In an electrical distribution system, drop wires or cables get support and security from drop wire clamp. They preserve the integrity and operation of the overhead transmission wires. This keeps the cables from sagging and guarantees that they have proper alignment. They support the drop wires that link to individual service points by splitting off from the main conductors. The clamps aid in stress distribution, damage prevention and transmission network dependability assurance. Drop wire clamps from robust materials like aluminum or galvanized steel. These materials resist environmental elements including weather, temperature changes and mechanical forces. They have movable parts that can adjust to suit various cable configurations and sizes. Among these elements are insulators which shield electrical connections between the clamp and the cable.

How to measure cable drop wire clamps

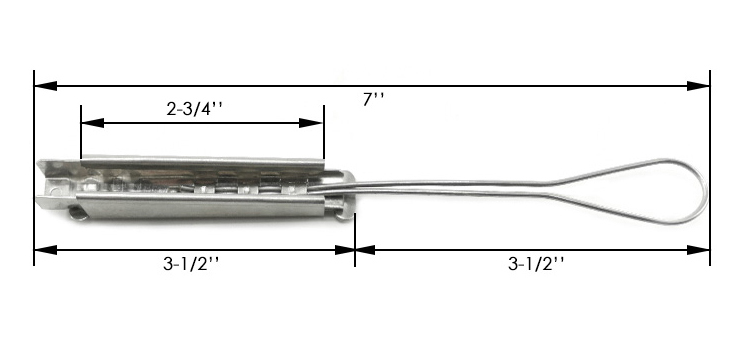

To guarantee correct sizing and cable compatibility, the clamps have many dimensions. Take into account elements including the cable’s diameter, the clamp’s size, adjustability, the load capacity, the need for insulation and the manufacturer’s recommendations. These elements aid in the measurement of drop wire clamps for cables and guarantee a suitable fit for your installation requirements. The procedures for measuring drop wire clamps and choosing drop wire clamps for cable sizes.

- Measure the diameter of the cable that the drop wire is to sustain. For an exact measurement, use a measuring tape or caliper. To choose a drop wire clamp that can accommodate the cable size, this is essential.

- Measure the width, length and height of the drop wire clamp when taking measurements of it. This makes it easier to make sure the clamp will fit inside the installation space and will support the cable enough.

- Examine the drop wire clamp’s load bearing capability to make sure it can support the expected load requirements. This will help to prevent the clamp from overstress.

- Verify the drop wire clamp’s insulation requirements by looking at things like voltage rating and insulation resistance.

- Determine the necessary clamp size by consulting the drop wire clamp manufacturer’s specs. This is to establish the cable diameter’s suggested size range.

The choice of clamps for drop wires

When selecting the best drop wire clamp, some criteria are necessary to take into account. This is to make sure it satisfies the intended needs. It is advisable to get advice and important insights from professionals in the business. When choosing a drop wire clamp, keep the following things in mind.

- Application – learn the drop wire clamp’s intended use. Think about whether it will function in fiber optic cables, overhead power lines, service drop connections or other applications. Certain clamp designs and features may be necessary for different applications.

- Conductor size and material – consider the dimensions and kind of the conductor that the clamp is to secure. Think about if the clamp is appropriate for the particular type of conductor. These comprise aluminum or copper, as well as the variety of sizes it can hold.

- Level of voltage – higher voltage lines could need extra-insulated clamps or clamps with a certain voltage rating. This is to guarantee safe and appropriate electrical operation.

- Mechanical strength – verify the clamp’s mechanical strength. It ought to be resilient enough to bear the weights and strain applied to the drop wire without breaking. Seek for clamps composed of robust, environmentally friendly materials that are resistant to corrosion.

- Installation specifications – specifications for installation as well as limitations on the power of the power transmission cables. Space that is available, mounting possibilities and hardware compatibility are a few of these.

- Standards of compliance – verify that the drop wire clamp satisfies all applicable industry requirements.

- Manufacturer reputation – take into account the manufacturer’s or supplier’s reputation. They must to have a history of manufacturing dependable, high-quality goods.

- Cost – before making a purchase, determine whether the drop wire clamp is cost-effective. You should also think about the clamp’s functionality, worth and durability.

