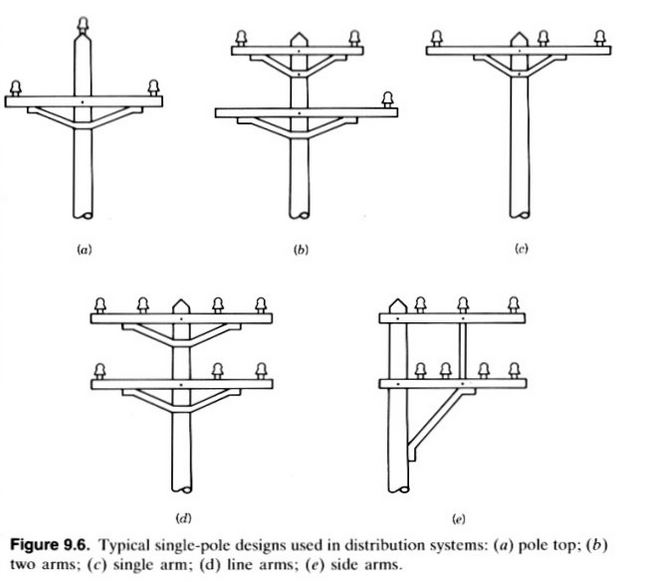

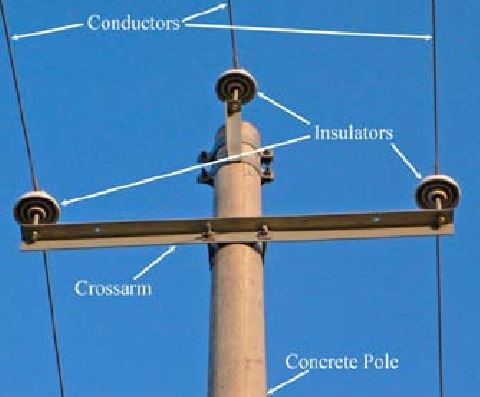

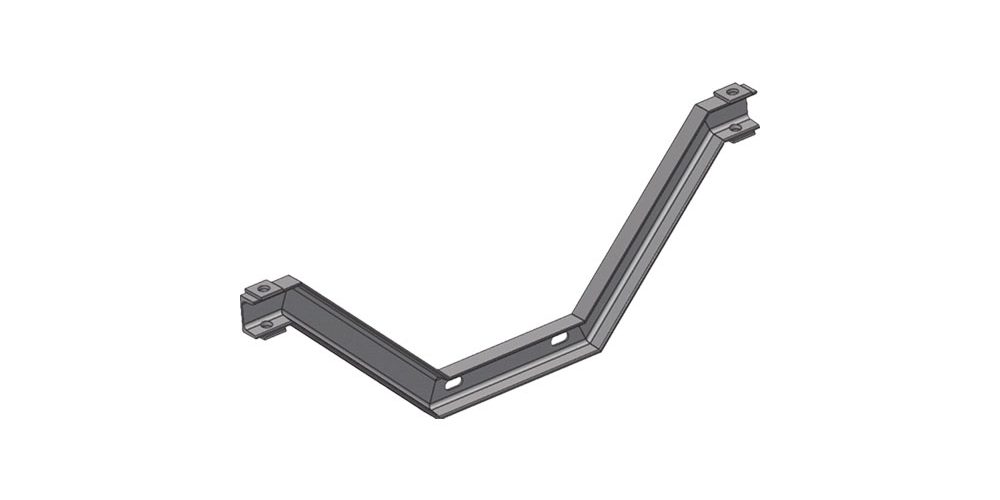

An electrical crossarm is a horizontal support structure used to provide a platform for mounting various electrical components. This helps to ensure the stability and proper functioning of power lines. It provides support to insulators, conductors and hardware in the systems. Electrical crossarm optimize the efficiency and resilience of the process in different conditions. They find use in applications such as telephone companies, electrical utility companies and cable companies. Electrical crossarm may be from materials such as wood, steel or composite materials. These materials are particularly helpful in various applications in South America. This is because the area has diverse weather conditions including high humidity, heavy rainfall and storms. Common types include steel crossarm, composite crossarm, angle arm, tension crossarm and brace crossarm.

