A thimble eye bolt is a type of fastener used in various applications that need secure connection point. It has a loop at one end and a threaded shank at the other end. It is also known as a thimble bolt or thimble screw. The thimble eye creates a closed, circular attachment point. This point allows for the bolt to work with ropes, cables, chains or other connectors. They are from materials such as carbon steel, stainless steel or galvanized steel. These materials provide strength and corrosion resistance. Thimble eye bolts work in applications such as rigging and lifting, marine and boating, outdoor recreational use, overhead lifting and wire rope assemblies.

Components of thimble eye bolt

Thimble eye bolt consists of several components that contribute to their effectiveness and functionality. The components work together to create a reliable and secure attachment point. This makes it a valuable and practical choice for many different tasks. The components are as discussed below.

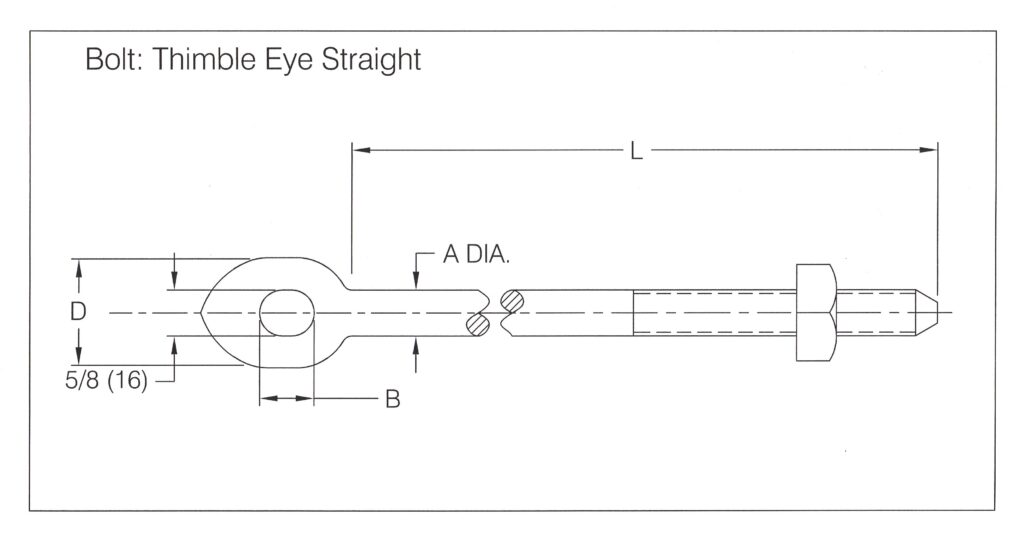

- Thimble eye – this is the main component of the thimble eye bolt that provides a rounded and smooth attachment point.

- Threaded shank – this is the threaded part of the bolt that allows it to fastened into a threaded hole.

- Threads – these are helical ridges on the shank of the bolt to enable the thimble eye bolt to screw into a matching threaded hole.

- Threaded end- this is the part that inserts into the corresponding threaded hole or nut.

Types of thimble bolt

Thimble eye bolts come in various types and designs for specific applications. Each type of thimble eye bolt serves a specific purpose and offer unique features to address different application needs. It is essential to consider factors such as load capacity, material, corrosion resistance and compatibility with the application’s requirements. The following are the common types of the thimble eye bolt.

- Standard thimble eye bolt – this is the most used type of thimble eye bolt. It features a simple loop or eye at one end and a threaded shank at the other end.

- Shoulder thimble eye bolt – this type has a shoulder between the eye and the threaded shank to provide a flat and smooth surface.

- Heavy-duty thimble eye bolt – these types are able to withstand higher loads for applications that require a robust and durable connection point.

- Swivel thimble eye bolt – swivel thimble eye bolt has a swiveling eye that allows for greater flexibility and movement of the attached cable or rope.

- Eye-and-jaw thimble eye bolt – this features a combination of an eye at one end and a jaw on the other end.

