U-bolts are types of a fastener used to secure objects to a support in various applications. These bolts are an essential part of the hardware used to hold conductors, insulators in place. The U-bolt consists of curved shape that resembles the letter “U”. This design allows it to wrap around a specific component or section of the transmission line and secure it in place. U-bolt is from materials such as stainless steel or galvanized steel. These materials are suitable for use due to their corrosion resistance for the humid climate of southeast Asia. They work in applications such as automotive industry, electrical industry, construction and telecommunication.

Components of U-bolt

The U-bolt components are from high quality materials and meet the safety standards. The specific components of a U-bolt vary depending on the application and materials used. There are three main components of the U-bolt as discussed below.

- U-shaped bolt – this is the main part of the U-bolt that gives the fastener the name. It wraps around the item such as conductor or insulator for security.

- Threaded arms – the bolt has two arms extending from each end of the U-shaped body to secure the U-bolt in place.

- Nuts – nuts help to secure the U-bolt to the structure to create a secure and adjustable connection.

- Washers – washers help to distribute the load evenly and prevent the nuts from damaging the object.

Types of U-bolts

U-bolts come in different designs and configurations for particular applications in the industry. The specific type of U-bolt selected depends on the material’s strength, diameter, thread size and coating. This ensures the U-bolt meets the demands of the intended application. The right type of U-bolt ensures secure and reliable connections in various industries. The following are the common types of U-bolts in the industry.

- Round U-bolt – this is the most basic type of U-bolt that has a rounded U-shape. It works for applications such as securing pipes, rods or cables.

- Square U-bolt – this bolt has a square-shaped U-bend designed to secure square or rectangular objects.

- Semi-round U-bolt – this type of U-bolt has a semi-circular shape between the round and the square U-bolts. It helps in securing objects that have a partial round or curved profile.

- Anchor U-bolt – these have an extended leg meant to embed into concrete or other solid materials. They help to secure pipes, poles or structural elements during construction.

- Bent U-bolt – bent U-bolts have a bent shape that provides flexibility in applications where the attachment points do not align properly.

- V-bolt – these have a V-shape instead of a U-shape used for holding objects with rounded surfaces such as cylindrical pipes or poles.

Applications of U-bolts

U-bolts find use in various applications across industries due to their versatility and ability to provide secure fastening solutions. The design and type of U-bolt used in a particular application will depend on a series factors. These factors include need of the application, load requirements and materials used. Additionally, it is crucial to consult with industry professionals on the best type to use for your application. The following are the common application areas of U-bolt.

- Automotive industry – U-bolts help to secure several components in automotive applications.

- Construction – U-bolts secure pipes, conduits and other materials to structural supports and in concrete anchoring.

- Electrical industry – these bolts work in the electrical industry to secure cables, wires and conduits to transmission towers and utility poles.

- Telecommunication – U-bolts secure antennas and communication equipment to masts or poles in telecommunication installation.

- Oil and gas industry – these bolts fasten pipes, flanges and other equipment in oil and gas facilities.

- Marine industry – in marine applications, U-bolts secure hardware such as cleats, eye bolts or blocks to the deck or hull of boats and ships.

U-bolt installation guide and tips

The installation process of the U-bolt varies depending on the application and the equipment involved. The installation process should enhance safety and reliability of the overhead lines. Additionally, it is advisable to consult industry professionals for guidance on the installation process whenever in doubt. Also, follow manufacturer’s guidelines and safety recommendations when installing U-bolts. The following are the steps involved in the installation process.

- Ensure you have the suitable U-bolt size and type for your application which should fit around the components.

- Place the U-bolt around the component to make sure it centers and properly aligns.

- Add washers if necessary for your application to distribute the pressure evenly on the clamping surface.

- Start threading the nuts onto the arms of the U-bolt and hand-tighten them until they snug against the washers and the component.

- Tighten the nuts using the necessary tools such as a wrench and apply equal pressure on both the nuts. This is to maintain balance and avoid twisting the U-bolt.

- After installation perform a final inspection to verify that the U-bolt installs correctly and all nuts are properly tightened .

Selecting the best U-bolts

Selecting the best U-bolts for your application involves considering several factors to ensure security and reliable fastening solutions. This ensures you select the U-bolt that best suits your application needs for effective fastening solutions. Additionally, it is advisable to consult the industry experts in the industry for guidance on the type and design to use depending on your application. The following are the factor to consider when selecting the best U-bolt.

