A V-type crossarm is a device used to provide mechanical strength and stability to the line. It is also known as a V-crossarm or a V-arm. Best materials for V-crossarm for transmission lines include wood, steel or fiberglass. These materials offer resistance to corrosionand durability. The device forms in a V-shape that provides extra strength and rigidity. It helps maintain the required separation between the conductors and prevents contact. Also, this helps them to withstand the forces exerted by wind, ice and other environmental factors. The device works on medium and high – voltage transmission lines.

Components of the V-type crossarm

Specific components and configurations of the V-type crossarm depend on various factors. These factors include design standards, transmission line requirements and local regulations and standards. Among the components listed below, there are other components such as safety chains, lightning arrestors and markers. The following are the main components of a V-type crossarm.

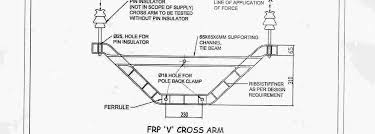

- Main body – the main crossarm provides support and strength to hold the conductors and other components in place.

- Arms – these are the two main beams that form the V-shape made from wood, steel or fiberglass.

- Legs – these are the vertical supports that connect the arms to the pole.

- Insulators – insulators install on the attachment points of the crossarm to help prevent the flow of faulty current.

- Fasteners – hardware such as nuts, bolts and washers help to securely attach the crossarm to the pole.

Types of V-type crossarms

There are various types of V-arms used on the overhead transmission lines. The types vary depending on voltage levels, conductor size, environmental conditions and specific requirements of the transmission line. The following are the common types of V-arms used on the transmission lines.

Single-span crossarms – this are the simplest types of crossarms that have a single span between he two arms. These are mostly used on low-voltage applications.

Double-span crossarms – these crossarms have two spans between the two arms which make them more stable. They are mostly used for high voltage applications which make them more expensive.

Tapered crossarms – tapered V-arms have a tapered shape which allows them to reduce the wind load on the crossarm.

Angled crossarm – these have angled arms which allows them to support conductors at different angles.

Combination crossarm – these are crossarms that combine two or more types of V-arms. This helps them work in different applications for different purposes.

Applications of V-type crossarms

V-arms find use in various applications in the industry. The specific application area depends on the requirements of the application, voltage level and conductor type. It may also depend on the standards of the power grid or utility company. The following are the common applications of the V-type crossarm.

- Overhead power lines – V-type crossarms support conductors on overhead power lines in medium to high transmission lines. This is because they are more stable than other crossarms.

- Telephone lines – V-type crossarms support conductors on telecommunication cables such as fiber optic cables or telephone lines.

- Street lights – the crossarms support street lights, appliances and other electrical needs.

- Crossings and connections – the arms work in situations where transmission lines intersect or cross over each other.

- Transmission line upgrade – V-type crossarms work in line upgrade to provide extra support. They also ensure the structural integrity of the upgraded lines.

V-type crossarm installation guide

Installation process varies depending on the exact design standards, equipment used and requirements of the utility company or power grid. The installation process should meet the local standards and regulations of the application. Additionally, it is advisable to consult the relevant installation guidelines, engineering specifications and safety regulations. The following is a basic installation procedure of V-type crossarm.

- Prepare the installation area by clearing the area around the pole or tower where the crossarm will install and make it safe and accessible.

- Position and align the V-type crossarm on the pole at the center and at appropriate height an angle.

- Securely attach the crossarm to the pole using the suitable hardware such as bolts, nuts and washers. This help prevent movement or sagging of the lines.

- Mount the insulators on the attachment points of the crossarm. They should be properly aligned and spaced according to the design specifications and requirements.

- Attach the conductors to the insulators and ensure proper tension and alignment.

- Inspect the installation for proper connections and alignment. Conduct testing to ensure the integrity of the insulation and proper electrical performance.

Selecting the best V-type crossarm

The selected V-type crossarm for transmission lines should meet the specific requirements of the project. The suitable crossarms ensure the reliability and efficiency of power distributions. It is advisable to consult with industry professionals for guidance on the most appropriate V-type crossarm for your project. The selection process involves several factors to consider which are as discussed below.

- Consider the cost of the product by assessing the initial investment, maintenance costs and expected lifespan of the crossarm.

- Consider the expected service life of the crossarm and the required maintenance.

- Verify that the crossarm material and design can withstand the expected mechanical loads and stresses.

- Determine the voltage level and load capacity of the transmission lines. Ensure the V-type arms can handle the mechanical loads and stresses.

- Consider the environmental conditions such as humidity, salt exposure, temperature variations and corrosive agents present in the installation area.

- Determine the required dimensions of the V-type crossarm based on conductor spacing, clearance requirements and electrical clearance.

- Select the suitable materials based on the environmental conditions, corrosion resistance and strength requirements.

- Ensure the chosen crossarm meets the regulatory compliance standards for V-type crossarms. This is to ensure safety, reliability and performance.

- Select V-type crossarms from reputable manufacturers and suppliers with track record of producing high quality products.

Frequently asked questions

What is V-type crossarms as used on power transmission lines?

A V-type crossarm is a device used in construction of power transmission lines to provide support for conductors. They also provide mechanical strength and stability to the transmission lines.

What are the common types of V-type crossarms?

Common types of the V-type crossarm include single-span crossarms, double span crossarms, angled crossarms, tapered crossarms and combination crossarms. They have different designs to meet different requirements.

What are the common advantages of using V-type crossarms?

V-type crossarms offer various benefits that include mechanical strength, electrical insulation, conductor alignment and spacing, durability and cost effectiveness. These are factors to consider when selecting the crossarms for your application.

What are the disadvantages of V-type crossarms?

The V-type also feature several disadvantages which include limited load capacity, material degradation, limited insulator spacing, complex installation and heavier in weight. These factors make the selection process easier and less tiring.