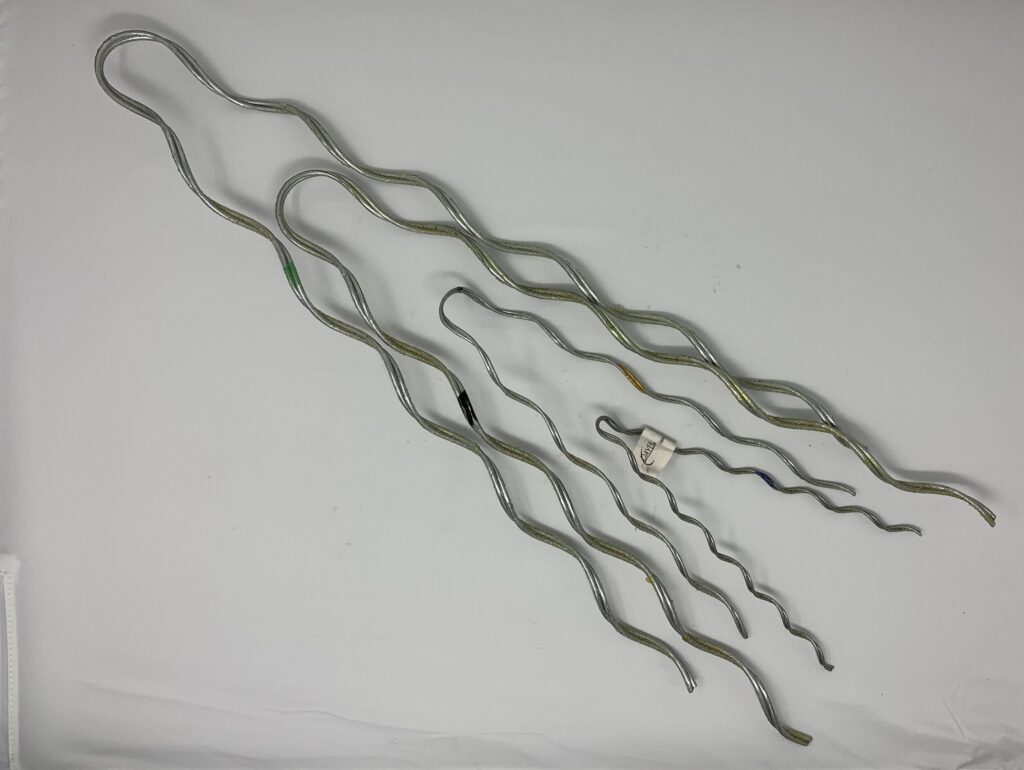

A service grip dead end is an essential component for the installation and maintenance of overhead transmission lines. It aids in the securement of conductor wires carrying electrical current, as well as other cables, at end points. A service grip dead end secures and terminates conductors on poles, towers, and other structures. It features designs that keep the conductor in place, preventing it from slipping or loosening with time. Its components include a loop end, materials, a helical structure, and materials for endurance. Using a service grip dead end ensures security, dependability, and simple installation. Materials used to make service grip dead ends include steel, aluminium, and composites. These materials are durable and resilient. They serve in applications such as overhead transmission lines, utility poles, and telecommunications.

Key characteristics of a service grip dead end:

A service grip dead end includes features that improve the dependability and safety of electrical distribution networks. Its design, material composition, and ease of installation all add to its effectiveness. The following are the main characteristics of the service grip dead end.

- Material compatibility – the grip is from materials that are compatible with the conductor. This helps to prevent galvanic corrosion. Common materials include aluminum, galvanized steel or aluminum-clad steel.

- High tensile strength – the dead ends have designs to handle high tensile loads. They help to ensure the conductors remain anchored. They also provide the necessary mechanical stability to maintain the integrity of the line.

