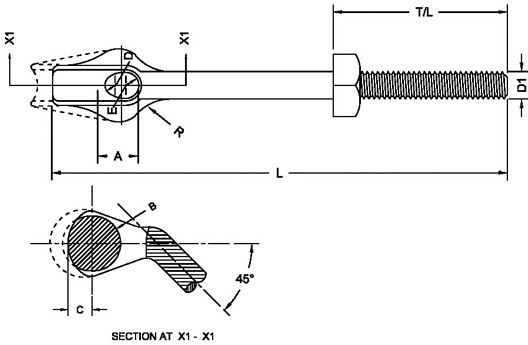

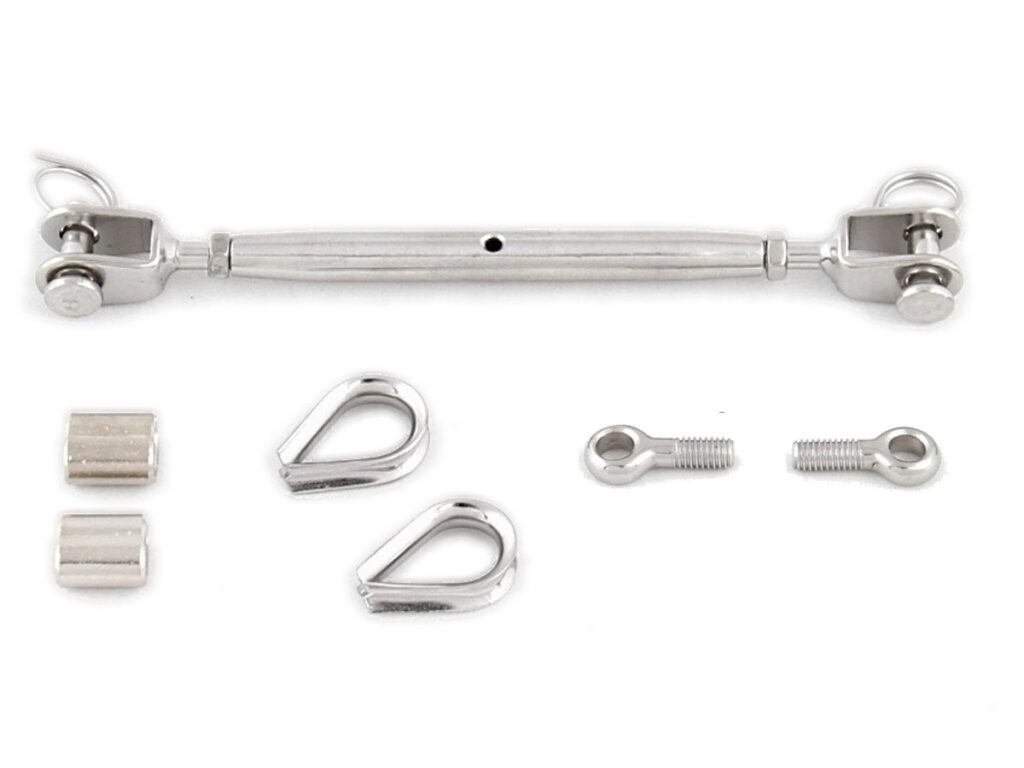

A thimble eye bolt is a hardware used to attach guy wires to utility poles or towers. It helps in the maintenance and construction of overhead transmission lines. The thimble eye bolt has a loop or eye at one end. The eye or design provides a secure and stable connection. The loop at the end allows for easy attachment and adjustment of the guy wire tension. It is from durable materials such as steel or stainless steel. These materials help to ensure strength and corrosion resistance in harsh environments. The innovation of thimble eye bolt materials to hep ensure optimal performance in South American countries. Common types include forged thimble eye bolt, straight thimble eye and shouldered thimble eye bot. They find use in applications such as overhead transmission lines, electrical power distribution, telecommunication and antenna mast installation.

Key features of thimble eye bolt

The various features of thimble eye bolt help to provide stability and support for overhead transmission lines. These features help to ensure safety during use in various applications in the field. The following are the key features of thimble eye bolt.

- Thimble eye design – the thimble-shaped loop at one end allows for easy attachment of guy wires to provide a secure connection point.

- Load capacity – thimble eye bolts are available in different load capacities. This is to ensure safety and performance.

- Types and sizes – they are also available in various types and designs to accommodate different wire diameter and loads.

- Shouldered design – this design between the eye and the threaded portion helps to distribute loads more evenly. It also helps to reduce stress concentrations for longer lifespan.

- Ease of installation – they also have easy installation designs that contribute to their performance in various applications.

- Material – the bolts are from durable materials that help to ensure strength and corrosion resistance in various applications.

- Corrosion resistance – they also have coatings with materials like galvanized zinc or other corrosion resistant finishes.

- Forged construction – forged bolts help to enhance their strength and durability to help in heavy-duty applications.

Selection and installation of thimble eye bolts

Proper selection of thimble eye bolts helps to ensure its suitability for various applications. It also helps to ensure the selected thimble eye bolts meets the specific requirements of your application. It includes considering various factors such as costs, material, corrosion resistance, type of thimble eye bolts, wire diameter compatibility and installation needs. The installation requires careful attention to ensure a secure and reliable connection. The following is general installation process of the thimble eye bolts.

