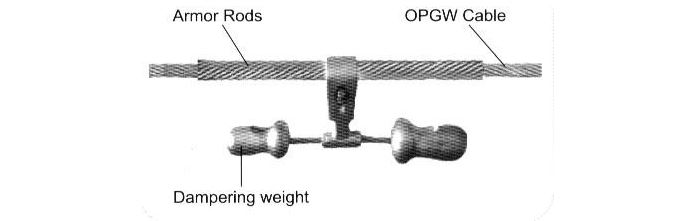

Armor rod is a piece of hardware used to protect cables from various types of damages in electrical industries. It provides mechanical protection and support for cables on overhead transmission lines. They are also known as spiral or helical rods. Armor rod is from high strength materials like aluminum alloys. Its design forms a spiral shape for easy installation. The armor rods should be compatible with the cable type, diameter and environmental conditions. They work in mechanical protection, load distribution, anti-vibration and for extra grip. Armor rods protect the cable against bending, compression and flash-over. They also repair damaged aluminum-based conductors and restore the conductor’s mechanical strength. They find use in various application such as power lines, telecommunications, construction and industrial applications.

Types of armor rod

Armor rods are of two types which offer similar benefits. These includes cable protection, load distribution and anti-vibration properties. These types include the helical and preformed armor rods. The armor rods categorize by function, material and installation method. Choosing between the types of armor rods depends on factors like the cable type, diameter, mechanical requirements and project specifications. Below are the types of the armor rods.

- Helical armor rods – these armor rods are also known as spiral armor rods which are the most used type. They provide mechanical protection and support to the cable while distributing mechanical loads along its length.

- Preformed armor rods – the rods are pre-formed into a particular design to provide enhanced grip and support to the cable. They are mostly used in applications where higher mechanical strength and gripping capacity is necessary.

- Aluminum armor rods – these rods provide protection against abrasion and vibration. They also offer corrosion resistance and suitability to various weather conditions.

- Alloy armor rods – these offer strength and protection especially in challenging environments.

- Corrugated armor rods – these rods have corrugated surfaces which increases their surface area. This helps to ensure protection against abrasion.

- Aluminum-clad steel armor rods – these rods combine the strength of steel with the corrosion resistance of aluminum. This helps to increase durability and tensile strength of the armor rods.

Materials and properties for armor rod

Armor rods are from several materials that offer specific advantages and disadvantages. There are various factors and properties that may influence the choice of armor rod materials. Proper selection of armor rod material helps to ensure best protection for your cables in the various applications. The materials selected depend on environmental conditions, cable type and diameter, costs and application requirements. The following are the common materials for armor rods.

- Aluminum alloy – this is the most common material for the armor rod and is also affordable. It is lightweight, good electrical conductor and provides moderate corrosion resistance. Aluminum alloy rods are cost effective, easy to install and adaptable to different cable shapes. Their main limitation is that they are susceptible to corrosion in harsh environments.

- Stainless steel – this material offers superior corrosion resistance compared to aluminum. Stainless steel rods are durable, temperature resistant and offer high strength. Their limitation is that they cost higher than aluminum, are heavy weight and less flexible. They find use in application such as marine environments, chemical plants and offshore platforms.

- Galvanized steel – coated steel provides enhanced corrosion resistance. Galvanized rods balance between cost and performance, offer strength and are resistant to corrosion. They are more affordable than stainless steel and heavier than aluminum. Their limitation is that they can be heavier than desired and the coating may chip.

- Fiberglass – these materials work best for cables exposed to extreme heat.

- Waterproofing coatings – these coatings especially help in underground applications exposed to moisture. It resists rust and corrosion for longer serviceable life.

- Abrasion-resistant materials – this may include rough or textured surfaces for high friction environments.

