Argentina is emerging as a global leader in South America’s liquefied natural gas business. The Vaca Muerta shale formation in Patagonia could contain over 300 trillion cubic feet of recoverable natural gas. This is enough to support Argentina’s LNG ambitions. Strategic infrastructure expansion and increased investor interest are key drivers of LNG production. YPF, Petronas, and Shell expect to export up to 25 million tons of LNG per year by 2030. There have also been significant investments in floating LNG plants, which might give flexible capabilities by 2027. LNG production and export play an important part in the transition to renewable energy. This is consistent with Argentina’s goals for reducing emissions while maintaining electricity reliability. LNG is considered a bridge fuel as countries decarbonize the energy sector. Cryogenic yoke plates ensure the structural integrity, safety, and efficiency of pipelines, storage tanks, and export terminals.

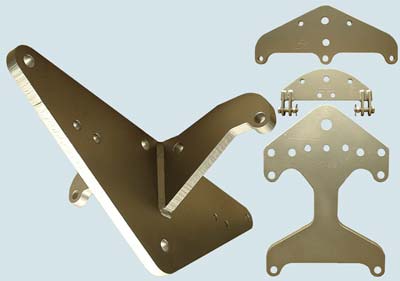

Yoke plates aid in the stability of extremely low-temperature conditions as Argentina ramps up production. The usage of these plates prevents leaks and structural breakdowns in harsh environments. This helps to reduce downtime in LNG operations. Pipeline anchoring systems serve as structural anchors that distribute mechanical loads across supports. LNG cryogenic systems need leak-proof flanges and couplings despite high temperature changes. The plates enhance flange connections to prevent leakage in LNG storage tanks and loading arms on LNG ships. Stainless steel yoke plates can withstand brittleness at cryogenic temperatures.

Increasing Argentina’s LNG output and exports with yoke plates

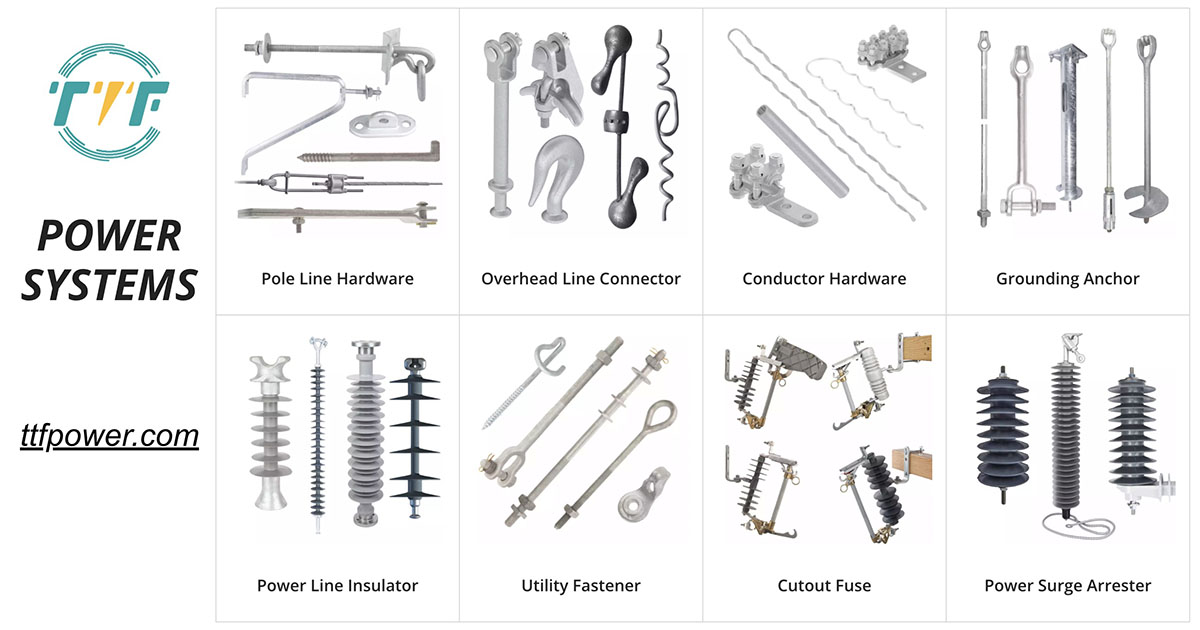

Yoke plates are components of high-voltage power transmission systems. They link many insulator strings or suspension clamps to a single point on a transmission tower. The plates serve to evenly distribute mechanical stresses and keep electrical insulation intact under extreme stress. Using yoke plates helps to assure the dependability and safety of the electrical infrastructure that drives the LNG value chain. Argentina should invest in sturdy, dependable electrical components like yoke plates to support its LNG goals. The following are the roles of cryogenic yoke plates in LNG production and export.

- Ensuring power stability at LNG facilities—LNG plants need round-the-clock power for continued efficiency. Yoke plates hold insulators in position under extreme load, prevent mechanical failure, and reduce the risk of power outages. This could reduce disruptions of gas processing or export schedules.

- Reinforcing remote energy infrastructure—Argentina’s gas extraction is mostly in remote regions. Transporting electricity across long distances needs extra-strong support structures. The use of yoke plates helps balance stress from high-voltage conductors and environmental forces.

- Enabling grid expansion for export growth—with the increasing scaling up of export infrastructure, new LNG facilities need new grid connections. Yoke plates help in expanding the national power grid to reach export terminals and support off-grid power setups.

- Pipeline support and load distribution—LNG pipelines experience thermal contraction, which can risk misalignment. Cryogenic yoke plates act as structural anchors to distribute mechanical loads.

- Vibration and seismic resistance—compressors, pumps, and LNG carrier loading systems generate vibrations. Yoke plates dampen vibrations to reduce fatigue on pipelines. This is crucial for Argentina’s coastal LNG terminals facing seismic risks.

Key impediments to Argentina’s LNG production and export

Argentina has the potential to be a major LNG exporter, with reserves such as the Vaca Muerta shale formation. It, however, poses technical, financial, and political hurdles that may impede growth. Argentina must address infrastructure shortages, regulatory uncertainty, economic volatility, and technical obstacles to achieve a viable LNG future. The following are the issues facing LNG production.

- Insufficient infrastructure—Argentina lacks the infrastructure needed to process and export LNG at scale. Key challenges include limited LNG terminals, inadequate midstream capacity, and port facilities.

- High capital requirements—pipelines, liquefaction facilities, export terminals, and power systems—demand upfront costs. The key challenges include foreign investors, fluctuating exchange rates, and political risks.

- Policy instability—Argentina often has sudden regulatory changes, subsidy shifts, and nationalization threats. The ongoing issues include a lack of long-term policies for LNG and opaque rules for LNG pricing and export contracts.

- Energy transmission blocks—LNG operations need a massive, continuous electricity supply. However, aging power grids and insufficient transmission lines. High-quality yoke plates and insulator ties face stress due to under-maintained systems.

- Technical challenges—tech such as cryogenic LNG storage and handling need high-precision systems. Long distances from production fields to ports increase transport costs. This may lead to delays, higher operational costs, and risk of equipment failure.