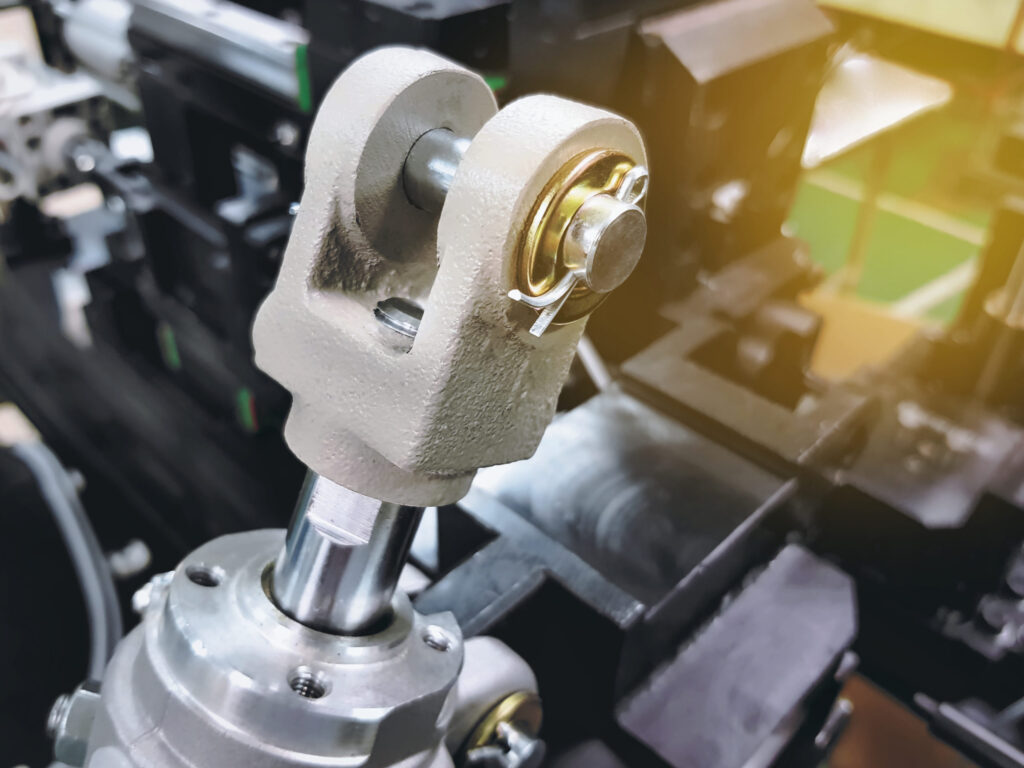

A socket clevis is also known as a socket tongue used to connect insulators and other line fittings to the power pole. It provides a strong and secure attachment point for the conductor or hardware. A socket tongue consists of a socket and a clevis pin that ease the installation on power transmission lines. It is from cast iron, steel or malleable iron. These materials helps them to withstand mechanical forces on the lines. They are also designed to provide reliable and durable connection and ensure the conductor do not slip off.

Components of socket clevis

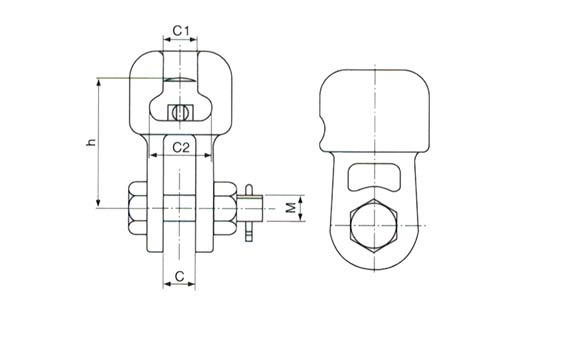

The socket tongue consists of two main components which allow for a reliable and adjustable connection between the power transmission line, insulator and pole. These components include the socket and the clevis. They ensure the stability, mechanical strength and proper functioning od the systems. The components are as detailed below.

- Socket – this is a cylindrical-shaped fitting with internal threads made from high-strength materials. It provides the connection point for the clevis pin to allow for change and tensioning. This also helps to prevent sagging and ensure proper line clearance.

- Clevis – this is a U-shaped metal bracket that inserts into the socket. It is from materials like steel and other strong materials. This provides a secure mounting point for the insulator and conductor. Additionally, the clevis consists of a clevis pin and a cotter pin which help to prevent loose connections.

Types of socket clevis

There are several types of socket clevis used on power transmission lines. different types of socket tongues are from different materials such as cast-iron socket iron and ductile socket tongue. Cast iron clevises work in general applications while ductile iron clevises work in applications with high risk of shock or vibration. The type of socket tongue selected depends on factors such as line configurations, required flexibility, tensioning requirements and environmental conditions. The following are the common types of socket clevis.