- Preparation – collect all the necessary tools required for the installation. This includes thimble eye bolt, guy wire, wrench, socket set, torque wrench and level. Select the bolt that meets the specific requirements of your application.

- Check compatibility – ensure the thimble eye bolt is compatible with the diameter of the guy wire is properly secured.

- Prepare the installation site – identify the location on the structure where the thimble eye bolts will install. Remove any obstructions and ensure the installation is clean.

- Positioning – position the thimble eye bolt in the desired location. Ensure the thimble end faces outward and easily accessible.

- Guy wire insertion – thread the guy wire through the thimble eye of the bolt and ensure there is enough slack for adjustment.

- Secure with nuts – thread the provided nuts onto the threaded end of the thimble eye bolts. This is using a wrench to tighten the nuts securely.

- Adjust tension – adjust the tension of the guy wire to the desired level to provide proper support and stability.

- Tension adjustment – use a level to ensure the thimble eye bolts and attached guy wire is properly aligned to ensure the structural stability.

- Check alignment – use a level to ensure the thimble eye bolt is properly levelled.

- Final tightening – tighten the nuts and ensure proper alignment and tension the secure connections.

- Inspection – perform a visual inspection to ensure all components are securely fastened. This is to ensure there is no loose connections.

- Documentation – keep records of the installation details including the torque applied.

Maintenance and inspection of thimble eye bolts

Proper maintenance of the thimble eye bolt helps to ensure long term performance and stability of the structures. It also helps to identify and address issues that could lead to potential issues. The frequency depends on the diverse weather conditions in South America. The following is a basic guide for maintenance and inspection of thimble eye bolts in South America.

- Conduct regular visual inspections to check for signs of wear, corrosion or damage. Check for any deformations in the thimble eye loop.

- Check for signs of corrosion and clean using a wire brush. Consider applying a rust inhibitor or coating.

- Ensure the tension in the guy wire attached to the thimble eye bolts within the specified range. Proper tension helps to ensure proper support and stability.

- Check the tightness of nuts securing the thimble eye bolts to prevent loose connections.

- Apply a suitable lubricant to the thimble eye bolts thread and moving parts. This is to prevent friction, corrosion and makes adjustments smoother.

- Replace the any thimble eye bolts that show signs of wear, deformation or damage that cannot reform through maintenance.

- Maintain detailed records of maintenance activities including inspection dates, adjustments made and the condition of the thimble eye bolts.

Comparative analysis of thimble eye bolts in South America

Conducting a comparative analysis includes evaluating different types of brands, types and designs. This helps to assess their strengths, weaknesses and suitability for specific applications. It also helps to identify the advantages and disadvantages depending on the application requirements. Additionally, it is advisable to consult with industry experts for guidance in selection. The following is a comparative analysis for thimble eye bolts in South America.

- Load capacity – compare the load capacities of different thimble eye bolts and select one that can handle the expected loads.

- Corrosion resistance – consider the level of corrosion resistance provided by each thimble eye bolt. Check for coatings such as galvanization and zinc.

- Installation ease – assess the ease of installation for each type of bolt and the tools required for installation.

- Brand reputation – consider the reputation of the brands who should have a track record of producing high quality products.

- Material – evaluate the materials used in the manufacture of the bolts such as stainless steel or galvanization options.

- Types and variations – compare the different types of the thimble eye bolt and consider the advantages and limitations.

- Costs – compare the prices of different bolts and assess their cost effectiveness based on factors such durability, load capacity and corrosion resistance.

Certifications and standards of thimble eye bolts

Thimble eye bolts must comply to various standards and certifications in south America. This helps to ensure the quality and performance of the bolt in various applications. Each south American country has their own set of regulations for use of the bolts. Also, it is advisable to consult with various regulators in the region for a better understanding of the market. The following are the common certifications and standards in south America.

- ASTM standards – this includes standards for a wide range of materials, products, systems and services. The thimble eye bolts must comply with the specific ASTM standards such as coatings.

- ASME standards – this develops standards for mechanical components and systems. This helps to ensure safety and performance of the applications.

- ISO certifications – this is a certification that ensures the product meets international standards for quality, safety and efficiency.

- IEC standards – these are standards for electrical and electronic products and systems including thimble eye bolt.

- ANSI standards – this is a standard for various products including bolts used in construction and utilities.

Regional market for thimble eye bolts in South America

There are various factors that influence the regional demand and supply for thimble eye bolts. Factors like manufacturers, suppliers and growth of the economy affects the regional market for thimble eye bolts. The following are the factors that influence the regional market in South America. The following are the factors that shape the regional market in South America.

- Renewable energy projects – the continued investments in renewable energy projects lead to increased demand for thimble eye bolts.

- Infrastructure development – expansion and upgrades in the electrical applications also influence the demand for thimble eye bolts.

- Innovation advancements – the innovative technologies help to advance the development of new designs and types for the bolts.

- Local manufacturing – the availability of local manufacturers and suppliers influence the demand of thimble eye bolts.

Frequently asked questions

A thimble eye bolt is a component used to connect cables, ropes or wires to a secure anchor point. It helps to protect the cable from wear, tear and prevents it from slipping or breaking.

The diverse environmental conditions in South America influences the choice for the thimble eye bolt. These factors include cost, material, adjustability, load capacity, ease of installation and compliance with standards.