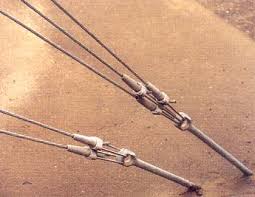

A strand vise is a device used to terminate and anchor guy wires in overhead transmission and distribution systems. It is also known as an automatic guy wire dead-end or an automatic guy grip. A automatic guy grip is securely grips and holds the guy wire while providing a reliable and adjustable point of attachment to the supporting structure. It consists of preformed, high-strength, galvanized steel grip that wraps around the guy wire. This allows for easy installation and maintenance of guy wires. The grippers allow even tension distribution across the wires. This is to prevent slippage and maintain a secure connection. They work in power transmission lines, telecommunication, guying masts, antennas among others.

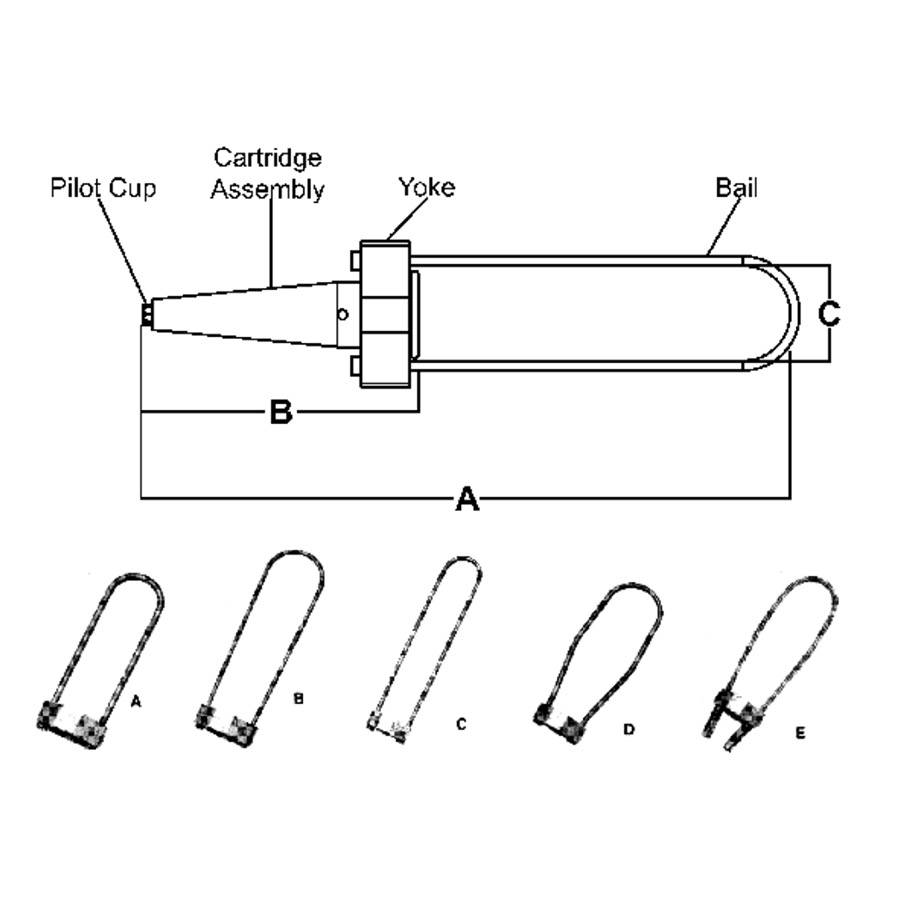

Components of strand vise

A strand vise involves several components working together to secure and terminate the guy wires in different installations. Different automatic guy grip may have different components that depend on various factors. These factors include the manufacturer and the specific requirements of the application. the following are the main components of the strand vise.

- Gripping elements – this is the main component of the automatic guy grip that holds the guy wire in place. It wraps around the guy wire and provide multiple points of contact to distribute the tension evenly.

- Thimble – this is a protective component used with the strand vise to prevent abrasion and damage to the guy wire.

- Outer housing – the housing cover encloses and protects the internal components against environmental factors.

- Fasteners – bolts, nuts or pins allow a reliable connection between the strand vise and the structure. This ensures proper anchoring and stability.

Types of an automatic guy grip

There are several types of strand vise available each with different designs and features. The specific type depends on factors such as application, required tensioning capabilities and manufacturer preferences. The following are the common types of strand vise.