Applications for drop wire clamps

Drop wire clamps are useful in a variety of industries, including power transmission. The uses differ based on local laws, industrial standards and power system needs. The application areas for drop wire clamps are as follows.

- Messenger wire suspension – the clamps assist in keeping the messenger wire at the appropriate height and orientation. This contributes to maintaining the integrity and stability of the electricity transmission networks.

- Service cables – clamps help to support drop wires used to connect service cables to buildings in service drop connections. They support preserving the appropriate tension of the drop wire and offer a dependable connection point.

- Temporary installations – construction and maintenance operations are examples of temporary installations for drop wire clamps. Drop wires can fasten to structures securely and quickly using temporary installations.

- Electrical cables – drop wire clamps work in conjunction with dead end fittings to secure overhead electrical cables. They aid in securing the conductors and stop movement or drooping brought on by ice, wind or other external conditions.

- Support for fiber optic cables – in communications, drop wire clamps also provide support for fiber optic cables. They give the cables a safe place to attach. This keeps the signal from drooping and ensures that it is properly sent.

Procedure for installing the drop wire clamp

During installation, secondary wires in transmission and distribution systems need to have strong support and consistent connectivity. The type of drop wire clamp, the wire’s diameter and the specific requirements of your electrical system all affect installation process. Here is a basic installation tutorial for drop wire clamps.

- Ensure that you have all the necessary protective gear, such as gloves, safety glasses and appropriate clothes.

- Gather all the equipment and materials needed for the installation. Secondary cables, drop wire clamps, suitable connections and fasteners are a few examples of these.

- Examine the hardware, cables, connectors and drop wire clamps for any defects or damage.

- Learn the drop wire clamp installations’ positions. Consider the mechanical aspects, secondary wire path and electrical system design.

- Use the right tools to access high places to ensure that the installation site is free of hazards and obstacles.

- After positioning the clamp in the desired location, make sure it has adequate room and is correctly aligned. Use the provided bolts to further fasten the clamp to the structure.

- Verify that the secondary wire positions within the drop wire clamp and in the middle. This is by putting it into the clamp’s gripping mechanism.

- Verify that the drop wire clamp’s insulating components position between the primary conductor and the secondary wire.

- Examine each drop wire clamp connection to ensure that it is firmly positioned and securely attached.

- Keep detailed records of the installation. This includes diagrams, blueprints and installation notes for each drop wire clamp.

The value of wire clamp application

When using drop wire clamps in overhead transmission lines, they are essential. They guarantee the lines’ safe and effective operation. To guarantee system stability and lower the possibility of service disruptions, the clamps also preserve the integrity of the cable. Make sure the clamps provide advantages tailored to your application’s requirements as well. The significance of employing drop wire is as follows:

- Preventing sagging – the clamps give cables the vital support they need to avoid drooping. This guarantees that the cable maintains the right tension and alignment for effective electrical transmission.

- Protection against damage – cables are vulnerable to mechanical, abrasive and wear damage. By fixing the cables into place, the clamps aid in preventing this kind of damage.

- Insulated drop wire clamp – the clamps avoid electrical contact between wires and other objects, thus improving safety. They make both the general public and maintenance staff safer.

- Easy maintenance – drop wire clamps make it possible to reach wires quickly and effectively. This is mainly when doing maintenance tasks. This lowers related expenses and downtime.

- Increased dependability – drop wire clamps help make the electrical distribution network more reliable. This is essential for satisfying customer requests and guaranteeing a steady supply of electricity.

- Increased stability – by adding stability, the clamps lower the possibility of cable movement. This lessens the possibility of infrastructure damage or service outages.

- Maintenance of clearance – the clamps keep the necessary space between cables and other objects. Interference and possible safety risks like electrical arcing are thus avoided as a result.

Frequently asked questions

A drop wire clamp is a hardware used to secure and support drop wires or cables. Its primary function is to prevent sagging and ensure proper alignment of the cables.

Drop wire clamps helps maintain cable integrity, ensuring system stability, preventing damage, enhancing safety, improve reliability and ease maintenance.

Common types of drop wire clamps include bolted, snap, suspension, adjustable, insulated, strain, parallel groove, hanger and corrosion-resistant clamp.

Drop wire clamps contribute to system reliability and safety by preventing sagging, ensuring stability, protecting against damage, maintaining clearance enhancing reliability and improving safety.