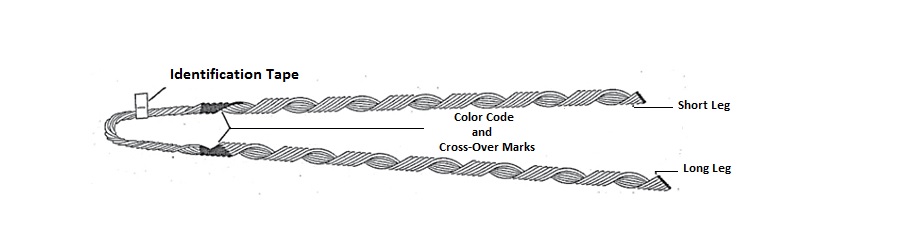

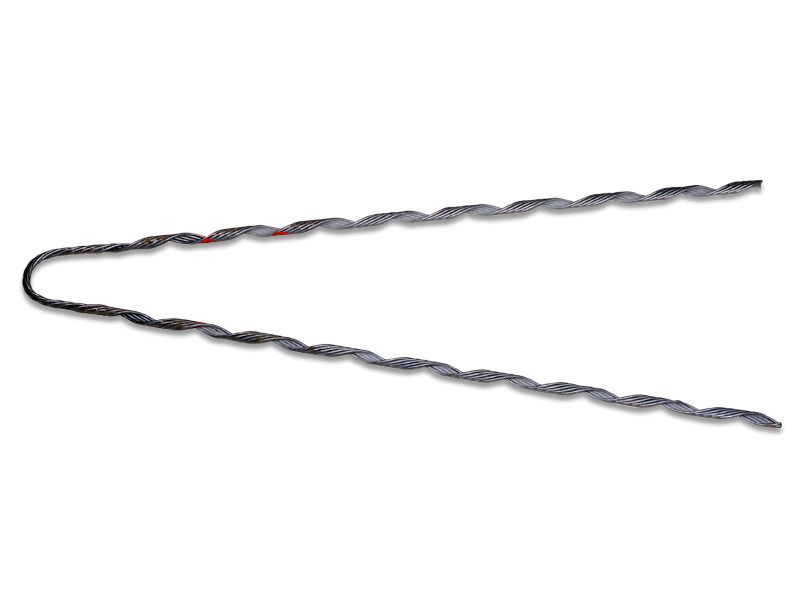

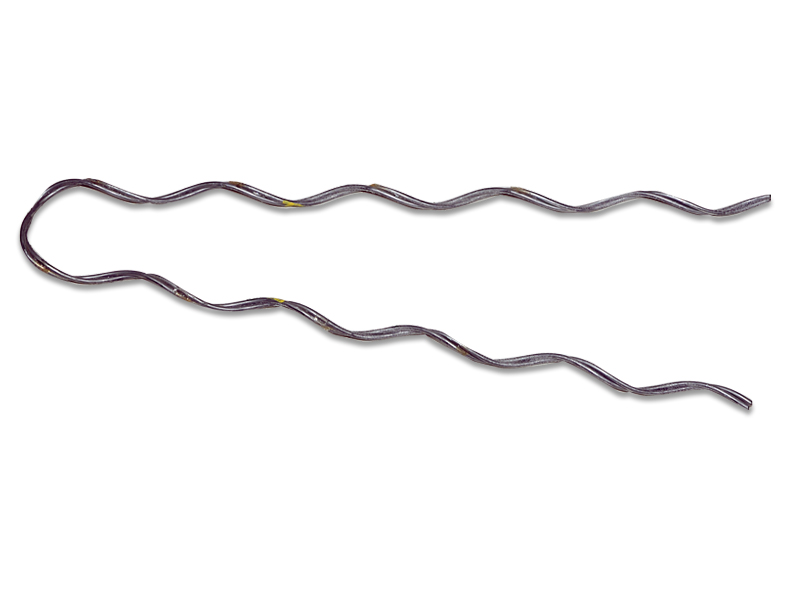

- Preformed helical structure – the dead end consists of a set of helical-wound preformed wires. The helical design also ensures the pressure distributes along the conductor.

- Ease of installation – the preformed nature of the grip allows for easy and quick installation. This is without the need for special tools or advanced skillset. This features reduces installation time and labor costs.

- Flexibility and adaptability – service grip dead ends are suitable for various conductor types. This versatility makes them applicable across different transmission line configurations.

- Reliable performance – the preformed design ensures a consistent and reliable grip on the conductor. The materials and design ensures performance reliability under a wide range of weather conditions.

- Safety features – the purpose of the dead ends is to terminate the conductor. The reliable anchoring by the grip helps prevent accidents related to failing conductors.

- Electrical conductivity – the grip dead ends have designs to provide good electrical conductivity. This ensures a reliable electrical path for grounding purposes to reduce electrical arcing.

- Minimal maintenance – the dead ends need minimal maintenance after installation. This is due to their strong construction which ensures long-term durability and stability.

The advantages of using a service grip dead end

Service grip dead ends have designs to perform many purposes in overhead transmission lines. Their primary responsibility is to anchor and terminate electrical conductors. They also ensure that power systems remain stable and reliable. They also help to ensure that transmission cables can deliver reliable power under a variety of scenarios. The following are the purposes of employing a service grip dead end.

- Tension management – they aid in managing and maintaining the proper tension of the conductors. The grip ensures the tension distributes along the conductor to reduce stress concentrations.

- Load bearing – the dead ends have designs to support the mechanical loads exerted by the conductors. This is including the weight of the conductors and extra loads from wind and thermal expansion.

