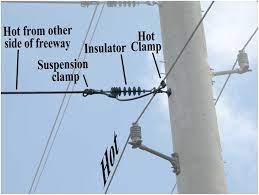

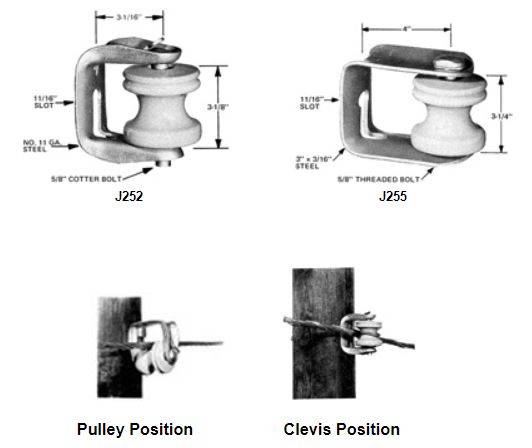

A secondary clevis is a component used to support and connect the insulators to the conductor to the line. It helps to maintain the integrity and proper functioning of the power transmission system. It is mostly a U-shape or Y-shaped metal bracket with holes. This helps to attach the various hardware components. Secondary clevis is from materials and coatings that resist corrosion. This makes them suitable for use in various weather conditions. Examples include ball and socket clevis, link-type, twist-on, pigtail and twin eye secondary clevis. Secondary clevises help to withstand the diverse environmental conditions of south America. These conditions include the humid amazon rainforests and arid expanses of the Andes. Secondary clevises find use in applications such as renewable energy projects, mountainous, coastal and rural electrification in south America.

Key features of secondary clevis

Secondary clevis has various features that help to provide secure attachment points. They help to ensure the secondary clevis is reliable and capable of supporting the integrity of overhead lines. The following are the key features of the secondary clevises.

- Durability – secondary clevis is from high strength materials that withstand the environmental challenges and mechanical stresses.

- Load capacity – they have designs that handle specific loads. This helps ensure they can support the weight and tension of conductors and insulators.

- Swivelling – an example like the ball and clevis allows for swivelling or rotation to reduce strain on insulators.

- Compatibility – the clevises work with other components such as crossarms, insulators and connectors.

- Temperature tolerance – the clevises can withstand a wide range of temperatures. This makes them suitable for use in diverse climates.

- Corrosion resistance – they are from materials that withstand corrosion in various environmental conditions.

- Secure attachment – they also provide reliable and secure means of connecting insulators, conductors and other hardware.

- Ease of installation – the clevises have user-friendly features for simple installations. This helps reduce labor costs and save time during installation.

- Adjustability – this allows for fine-tuning of the attachment position to enable precise alignment.

- Low maintenance – high quality clevises enable minimal maintenance. This helps to reduce the need for frequent inspections and replacements.

Selection and installation of secondary clevis

Proper selection of the secondary clevis helps to ensure the reliability and safety of lines. It consists of considering several factors including load capacity, environmental conditions, clevis type, size, compatibility and ease of installation. The installation should be from professionals to ensure the safety and reliability. The following is a general step by step installation guide for the secondary clevis.

- Preparation – gather all the required tools for the installation. This is including secondary clevises, insulators, conductors and safety equipment.

- Compatibility verification – confirm that the secondary clevis is compatible with other components.

- Pre-assessment – assess the secondary clevis for any visible defects, damage or irregularities. Ensure it is in good condition and free from any issues.

- Positioning – identify the exact location on the conductor where the secondary clevis will attach.

- Attachment – insert the suitable end of the secondary clevis through the insulator’s eye. Ensure it is in place and aligned according to the systems requirements.

- Tightening – use the suitable tools to secure the secondary clevis in place. Do this according to manufacturer’s recommended range.

- Alignment – confirm that the secondary clevis is properly aligned with the conductor and insulator.

- Swivelling – ensure there is proper adjustment to accommodate the deviations in the line.

- Inspection – perform final inspections to ensure the secondary clevis is securely attached and aligned correctly.

- Documentation – keep records od the secondary clevis installation. This is including the location, date and any specific details.

Maintenance and inspection of secondary clevis

Conducting maintenance and inspection of the secondary clevis helps to ensure the reliability and safety of overhead transmission lines. The various conditions in south America influence the frequency of this activity. It also helps to identify and address potential issues that may cause failures. Additionally, it is advisable to conduct professional maintenance and inspection of the clevises once in a while. The following is a basic guide for the inspection and maintenance of clevises in south America.