- Hydraulic dead-end – these types use hydraulic pressure to secure and tension the guy wire. It allows for precise tensioning and adjustments as needed.

- Compression type dead end – this uses compression fittings to terminate the guy wire and provide effective tensioning.

- Wedge type dead end – these employ a wedge-shaped component that inserts in between the individual wires of the guy wire. This type is simple and effective than other types.

- Helical dead end – these types use a helical coil to provide automatic gripping and tensioning of the guy wire.

- Preformed automatic dead end – this consists of s preformed fitting attached to the end of the guy wire. It securely grips the individual wires of the guy wire thus providing a reliable termination point.

Applications of automatic guy grip

Strand vise find use in various applications in the power transmission industry. They mostly work in areas where the guy wire needs support. Strad vise provides secure termination, adjustable tension and automatic adjustment to changing conditions. These factors make them valuable components in various industries. The following are the common application areas of strand vise.

- Communication and broadcast towers – strand vise terminate and tension the guy wires. This ensures the towers remain securely anchored and aligned.

- Structural guying – strand vise work in applications such as bridges, large signs, tall buildings and other structures that need additional support against wind and lateral forces.

- Telecommunication towers – automatic guy grip help to anchor and tension guy wires used in towers. This is the ensure the stability and safety of the towers.

- Wind energy systems – strand vise ensure the safe and efficient operation of wind energy systems. This is by supporting guy wires used in wind turbines.

- Antenna mast guying – strand vise secures the guy wires and maintains the desired tension for proper functioning of the antennas or masts.

- Power transmission and distribution – strand vise secures and terminates guy wires used in utility poles, transmission towers and other structures.

How to install a strand vise

Installation process of the strand vise vary depending on the specific design and manufacturers instructions. Some manufacturers provide installation instructions during the process. Proper installation ensures the effectiveness and reliability of the guy wire system. This provides the necessary support and stability for the structure. The following is a basic installation guide for the automatic guy grip.

- Ensure the guy wire is properly measured, cut to the appropriate length and prepared for installation.

- Determine the desired location for the dead-end attachment on the structure. This ensures the attachment point is secure and appropriate for the load requirements.

- Attach the dead end depending on the type of dead-end. This may involve crimping a preformed fitting, compressing a compression-type fitting or wrapping a helical coil around the guy wire.

- Secure the dead-end to the structure using the provided attachment hardware such as bolts, nuts, pins or other fasteners.

- Tension the guy wire using appropriate tensioning methods and equipment. Follow recommended tensioning guidelines provided.

- Inspect the installation to ensure the guy wire is properly tensioned and aligned. Ensure the dead ends are in good condition after installation.

Factors to consider when selecting automatic guy grip

Selecting the best automatic guy grip involves considering several factors. This ensures the chosen dead end meets the specific requirements of the application. This is because the selected strand vise should meet the specific requirements of the intended application. Additionally, it is advisable to consult with industry experts, engineers or suppliers for specific guidance on the requirements of the application. The following are the factors to consider when selecting the best strand vise.

- Consider the diameter and type of the guy wire used to ensure the chosen dead end is compatible with the guy wire in terms of diameter, construction and design standards.

- Evaluate the automatic tensioning capability of the strand vise and ensure it can maintain the proper tension in the guy wire.

- Determine the maximum load the automatic guy grip needs to support by considering factors such as wind loads, ice loads and other environmental conditions.

- Consider the ease of installation and maintenance requirements and look for automatic guy grip that provides clear installation instructions and requires minimal maintenance.

- Assess the durability and corrosion resistance of the dead end and choose from high quality materials to withstand harsh environmental conditions.

- Ensure the selected automatic guy grip complies with relevant industry standards and regulations to ensure they meet the specific performance and safety requirements.

- Select automatic guy grip from manufacturers with a proven track record of producing high-quality products and providing excellent customer support.

Frequently asked questions

What is a strand vise as used in power systems?

A strand vise is a device used to anchor and terminate guy wires to ensure a reliable and adjustable point of attachment to the structure. It is also known as an automatic guy wire dead-end or an automatic guy grip.

What are the benefits of using strand vise?

The benefits of strand vise lie in their ease of installation, automatic tension adjustment, improved safety, enhanced stability, reduced maintenance and compliance with industry standards. These factors ensure the efficient and reliable guy wire systems in the industry.

What are the limitations of strand vise?

There are a number of limitations to consider when selecting strand vise for your application. these limitations include their complex installation, reliance on mechanisms, limited adjustability, maintenance costs, compatibility and initial costs.