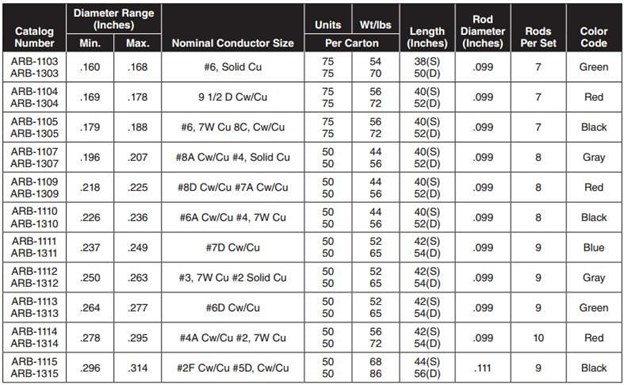

Technical specifications for armor rods

The specifications for armor rods vary depending on various factors like material, size, application and manufacturer. The specific technical specifications may also vary depending on your needs. Additionally, it is advisable to consult the manufacturers technical data sheet. The following are general specifications for armor rods.

- Material – the specific materials depend on application needs. Common specifications for materials include aluminum alloy AA8000 series, stainless steel AISI 304, galvanized steel ASTM A641 Grade.

- Size – the diameter of armor rod fits different cables ranging from 6mm to 25mm. The length is pre-cut for specific applications.

- Strength – the strength of the armor rod depends on material and diameter ranges from 400MPa to 1200MPa. The compression strength depends on material and diameter.

- Fatigue resistance – the ability to withstand bending without degradation expresses some cycles to failure at specific stress level.

- Surface finish – this may include textured or smooth depending on application requirements. The rods may also have extra coatings for corrosion protection.

Technical specifications

- Diameter Range: .244 – .259 (inches)

- Nominal Conductor Size: #4, 6/1, 7/1 #4, 7W, Alum. Alloy

- Length: 40 inches

- Rod Diameter: 0.146 inches

- Color Code: Orange

Industry advancements and updates for armor rods

The industry for armor rods experiences several advancements and updates that improve their performance, versatility and ease of use. These include technologies in new materials, features and functionalities. They help to improve their effectiveness and environmental sustainability. The advancements also contribute to enhanced cable protection and reliability. The following are the various innovations in the armor rod industry.

- Emerging trends – this includes technologies such as anti-tamper features, integration with AI and IoT and new cable technologies. These technologies help to increase protection and reliability of the armor rods.

- Digital design and selection tools – there are various online platforms and software emerging to help engineers and technicians. They help to select the ideal armor rod type and size for specific projects and improve performance.

- Optimized installation methods – there are a number of innovative tools and techniques developed to streamline armor rod installation.

- Customized designs – this includes 3D printing technologies that create custom armor rods with specific shapes and textures.

- Smart crimping systems – this features automated tension control and data recording to ensure proper installation and performance.

- Material innovations – this includes development of materials such as composite materials, self-healing properties and biodegradable materials.

- Robotic installation – there may be adoption of installation robots in the future. The robots may adopt use of advanced tools for fast, efficient and precise armor rod installation.

Supplier and vendor information for armor rods

Finding the right supplier may be a different kind of process for securing armor rods. Having a better understanding of your requirements help to find the qualified suppliers and manufacturer in the market. There are various factors that help to ensure the right selection of suppliers and manufacturers for your needs. They include:

- Quantity – analyze whether you need armor rods in small quantity or regular supply. This will help to select the vendors that are best suited for your needs.

- Material and size – identify the material and diameter best suited for your application needs. This will help to find vendors with the right inventory.

- Budget – consider your budget which will help refine the search to suppliers and vendors offering prices within your range.

- Location – location helps to narrow down the available suppliers near you for on-time delivery.

TTF Power Systems – they offer a wide range of armor rods in various materials, sizes, and features. They have a broad product range, competitive pricing and international reach. Their armor rods range from different materials, sizes, types and special features. TTF Power Systems have extensive experience in the power line hardware industry which ensures quality and reliability. The following is their contact information.

Website: https://ttfpower.com/

Catalog: https://ttfpower.com/about-us/

Landline (M-F, 9 am-6 pm): (+86) 22-8523-3528

Customer Service: [email protected]

Frequently asked questions

Armor rods help to protect overhead cables from physical damage caused by bending stress, abrasion, vibration fatigue and corrosion.

The selection process is a crucial aspect as it involves considering several factors. These include cable type and diameter, environment, cost and budget, application requirements and installation methods.

There are trends that offer a hope for use of armor rods in the industry. These include composite materials, integrated sensors, customizable designs, recycling and digital selection tools.

Armor rods are from various materials that offer durability, resistance to corrosion and high strength. These materials include aluminum, stainless steel and galvanized steel.