A ground rod coupling is a device used to ensure proper grounding of the electrical infrastructure. It helps protect against electrical faults, lightning strikes and provide a safe path for fault currents to dissipate into the earth. It also helps connect the ground conductor to a ground rod in the grounding system. Ground rod couplings are also engineered to withstand the diverse environmental conditions in Southeast Asia. This helps provide reliable grounding solutions for your power infrastructure. Ground rod coupling is from materials such as coper, brass, steel or bronze. Common types include threaded, clamp-on, compression, exothermic welding and parallel ground rod coupling. They find use in applications such as distribution systems, telecommunication networks and industrial facilities among others.

Key features of ground rod coupling

Ground rod coupling consists of several components that help ensure reliable and low-resistance connections to ground rods. The features also depend on the intended use and type of application. the following are the key features of a ground rod coupling.

- Threaded or non-threaded – threaded couplings have internal threads that allow them to screw onto the threaded end of a ground rod. The non-threaded couplings use clamps, compression mechanisms or other methods.

- Corrosion resistance – the ground rod couplings may have coatings that help the resist corrosion.

- Compatibility – they should also be compatible with the diameter and material of the ground rod used.

- Conductivity – they should provide electrical conductivity to ensure efficient dissipation of electrical energy.

- Durability – they should be durable and capable of withstanding mechanical stress, vibration and environmental factors.

- Temperature resistance – the ground rod coupling should be able to maintain their performance and integrity in extreme temperatures.

- Reliability – the couplings should also maintain a low-resistance connection throughout their service life.

- Cost effectiveness – they should also provide good value and quality performance according to the costs.

Selection and installation of couplings

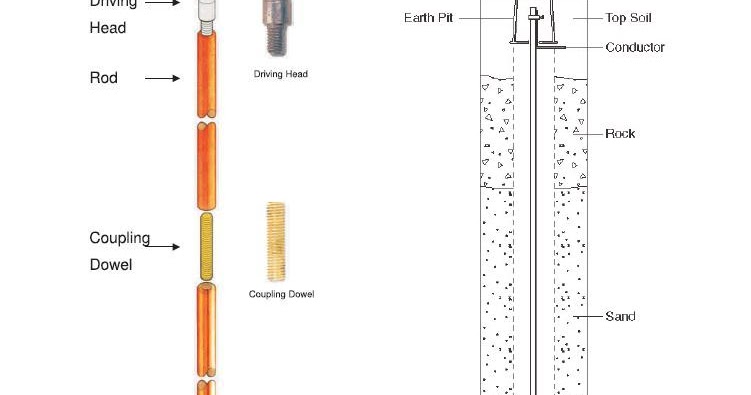

The selected ground rod coupling should ensure effectiveness and reliability of a grounding system. This includes considering several factors such as environmental conditions, electrical conductivity, threaded and non-threaded, corrosion resistance and ease of installation. The installation process should enhance the safety of the system and the workers. Additionally, it is advisable to consult with industry experts to ensure the installation is correct and safe. The following is a step-by-step guide of the ground rod coupling installation.

- Preparation – ensure the work area is clear of any debris and follow all the necessary safety procedures.

- Selection – choose the ground rod coupling that matches the diameter and material of your ground rod.

- Inspection – inspect the ground rod coupling for any visible damage, defects or signs of corrosion.

- Ground rod preparation – clean the threads using a wire brush to remove dirt and rust. This helps to ensure a secure connection with the coupling.

- Attachment – use the right tools and mechanisms to install the ground rod coupling depending on the type of coupling used. This may include threaded or non-threaded ground rod coupling. Ensure a tight and secure connection that facilitates low resistance.

- Ground conductor preparation – expose the bare wire of the ground conductor. This helps to ensure proper connection with the ground rod coupling.

- Ground conductor attachment – connect the exposed ground conductor to the ground rod coupling. This should be according to the manufacturer’s instructions. This may involve clamping, compression or other methods.

- Inspection and testing – inspect the installation to ensure the connections are secure and no loose parts. Perform tests to ensure proper functioning of the grounding system.

- Backfill – backfill the hole around the ground rod to secure it in place and ensure the ground remains vertical and does not shift.

- Documentation – maintain detailed records of the installation including type of ground rod coupling used and specifications.

Maintenance and inspection of ground rod coupling

Proper maintenance and inspection of ground rod couplings ensures the reliability and effectiveness of the grounding system. It also helps identify issues early and prevent potential electrical hazards. Additionally, it is advisable to consult with professionals for periodic maintenance and inspections. The following is a basic guide for maintenance and inspection of the ground rod coupling in Southeast Asia.