Key features of electrical crossarm

The electrical crossarm comprises of various features that help increase support and stability. The specific features vary depending on type of application, environmental factors and costs. The following are the key features of the electrical crossarm.

- Shape and size – the crossarms are available in different shapes and sizes. This helps to accommodate insulator, conductors and hardware.

- Insulator pins – they also have grooves that help to securely hold electrical insulators. This helps prevent electrical current from escaping the power lines.

- Material – they are from materials that help them withstand the various environmental conditions. The selected material depends on factors such as environmental conditions, load bearing requirements and costs.

- Mounting hardware – the crossarms have brackets, mounting holes and attachment points. They help in securing insulators, electrical conductors and hardware.

- Conductor support – they have designs that help support conductors on transmission towers.

- Load-bearing capacity – the crossarms are able to withstand the weight of the equipment they support. They also withstand other forces such as wind, ice and temperature variations.

- Durability – they are also designed for durability and long service life. This helps to reduce maintenance and replacement costs.

- Hardware and accessories – the crossarms work with other hardware for security. These include clamps, connectors and brackets.

- Installation – they provide proper and easy installation through use of various methods.

Selection and installation of electrical crossarm

The selection process helps to ensure the stability and reliability of overhead power lines and utility poles. It involves considering several factors that include material, load-bearing, environmental factors, crossarm type, compatibility, ease of installation and safety features. The installation should also ensure stability and safety. Also, it is advisable to consult with industry experts for guidance whenever in doubt. The following is a basic installation guide for electrical crossarm.

- Preparation – gather all the necessary tools required for installation. These include electrical crossarm, utility pole, insulators, wrenches, fasteners and cotter pins.

- Location selection – determine the suitable location for installing the electrical crossarm.

- Crossarm positioning – place the crossarm in the desired position on the utility pole to ensure that is level and aligned.

- Insert the crossarm pin – insert the threaded end of the crossarm pin through the hole in the crossarm.

- Secure the crossarm pin – thread the non-pointed end of the crossarm pin into the hole. Use wrenches to tighten the crossarm pin securely.

- Insulator installation – secure insulators and hardware using the suitable fasteners. This helps to ensure proper positioning and alignment.

- Installation inspection – perform a visual inspection of the installation. This is to ensure the electrical crossarm, insulators and hardware.

- Documentation – keep detailed records of the installation. This is including photographs, dates and any measurements.

Maintenance and inspection of electrical crossarm

Regular maintenance and inspection help to ensure the longevity and reliable operation. It also helps identify and address issues with electrical crossarms. This is to helps reduce the risk of accidents and power disruption. Additionally, it is advisable to consult with industry experts for professional maintenance and inspection once in a while. The following is a basic guide for maintenance and inspection in South America.

- Establish a regular inspection schedule for crossarms based on usage and environmental conditions.

- Inspect the crossarm for signs of warping, bending or deformation that may compromise the load bearing capacity.

- Ensure it can support the intended loads including insulators, conductors and hardware.

- Verify that the crossarm remains level and properly aligned with the utility pole. Misalignment can affect the integrity of the power lines.

- Examine insulators and hardware attachments for signs of damage or wear. This is to ensure they are securely attached and shows no signs of cracking.

- Check the cotter pins used to secure the crossarm pin are in place and functioning correctly.

- Consider the impact of environmental factors in the region. This includes humidity, temperatures and exposure to sunlight.

- Clean the crossarms to remove debris, dirt and vegetation accumulated on the surface.

- Regularly inspect for rust or corrosion and apply anti corrosion coatings. This is to protect the metal from environmental factors.

- Treat wood crossarms with wood preservatives or coatings to protect against decay and insect damage.