- Eye-and-hook thimble eye bolt – this bolt features an eye at one end and a hook at the other end. This is to provide an easier way to attach and detach from other components.

Applications of thimble eye bolt

Thimble eye bolt find use in various applications in the industry to increase reliability and efficiency. The specific type used depends on various factors such as specific application requirements, load capacity and the intended use of the bolt. Also, it advisable to consult with industry professionals on the specific type of bolt to use based on your application requirements. The following are the common application areas of the thimble eye bolt.

- Rigging and lifting – thimble eye bolts help in rigging and lifting applications. This is by acting as attachments for lifting slings, wire ropes or chains.

- Marine – thimble eye bolts act as tie-down points for securing lines or attaching sails and rigging.

- Outdoor and recreational use – thimble eye bolts work in camping, rock climbing and outdoor activities.

- Construction and building – the bolts help to attach cables or ropes to structures or as anchor points for scaffolding.

- Overhead lifting – thimble eye bolts help to suspend equipment or loads securely.

- Wire rope assemblies – thimble eye bolts help in wire rope assemblies for creating loops and attaching fittings.

Installation of thimble bolts

The installation of thimble eye bolts should ensure safety, secure and reliable attachment. Proper installation and maintenance are vital to ensure the thimble eye bolt performs its functions safely and effectively in your specific application. Additionally, it is advisable to consult with a qualified professional if unsure about the installation process. The following is the basic process used to install the thimble eye bolt.

- Prepare the work re and ensure all the necessary tools and materials are readily available.

- Identify the location where you want to install the thimble eye bolt and ensure it provides a secure and stable anchor point for your intended use.

- Drill suitable sized holes that matches the diameter of the threaded shank of the thimble eye bolt.

- Insert the threaded end of the thimble eye bolt into the prepared hole or threaded hole.

- Tighten the bolt using a wrench and apply the suitable amount of torque to ensure a secure and safe connection.

- Attach the cable, rope or chain after tightening the bolt and ensure the attachment is properly secured and there is no slack in the line.

- Test the installed thimble eye bolt and the attached line to ensure that it can bear the intended load and functions as expected.

- Conduct regular inspections and check for signs of wear, damage or loosening and perform any necessary maintenance.

Selecting the best thimble eye bolt

Evaluate the applications needs to ensure you select the best thimble eye bolt for your specific project. Investing in the right thimble eye bolt contributes to the reliability and longevity of your anchoring and lifting applications. Additionally, it is advisable to consult with industry professionals for guidance on the best thimble eye bolt depending on your application needs. The following are the factors to consider when selecting thimble eye bolt for your application.

- Select thimble eye bolt for reputable manufacturers known for producing high quality products.

- Consider the available space for installing the thimble eye bolt and choose a bolt with a compact design that can fit the available area.

- Consider the swiveling capability of the bolt required to allow for rotation or pivoting.

- Select the bolt made of materials with enhanced corrosion resistance. This helps in outdoor applications or marine environment.

- Ensure that the thimble eye bolt meets the relevant industry standards to guarantee quality and performance.

- Determine the maximum load weight that the thimble eye bolt will need to support to ensure safety and reliability.

- Choose a thimble eye bolt with the suitable size and diameter to fit the intended anchor point and cable, rope or chain.

- Select a finish or material that matches the desired aesthetics especially in exposed installations.

Frequently asked questions

What is a thimble eye bolt as used in overhead transmission lines?

A thimble eye bolt is a type of fastener used to secure a connection point or anchor point. It has an eye, threaded shank and a threaded end that allow for use with ropes cables or other connectors.

What are the advantages of the thimble eye bolt?

Thimble eye bolts offer several benefits that makes them a valuable choice in various applications that need secure and reliable attachment points. These benefits include load capacity, corrosion resistance, swivel capability, durability, easy installation, enhanced safety and compliance with standards.

What are the disadvantages of using thimble eye bolts?

Thimble eye bolts have several limitations to consider in certain applications. These include limited rotation, attachment options, corrosion, limited aesthetics, installation complexity and requires regular maintenance and inspection.