- Secure termination of conductors – grip dead ends provide a secure termination point for conductors. This prevents the conductors from moving or slipping out of place. This is to maintain the integrity of the electrical networks.

- Vibration dampening – the helical design of the service grip dead ends aid in dampening vibrations. This reduces wear and tear on the conductors to prevent damage overtime.

- Ease of installation and maintenance – the design of the service grip dead ends allows for quick and easy installation. They also need minimal maintenance which lowers the maintenance costs and efforts.

- Enhanced electrical safety – the grip dead ends prevent accidental disconnections that could lead to power outages. A secure grip reduces the risk of electrical arcing at termination points.

- Line integrity maintenance – service grip dead ends ensure the continuity and integrity of the transmission line. This is by providing stable termination points for uninterrupted power supply.

- Cost efficiency – the ease of installation and minimal maintenance needs contribute to cost savings.

The most common types of service grip dead ends.

Service grip dead ends are available in a variety of forms and designs to meet specific application requirements and conductor types. These types contribute to the stability and reliability of the electrical infrastructure. Some of these types are easy to install and have high strength permanent terminations. Also, the choice of grip depends on by elements such as conductor type, load requirements, and climatic conditions. The following are the most frequent types of service grip dead ends used in overhead transmission lines.

- Automatic dead end grips – these use a self-activating clamping mechanism that grips the conductor. They also contain spring-loaded jaws or wedges that grip the conductor. They work in medium and high voltage transmission lines that need quick installation.

- Compression dead end grips – these grips use a sleeve compressed around the conductor using hydraulic tools. This provides a permanent, high strength termination for the conductor.

- Preformed dead end grips – these consist of helical-preformed wires that wrap around the conductor. They have designs to handle high mechanical loads and provide a strong grip on the conductor. Preformed dead end grips are suitable for terminating overhead conductors.

- Guy dead end grips – these have designs to terminate guy wires used for supporting structures like poles. They are suitable for telecommunications and utility structures to secure guy wires.

- Wedge dead end grips – these use a wedge driven into a housing to grip the conductor. It also has designs to handle high tension loads and provide a secure termination.

- Bolt-type dead end clamps – these uses bolts and clamps to secure the conductor to provide a mechanical hold. They are suitable for terminating both overhead and underground cables.

Applications of the grip dead ends

Service grip dead ends are components used in a variety of applications in the electrical transmission and distribution industry. They also work in environments that need dependable mechanical and electrical connections. They are adaptable and dependable, making them vital in maintaining stability. Before making a decision, it is also critical to understand how they work in different applications. The following are the most prevalent application areas for service grip dead ends.

- Distribution lines – service grip dead ends anchor conductors at various points along the distribution line. This includes at end poles and at points where the direction of the line changes. They work in pole termination, service drops and line changes.

- Telecommunications – the grip dead ends help to secure and end cables for telephone lines, internet cables and other lines. They ensure stable connections to reduce the risk of service interruptions.

- Overhead transmission lines – dead ends work in high-voltage and medium voltage transmission lines. They also provide a secure connection that ensures the stability and reliability of the transmission system. They help in conductor termination, tension management and line tensioning.

- Railway electrification – the dead ends work in electrification systems where they anchor and end overhead contact wires. They also help to end and tension contact wires that supply power to electric trains.

- Utility poles and structures – the dead end grips serve in securing and terminating cables and wires on utility poles. They are also versatile and allows for quick and reliable termination of cables.

- Guy wire applications – the dead ends help to secure and end guy wires that provide structural support to poles, or towers.

- Renewable energy installations – service grip dead ends help to secure and end cables that send power from generation sites to the grid.

Challenges and Issues with Service Grip Dead Ends

There are several problems and obstacles associated with using service grip dead ends. These factors can have an impact on the transmission lines’ reliability, safety, and efficiency. The following are the difficulties associated with using service grip dead ends.

- Material compatibility – using incompatible materials for the dead end and conductor can lead to galvanic corrosion.

- Environmental and weather impacts – the service grip dead ends may face ice loading and temperature fluctuations. This can lead to excessive tension and cause conductor slippage.

- Installation challenges – incorrect wrapping during installation can lead to ineffective gripping. This may lead to potential conductor slippage.

- Cost considerations – high quality dead ends can lead to the increase of the initial cost of transmission line construction.

- Electrical issues – this may include electrical arcing and grounding problems. They can lead to damage of the conductors and compromise their safety.

Frequently asked questions

High quality service grip dead ends provide reliable, secure and long lasting connections to reduce the risk of failure.

Service grip dead ends help to anchor conductors, manage tension, support mechanical loads and dampen vibrations.

Common challenges include incorrect installation, need for specialized tools and the need for skilled labor.