- Examine the hardware such bolts, nuts, washers and cotter pins for signs of wear or loosening.

- Maintain detailed records of all inspections performed. This is including findings and any actions taken based on the inspection results.

Comparative analysis of electrical crossarm

A comparative analysis includes assessing and evaluating the different types and designs of electrical crossarms. It helps to select the best crossarm based on power distribution needs, environmental conditions and infrastructure development. This helps infrastructure developers make informed decisions when selecting electrical crossarm. The following are the factors to include in a comparative analysis in South America.

- Environmental conditions – consider the environmental factors and their impacts. These include high humidity, temperature fluctuations and exposure to UV radiation.

- Load bearing capacity – the crossarms should meet the specific power distribution needs in each region. This includes factors such as power lines, conductor size and wind load.

- Local manufacturing – assess the availability of local manufacturers and suppliers of crossarms. This also helps to help reduce lead times and transportation.

- Renewable energy projects – consider how well the electrical crossarm helps in the expansion of renewable energy projects.

- Future trends – consider emerging trends in power distribution. These influence the designs and functionality of crossarms.

- Infrastructure development – consider the development of infrastructure for reliable power distribution.

- Cost consideration – evaluate the cost-effectiveness of the different crossarm materials and designs. Consider the initial investments, maintenance requirements and expected lifespan.

- Material selection – consider South America’s diverse climate zones such as tropical rainforests and high-altitude regions. Some of the materials include wood, steel and anti-corrosion coatings.

- Local expertise and labour – consider the availability of skilled labour for crossarm installation and maintenance. Local manufacturing impacts the quality and efficiency of power line construction and upkeep.

Certifications and standards in South America

South America has various standards and certifications governing the use of electrical crossarms. They help to ensure safety and reliability od distribution systems and utility pole. These standards vary depending on country as some countries may adapt to international standards. Additionally, the manufacturers and contractors should consult the local authorities for success in the market. The following are the standards and certifications and standards in South America.

- IEC standards – these are global standards for electrical and electronic technologies including electrical crossarms.

- ISO certifications – this certification ensures that manufacturing processes and product quality meet international standards.

- National standards – each country has its own national standards and certification for electrical equipment.

- Local regulatory approvals – manufacturers and suppliers should ensure that their crossarms comply with the specific regulatory requirements.

- Environmental certifications – there may be certifications related to sustainability and environmental impact.

Regional market for electrical crossarm in South America

There are various factors that influence the regional market of electrical crossarms in South America. These factors include similarities and differences in the use, materials, standards and challenges associated with crossarms. The following are the factors that shape the regional market for electrical crossarms in South America.

- Future trends – various trends in power distribution technology such as smart grids. Ensure to assess their potential impacts on crossarm design and functionality.

- Sustainability initiatives – examine the sustainability initiatives related to crossarms materials. Consider the growing emphasis on environmentally friendly solutions.

- Load-bearing capacity – assess the variations in load-bearing capacity requirements. These factors include transmission line voltages, environmental forces and conductor size.

- Challenges and solutions – identify common challenges faced by utilities, contractors and manufacturers in the region.

- Materials and material selection – assess the prevalence of different crossarm materials. Wood, steel and composites. Identify the factors influencing material selection such as availability, cost and environmental conditions.

- Load-bearing capacity – assess the variations in load-carrying capacity requirements. This is depending on factors like conductor size, environmental forces and transmission line voltage.

Frequently asked questions

What is the purpose of an electrical crossarm in power distribution systems?

An electrical crossarm provides horizontal support for electrical components such as insulators, conductors and hardware on utility poles. It helps maintain proper alignment and spacing of these components in overhead power distribution systems.

What are the environmental challenges faced by crossarms in South America?

South America has diverse climates from topical rainforests to high-altitude regions. These include challenges like humidity, temperature fluctuations, UV exposure and corrosion. Ensure to select materials and coatings to address these challenges.