- Establish a routine for the inspection depending in the environmental conditions. It may be annually or semi-annually.

- Conduct ultrasonic tests to assess the integrity of the metal components in the secondary clevis.

- Conduct load tests to ensure the secondary clevis can safely support the expected loads on the transmission lines.

- Assess the condition of the insulators and conductors attached to the secondary clevis. Replace any damages or worn-out components.

- Check for sigs of wear, damage or corrosion on the secondary clevis. Apply anti corrosion coatings to the clevises to protect them from rust.

- Lubricate areas that has moving parts to ensure smooth operation and prevent corrosion.

- Ensure proper tightening of the fasteners and re-tighten the loose ones to prevent potential issues.

- Check the alignment of the insulators and conductors to prevent mechanical stress and ensure safety.

- Maintain detailed records of the inspections for future reference. Include any repairs or replacements made and any findings.

Comparative analysis of secondary clevis in South America

A comparative analysis includes evaluating various aspects of clevises in the market. These include features, applications, materials and manufacturers. The analysis helps to select the best secondary clevis for your application. Additionally, it is advisable to consult with industry professionals for guidance on the best clevis depending on your application. The following are the common factors to include in a comparative analysis in South America.

- Material – assess the materials used in the manufacture of the secondary clevis. The materials should withstand the diverse climates in South America.

- Compliance with standards – ensure the selected secondary clevises meet the relevant industry standards and regulations.

- Manufacturer reputation – research the reputation of the manufacturer who should have a track record for producing high quality products.

- Maintenance requirements – evaluate the maintenance needs of the different models. Select one that requires minimal maintenance to reduce operational costs.

- Type and features – compare the available types of secondary clevises available in the market. Evaluate their features including load capacities, swivelling and adjustability.

- Load capacity – compare the load bearing capacities of the clevises models and ensure they can support the anticipated loads.

- Ease of installation – evaluate how easy it is to install the selected secondary clevises.

- Cost effectiveness – compare the prices of the clevises and balance the quality and long-term reliability.

- Application areas – identify the secondary clevis type that best suits the specific application areas in South America. These include urban power distribution, rural electrification and coastal regions.

Certifications and standards in South America

Standards and certifications help to ensure the quality, safety and compliance with industry requirements. These standards provide guidelines for manufacturing, testing and performance of the components. These standards vary depending on each country in the region. Also, ensure the selected secondary clevis complies with all the relevant standards and certifications. The following are the standards and certifications in South America.

- ANSI standards – this provides requirements for the performance and testing of secondary clevises used in distribution lines.

- NEMA standards – this are standards for electrical equipment to ensure safe and reliable operation in various applications.

- IRAM – this is an Argentine organization that provides guidelines for secondary clevises and other equipment.

- ISO certification – this is a global certification that ensures quality to ensure the reliability of the products.

- ABNT – this is a standard applicable in Brazil for the secondary clevises used in electrical distribution.

Regional market for secondary clevis in South America

There are various factors that influence the regional market for secondary clevises in South America. These factors include the economic conditions, environmental challenges and infrastructure development. In addition, it is important for manufacturers and suppliers to observe the market trends and dynamics that influence use of secondary racks. The following are the factors that shape the regional market for secondary clevises.

- Geographic conditions – secondary clevises should withstand the various conditions in South America. This is including coastal areas, highlands, tropical regions and other environmental conditions.

- Renewable energy projects – construction of wind turbines and hydropower requires the use of secondary clevises.

- Local manufacturing and imports – availability of local manufacturers provide cost-effective solutions for secondary clevises.

- Economic factors – these influence the pace of infrastructure development and electrification projects. This in turn impacts the demand for secondary clevises.

- Innovation and technology – advancements in design and materials to improve performance, durability and ease of installation also impact the use of secondary clevises.

- Aging infrastructure – these require maintenance and upgrades that use secondary clevises.

- Rural electrification – expansion of electricity access to rural and remote areas requires the use of secondary clevises.

Frequently asked questions

A secondary clevis is a component used to connect insulators and conductors in overhead transmission lines. It helps to support and secure the components on the various South American transmission lines.

Secondary clevises find use in various applications in south American countries. These applications include urban power distribution, rural electrification, coastal regions and mountainous terrain.