A washer is a specific component used in the assembly of hardware to support and secure conductors, insulators and other equipment. It is a circular, flat piece of metal with a hole in the center which allows installation of bolts and other fasteners. The main purpose of washers is to distribute the load and provide a smooth surface for the nut to tighten against. This is to prevent damage to the material clamped and ensure a secure connection. Use of washers with nuts and bolts help to create stable and durable connections in the construction. They are from high strength materials like stainless steel to maintain the integrity of South American applications. Examples include lock washers, spring washers, wave washers and square washers. They find use in applications such as construction, electrical equipment, transmission lines and railway industry.

Key features of a washer

Washers have various features that help to ensure the effectiveness of various applications. These features make the washers a suitable choice in various applications in south America. The following are the key features of washers.

- Load distribution – washers help to distribute the load of a fastener over a larger surface area. This helps to prevent damage of the material fastened to ensure a more stable connection.

- Vibration resistance – several washers provide an extra layer of security in applications that need stability. Washers such as lock washers and split ring washers are able to resist loosening caused by vibrations.

- Insulation – they are also from insulating materials to prevent electrical conductivity between different components.

- Material – washers are from various materials like metal, rubber, nylon and plastic. The choice depends on load capacity, insulation needs and resistance to environmental factors.

- Design – they are available in various designs to suit specific applications in the industries.

- Alignment compensation – some washers provide a spring-like action rewarding for axial play, misalignment and thermal expansions.

- Corrosion resistance – they are also available in corrosion-resistant materials. This is to maintain the integrity of the integrity of the connection.

- Ease of installation – the washers are less complicated in design for ease of installation and fastening.

- Cost effectiveness – washers are highly affordable which makes them widely used in a variety of industries and application.

Selection and installation of a washer

Right selection of the washers helps to ensure the stability and functionality of the fastened components. It involves consideration of factors such as type of fastener, material compatibility, load distribution size and dimension, ease of installation and costs. The installation is a straightforward process that ensures the stability and integrity of the fastened components. Additionally, it is advisable to consult industry experts for guidance in complex installations. The following is a general installation process of the washers.

- Preparation – gather all the necessary materials required for the installation. This is including the correct type and size of washers. Also ensure you have all the required safety equipment including gloves and glasses.

- Fastener preparation – ensure all the fasteners are clean and in good condition free from any debris or rust.

- Washer selection – select the washer that best suits your application needs. This is basing on the load distribution, vibration assistance and material compatibility.

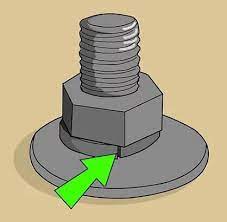

- Place the washer – slide the washer on the fastener before installation.

- Fastener positioning – insert the fastener through the washer and the material to fasten until properly cozy.

- Hand tightening – hand tighten the fastener until it is comfortable against the material.

- Use tools – use the appropriate tools to tighten the fasteners such as wrenches or sockets.

- Check alignment – ensure the washer is properly aligned and the load distributed evenly.

- Inspection – visually inspect the connection to ensure the washer is in place.

Maintenance and inspection of washer

Proper maintenance and inspection help to ensure the continued reliability and functionality of the fastened components. It also helps to identify and address issues that could lead to potential failures and accidents. The diverse environmental conditions of South America influence the frequency of the activity. Additionally, it is advisable to conduct professional maintenance and inspections once in a while. The following is a basic guide on the maintenance and inspection of washers in South America.

- Regularly inspect the washers for visible signs of damage like cracks, warping or corrosion.

- Ensure the washers meet the specified dimensions and size requirements. This is to enhance the stability of the connection.

- Check

- Check the lock washers or other locking features to resist loosening due to vibrations.

- Ensure the washer material is in good conditions to ensure the insulating material is not deteriorated.

- Inspect the fastened components to ensure even load distribution. Misalignment of washers can cause uneven stress on the materials.

- Periodically clean the washers to remove dirt, debris and any other corrosive substances. This is important in environments with high humidity or exposure to corrosive elements.

- Apply corrosion prevention measures especially in areas with salt exposure. Consider using corrosion-resistant washers such as those made of stainless steel.

- Apply lubrication to the fasteners and washers to help reduce friction, prevent galling and improve overall performance of the connection.

- Inspect the washers regularly for signs of wear, deformation or damage. Place any washers that show signs of degradation to maintain the integrity of the fastened.

- Periodically check the tightness of fasteners to ensure they are properly tightened. Loose connection can lead to inefficiency and potential hazards.

- Maintain records of dates of installation and when inspections or maintenance activities. This is to help establish a preventive maintenance schedule.

Comparative analysis of washers in South America

A comparative analysis of washers includes assessing and evaluating factors such as selection, usage and performance. It also includes considering the various types, designs and brands of the washers in South America. Also, it is important to consult with industry professionals for guidance on the best washer for your project. The following are the factors to include in a comparative analysis on South America.

- Material selection – explore the various materials used for washers. This is including steel and stainless steel for corrosion resistance.

- Industry applications – Examine the major industries using washers. This isincluding agriculture, mining, manufacturing and construction.

- Corrosion resistance – assess the importance of corrosion resistance in washers especially in areas with high humidity.

- Technological advancements – investigate whether there is a trend towards adopting newer washer technologies. This includes innovative materials or designs and how they impact performance.

- Costs – analyze the cost considerations associated with the selection of washers. This may influence the choice between standard and specialized washers.

- Environmental factors – consider the wide range of climates in South America from tropical rainforests to arid regions. Analyse how factors such as humidity, temperature variations and exposure to salt.

Certifications and standards in South America

These standards hep to ensure the quality, safety and reliability of washers in South America. Also, it is important to ensure the selected washer meets all the necessary standards and certifications. Each South American country has their own set of standards for washers. The following are the common certifications and standards in South America.

- ISO standards – this standard specifies the dimensions of plain washers. This to ensure the quality and performance of the washers in various applications.

- DIN standards – this is a German standard that specifies dimensions for flat washers. This is including various types which differ in their outer diameters.

- ASTM standards – this covers round and miscellaneous shape flat washers made of various materials including carbon steel and alloys steel.

- Local and regional standards – this includes standards for each South American country regarding various products.

- Industry specific certifications – these includes standards like API and UL for safety and performance of washers.

Regional market for washers in South America

There are various factors that influence the demand and supply of washers in South America. It also depends on factors such as supply, demand and market trends. Additionally, it is important to understand these market dynamics that influence the market. The following are the factors that influence the regional market for washers.

- Market size and growth – investigate the overall market size for washers in south America. Analyse historical trends and project future growth based on factors such as industrial development and economic indicators.

- Industry verticals – examine the demand for washers across different industry verticals. This includes various applications in the industry.

- Construction sector – assess the growth of the construction sector in south America and its impact on the demand for washers.

- Automotive industry – analyze the automotive market and its influence on the demand for washers.

Frequently asked questions

Common types of washers used in south America include flat washers, lock washers, spring washers and special-purpose washers like fender washers.

Common materials include steel, stainless steel and sometimes materials with specific properties like corrosion resistance or electrical insulation.

The construction boom in south America positively impacts the demand for washers as they are essential in various construction application for load distribution and stability.