Straight socket clevis – this is the most used type of socket clevis which consists of a straight cylindrical socket and U-shaped clevis.

Ball-and-socket tongue – this socket includes a ball joint mechanism and has a matching rounded spherical shape. This design allows more flexibility and movement in different directions.

Tension socket tongue – this socket has additional features that ease tensioning and adjusting the power transmission line.

Swivel socket clevis – this socket has a design that facilitates the rotational movement at the connection point. This rotation helps hold line angles and reduce stress on the power transmission lines.

Angle socket clevis – these work in angled installations to provide the necessary alignment and support for the conductor and insulator.

Application areas of the socket tongue

Socket clevis play a vital role in the secure attachment, insulation and tensioning of power transmission lines. This is because they help to provide reliability, stability and efficient transmission of electrical power. The design and type of socket tongue used depends on the intended use, type and size of conductor and line configurations of the application. The following are the common areas of application for socket tongue.

- Overhead power lines – socket tongue hep to connect the tension clamp and insulator to the power poles in transmission lines. This connection provides electrical insulation and supports the conductor to ensure safe and efficient power transmission.

- Railways – socket tongue connect the catenary wires and the insulators in railway stations. This ensures the catenary wire is safe and secure.

- Tensioning and adjustment – some clevises with tensioning capacities help to adjust the tension in the power transmission lines. This helps to maintain proper sag and tension levels on the lines.

- Telecommunication – socket tongue work in telecommunication lines to ensure safe and secure connections. They help in angled connections and to increase flexibility and movement of other components on the lines.

- Lighting – socket clevises help in lighting constructions to ensure there are no loose connections.

Installation process of socket tongue on transmission poles

Installation process of socket tongues on power transmission lines depend on various factors such as equipment and manufacturer’s instructions. Additionally, it is advisable to consult with qualified professionals for guidance on the installation. This helps to know which socket tongue to use and the best fittings to work with. The following is a basic process of the installation.

- Prepare the work area and ensure it is clear of any debris and confirm all the necessary tools are available.

- Position the clevis at the desired location where the clevis will install and mark the drill holes on the pole or tower.

- Drill the holes using the suitable tools at the marked points on the pole. Make sure the holes match the diameter of the fasteners to use.

- Place the socket clevis back to the pole aligning with the drilled holes and insert the fasteners through the holes to tighten the clevis.

- Connect the insulator to the clevis end and ensure the insulator is properly aligned. The insulator should also be securely attached to the clevis.

- Insert the clevis pin through the hole of the insulator and into the socket of the clevis. The clevis pin should be fully inserted and properly aligned with the socket.

- Secure the cotter pin by inserting into the hole in the clevis pin and bend its end to prevent it from coming out.

- Visually inspect the installation to ensure all connections are secure and properly aligned.

Selecting the best socket clevis

Selection process of the best socket clevis is a tricky process as it should meet the specific requirements of the application. it should also ensure a secure and reliable connection for efficient power transmission. There are several factors to consider when selecting socket tongue. Additionally, you should consult with professionals in the industry for advice on the best clevis depending on your application. The following are the key factors to consider when selecting the socket tongue.

- Understand the specific requirements of the power transmission line by considering the voltage levels, conductor size and line configuration.

- Evaluate the environmental factors where the socket will install such as temperature variations, humidity and exposure to UV radiation. The selected socket tongue should be resistant to these conditions.

- Determine the expected load capacity on the socket tongue including tension, compression and bending forces. The selected clevis should safely handle the anticipated loads.

- Ensure the socket tongue is compatible with other overhead hardware such as insulators, conductors and pole attachments.

- The socket should conform to industry standards and regulations to help ensure safety, reliability and interoperability with other components.

- Select the socket tongue from reputable manufacturers who provide guidance on selecting the right socket tongue.

Frequently Asked Questions

What is a socket clevis as used on power transmission lines?

A socket clevis is a type of components used to connect the tension clamp and insulators to poles in the transmission systems. It helps provide a strong and secure attachment point for the conductor.

What are the main components of the socket clevis?

There are two main components of the socket clevis which include the socket and the clevis. It also has other features such as cotter pin, clevis pin and fasteners.

What are the benefits of using socket clevis?

Durable connections

Corrosion resistance

Safe and secure connections

Adjustability

Flexibility

Compatibility

Comply with industry standards

What are the limitations of socket clevis?

Limited movement

Specific thread compatibility

Installation complexity

Load limitations

Insulator compatibility

Tensioning limitations