension points and dead ends are typical locations.

- To avoid any pollutants, dust, or dirt affecting the installation procedure, clean the conductor using the right techniques.

- Lubricate the conductor to ease the ease of installation. By doing this, the conductor and the armor rods have less friction.

- Align the armor rods by positioning them on the conductor. As specified, wrap the conductor with the armor rods.

- After the armor rods install, use the clamps to keep them snug on the conductors.

Guidelines on inspection of armor rods

Regular inspection of the armor rods helps to ensure proper functioning and performance in the long run. It also helps to identify the components that need replacement or repair. Inspection helps to identify the potential problems that may lead to failures and accidents. Additionally, it is advisable to perform periodic inspection to ensure optimal performance. The following is an inspection guide for armor rods.

- Examine each armor rod for indications of physical harm, such as bends, dents, or corrosion. Make sure the armor rods positions and spaced apart.

- Look for any indications of corrosion on the armor rods. This is particularly true in areas where corrosion is from the environmental conditions.

- Look for any bolts, clamps, or other securing mechanisms that are loose. When installing, make sure to use the right torque values.

- Look for evidence of wear, abrasion, or damage on the conductor underneath the armor rods.

- Take into account the surrounding elements, including the climate, temperature swings and UV radiation. Verify if your armor rods are appropriate for the particular weather.

- Look for any indications of excessive vibration in the conductor and armor rods. This can cause fatigue and impair the armor rods’ functionality.

- Keep a record of the inspection’s specifics and findings, including with the kinds of armor rods used and their anticipated lifetime.

Proper maintenance of armor rods

Proper maintenance of the armor rods helps to ensure the safety and longevity of the transmission lines. It also helps to identify and address potential issues that may lead to accidents and blackouts. Also, it is advisable to conduct maintenance to ensure the continued reliability and performance of the transmission lines. The following is a general guideline for proper maintenance for armor rods.

- Visual examination on a frequent basis – check armor rods on a regular basis. Look for indications of corrosion, physical damage and any misalignment.

- Tightness – verify the tightness of clamps, fasteners and other securing systems during fastening. To make sure the fasteners are within the recommended torque value, use wrenches.

- Spacer damper maintenance – check for wear or damage on the armor rods and spacer dampers by inspecting and maintaining them.

- Monitoring – to keep track of and document the amounts of conductor vibration, use line monitoring equipment. Potential damage to the armor rod is mainly indicated by vibration.

- Environmental aspects – examine how the environment affects the performance of armor rods. When there are alterations in the environment, take extra precautions.

- Replacement – swap out any worn-out or damaged armor rods, clamps or fasteners.

- Corrosion check – prevent corrosion by coating or compounding armor rods with materials resistant to corrosion.

- Cleaning – get rid of pollutants, dirt, or debris by clean the conductors and rods. Make sure the cleaning procedure does not harm the rods in any way.

- Examination – check the state of the conductor underneath the armor rods by conducting a conductor examination. Examine for wear, abrasions, and any problems that need a fix.

- Safety procedures – ensure that the maintenance staff has adequate training on appropriate inspection and maintenance processes.

- Thermal imaging – to find any unusual heat patterns along the conductor, use thermal imaging technology.

- Documentation – maintain records of maintenance activities, together with dates, conclusions, and actions performed. The records help to ensure the proper future decision making processes.

What is the need for using armor rods on transmission lines?

Armor rods provide various benefits and are crucial for use on transmission lines due to various reasons. They ensure the safety, reliability and longevity of the dynamic infrastructure elements. The armor rods also contribute to reliability, efficiency and safety of power grids. Also, it is important to understand the various problems that armor rods fix on overhead transmission lines. The following is the importance of armor rods.

- Damage avoidance – the rods serve as a barrier keeping out different dangers. This covers risks such as flashover, bending, compression and abrasion. If left untreated, these circumstances may degrade the conductor and increase the risk of failures and power outages.

- Strengthening conductor – they also provide support in that contribute to strength. This enables it to endure the larger weights as well as adverse weather conditions. Additionally, strengthening the lines’ resistance and lowering the chance of failures and interruptions is the usage of armor rods.

- Damage mitigation – no matter how small the damage, using armor rods keeps conductors safe. This keeps the damaged areas from getting worse and helps to stabilize them.

- Decreased outages – this contributes to a steady and dependable supply of electricity. The well-being and productivity of the economy are also affected by this.

- Longer longevity – they also increase the conductor’s lifespan. This lessens the need for expensive maintenance and replacements. It also increases productivity and reduces operating expenses.

- Decreased vibration – the rods absorb wind-induced vibrations that might cause conductor fatigue and breakage. A more dependable and steady power transmission system results from this.

- Potential for restoration – by using armor rods, the damaged conductors improve their operations. This lowers the expense of a full replacement.

- Increased safety – by preventing conductor failures, the rods lower the possibility of mishaps and injury. This also helps to ensure the longer serviceable life of the armor rods in various applications in the industry.

Frequently asked questions

Armor rods play a crucial role in preventing conductor damage, reduce downtime and cut the need for extensive repairs. This leads to reliability and efficiency of the transmission system.

The rods can install in existing transmission lines during routine maintenance or upgrades. It is advisable to follow proper installation techniques to ensue their effectiveness.

Signs like physical damage, corrosion, loose fittings or deviations from proper alignment during inspections show the need for maintenance.

There are various types such as helical armor rods, suspension armor rods and preformed armor rods. They help in specific applications with different requirements.