- Perform regular inspections to check for signs of damage, corrosion or loose connections.

- Clean the ground rod coupling to remove dirt, debris or corrosion on the coupling using a cleaning solution.

- Verify that the connections between the ground rod coupling and the ground rod are tight and safe. Tighten any loose connections to ensure a secure and low-resistance connection.

- Replace any damaged or corroded couplings to maintain the integrity of the grounding system.

- Perform scheduled inspections of the grounding system depending on the environmental conditions.

- Visually inspect the entire grounding system including ground rod couplings, ground rods and ground rod conductors. Check for signs of physical damage, wear or corrosion.

- Check for signs of corrosion which can reduce the effectiveness of the grounding system. Replace any worn out or affected components of the systems.

- Maintain detailed records of all inspections and maintenance performed. This includes the condition of each ground rod couplings and any corrective actions taken.

Comparative analysis of ground rod couplings in Southeast Asia

A comparative analysis involves evaluating and assessing different types and designs of couplings. It also depends on various factors such as materials, environmental conditions, industry standards and specific regional requirements. Also, it is advisable to consult with industry professionals for guidance on the best selection. The following are the factors to include in a comparative analysis of ground rod coupling in Southeast Asia.

- Material – assess each material used and their advantages and if they suit your application needs. Common materials include copper coupling, bronze couplings and steel couplings. Evaluate their suitability to the diverse environmental conditions in Southeast Asia.

- Environmental conditions – Southeast Asia consists of a wide range of environmental conditions. These ranges from high humidity, tropical climate to coastal areas. A good ground rod couplings should be able to withstand these conditions without degradation

- Industry standards – there are various national and international standards that regulate the use of ground rod couplings in Southeast Asia. Ensure the selected ground rod couplings comply with all the necessary standards and regulations.

- Regional considerations – there may be some specific regional considerations including lightning frequency, industrial applications and infrastructure growth. These factors influence the demand and availability of ground rod couplings in Southeast Asia.

- Cost-effectiveness – compare the different prices and balance the quality, performance and budget considerations.

- Supplier availability – presence of local suppliers and manufacturers may also interfere with the selection process. Evaluate the ease of acquiring spare parts and technical support for maintenance and replacements.

Certifications and standards of ground rod couplings in Southeast Asia

There are various standards and regulations that govern the use of ground rod coupling in Southeast Asia. Some of the countries adapt to international standards while other may vary depending on country. The following are the key certifications and standards relevant to ground rod couplings.

- IEC standards – these include standards for electrical components such as ground rod couplings. They also relate to lightning protection components used.

- Local electrical codes – each country has its own set of regulations and electrical codes governing ground rod couplings.

- Local industry standards – these are standards for grounding systems that apply to ground rod couplings. They are mainly developed by local industry associations or regulatory bodies.

- Corrosion resistance standards – these regulate the use of ground rod couplings in areas with high humidity.

- Lightning protection standards – the couplings used for lightning protection systems should comply with lightning protection standards.

Regional market for rod couplings in Southeast Asia

There are various factors that influence the demand and availability of ground rod couplings in Southeast Asia. These factors may include economic development, infrastructure projects, industrial growth ad need for electrical safety. Additionally, it is advisable for manufacturers to observe the industry trends for guaranteed success. The following are the factors that shape the regional market for ground rod couplings.

- Electrical grid expansion – growing demand for electricity and expansion of the electric grid increases the demand for ground rod couplings.

- Industrial growth – the development of the wide range of industries requires the use of ground rod couplings for safety. This includes manufacturing, petrochemicals and telecommunication.

- Local manufacturing and supply chain – the availability of local manufacturers and suppliers of ground rod couplings impact the regional market.

- Competition – the regional market is competitive with local and international manufacturers and suppliers vying for market share.

Frequently asked questions

What is a ground rod coupling and its importance in electrical systems?

This is a component used to connect ground rods to ground rod conductors in an electrical grounding system. It ensures safety by dissipating electrical energy and providing a low-resistance path to the ground.

What are the key considerations for selecting the right ground rod coupling in Southeast Asia?

Consider the material compatibility, corrosion resistance, compliance with standards, ease of installations and suitability to various applications.

Which materials are suitable for ground rod couplings in Southeast Asia?

Materials such as copper, bronze and corrosion resistant steel helps provide resistance to corrosion in high humidity and salt exposure.