- Determine the specific application and use case for the U-bolt by considering factors such as the type and shape of the components you need to secure.

- Choose a material that offers the required strength and corrosion resistance for your application. For humid areas such as the southeast Asian countries, use U-bolts made from materials such as galvanized or stainless steel.

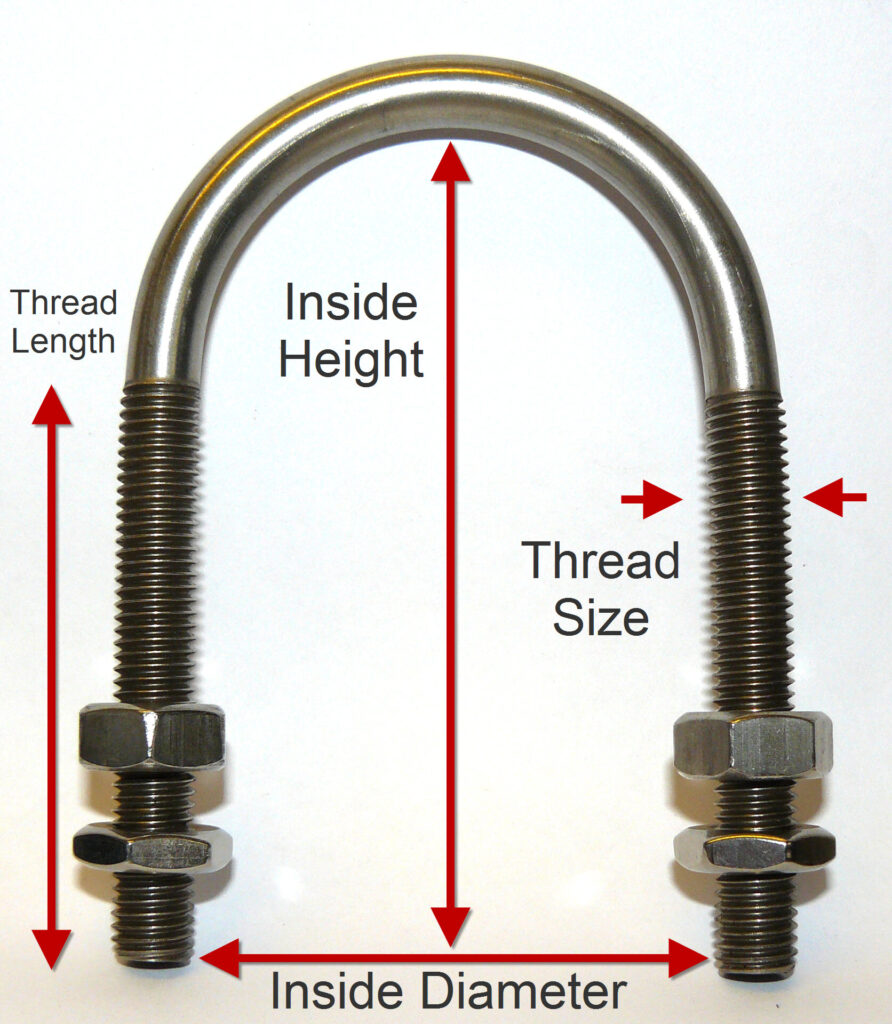

- Ensure the U-bolt is the correct size and dimensions for your application by measuring the width and diameter of the component you need to secure.

- The thread size of the U-bolt should match the nuts you intend to use and check the threading specifications to ensure compatibility.

- Consider the load capacity and strength requirements of your application which should handle the expected load.

- Ensure the selected U-bolt complies to the relevant industry standards to ensure safety and reliability.

- Choose U-bolts from reputable manufacturers known for producing high-quality fasteners.

Frequently asked questions

What is a U-bolt as used in overhead transmission lines?

A U-bolt is a specialized type of fastener used to secure components such as conductors and insulators to supporting structures.

What are the benefits of using U-bolt fasteners?

U-bolt offer several benefits and advantages such as secure fastening, versatility, adjustability, ease of installation, durable materials, cost-effective, load -bearing capacity, resistance to vibration and widely available. These factors make them a popular choice for various applications.

What are the limitations of using U-bolt fasteners?

U-bolt has various disadvantages to address for specific application to ensure safe and effective usage. These include fatigue, limited load distribution, complex installation, corrosion concerns, limited adjustment range, vibration loosening and limitation to specific shapes.