A rock anchor is a component used to secure and support towers or poles installed in difficult terrain. It helps to ensure stability and safety of the transmission line infrastructure. A rock anchor mainly works in areas where traditional foundation methods are not practical. The rock anchor design helps to withstand geological and environmental conditions of the area. It also helps to ensure the safety and performance of the anchor. It is from materials such as steel and aluminum that offer durability. The deployment of rock anchors in Southeast Asia’s rough landscape greatly boosts the resilience of the electrical grid. Common types of rock anchors include grouted rock anchor, friction, bonded, threaded bar and tendon anchors. They find use in various applications such as transmission lines, slope stabilization, tunnel support, building foundation and geotechnical engineering.

Key features of rock anchor

The rock anchor has various features that help them improve safety and resilience of the transmission lines. The features depend on the type of application, environmental conditions and stability required. The following are the key features of the rock anchor.

- Load-bearing capacity – the anchor’s design help to withstand loads which makes them suitable for applications that need stability.

- Durable materials – they are from high-strength materials that resist corrosion and deterioration to ensure durability.

- Geological compatibility – the anchors are able to find use in different soil conditions in different environments. This may include hard rock, soft rock and soil.

- Ease of installation – the anchors are easy to install since they can install vertically, horizontally and a wide range of angles. This makes the installation easy and requires no special skills.

- Corrosion protection – the rock anchors may have corrosion-resistant coatings to extend their lifespan.

- Safety – the installations of the anchors should comply to safety protocols to protect workers during drilling, grouting and tensioning processes.

- Tensioning – the rock anchors offer tensioning to provide the necessary support and ensure a secure connection between the anchor and the structure.

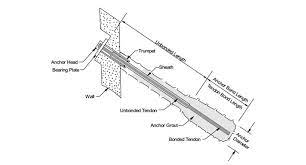

- Anchoring – the anchors use grounding mechanisms to secure themselves within the rock or soil. These mechanisms include mechanical expansion. Grouting, bonding or friction.

Selection and installation of rock anchor

The selected rock anchor should ensure they meet the geographical conditions and the intended purpose. The selection process involves careful consideration of various factors. These factors include load requirements, type of anchor, installation method, corrosion resistance, cost and site access. The installation involves several steps that ensure secure and safe connections in the rock. The following is a basic step by step process for the installation of rock anchors.

- Preparation – ensure all workers comply to safety standards such as wearing protective gear and equipment. Clear the work area of debris, vegetation or any other hinderance.

- Geological assessment – confirm the rock or soil condition and determine the ideal installation locations.

- Drilling – puncture holes into the rock or soil ensuring the diameter and depth of the holes match the anchor specifications.

- Cleaning – clean the holes drilled to ensure proper bonding and grout placement.

- Anchor placement – insert the anchor into the drilled hole using mechanisms such as mechanical expansion, grouted anchors or bonded anchors. This is depending on the type of anchor used.

- Grouting – inject the cement into the hole around the anchor to fill any voids if necessary. This helps to achieve a uniform grout placement on the installation.

- Tensioning – tension the anchor to the specified load capacity using hydraulic jacks or tensioning equipment.

- Curing – allow the grout to cure according to the manufacturer’s recommendations. This helps to ensure that the anchor becomes firmly bounded to the rock.

- Inspection – conduct visual inspections and tests to confirm the anchors installation integrity and load-bearing capacity.

- Documentation – keep detailed records of the installation process including drilling depths, torque values, grout volumes and other observations.

Maintenance and inspection of rock anchors

Proper maintenance and inspection of rock anchors help to ensure the continued safety and reliability of anchored structures. It also helps to identify potential issues early and help prevent failures and hazards. The frequency of maintenance depends on project requirements and environmental conditions. Additionally, it is advisable to seek professional help for guidance and expertise in the maintenance and inspection. The following is a basic guide for maintenance and inspection of rock anchors in Southeast Asia.

- Conduct visual inspections of the rock anchors to check for signs of damage, corrosion or wear. Also, check for loose anchor heads, nuts and plates.

- Examine the load indicators, if present, for any deviations from the specified load.

- Assess the elevation of the anchor heads to check for any changes. These changes could indicate movement or settlement.

- Perform load tests to confirm that the anchors meet the specified load-bearing capacity.

- Examine the anchor and its components for signs of corrosion to enhance its performance and durability.

- Inspect the grout condition and check for cracks, voids or signs of deterioration. Ensure it is well bonded to the surrounding rock,

- Clean to remove dirt, debris or vegetation accumulated around the anchor heads or plates.

- Apply lubrication to moving parts to prevent corrosion and ensure proper functioning of the components.

- Repair or replace any damaged anchor components following proper procedures based on the type or rock anchors.

Comparative analysis of rock anchor in Southeast Asia

A comparative analysis involves assessing and evaluating different types, designs and cost of rock anchors. Additionally, it is advisable to consult with industry professionals for guidance on selection and use of the rock anchors. The selected rock anchor should meet the specific weather and soil conditions in Southeast Asia. The following are the common factors to include in a comparative analysis for rock anchors.

- Load capacity – the rock anchor should be able to provide high load capacity especially when grouted for heavy-duty application.

- Type of application – they should be able to offer proper performance and stability to various applications. These include transmission lines, bridges, dams, slopes, tunnels, building foundations and soil nailing.

- Ease of installation – the rock anchor should offer ease of installation using various mechanisms. Some may require adhesive injection, drilling, grouting or expansion mechanism.

- Geological compatibility – the selected rock anchor should be able to work in various soil conditions in Southeast Asia. These may include soft or rocky soils in the diverse geological conditions.

- Type of rock anchor – the type of rock also influences the selection process. Common types include grouted rock anchors, friction rock anchors, bonded anchors, tendon anchors and soil nails.

Certifications and standards in Southeast Asia

There are several standards and regulations for rock anchors in Southeast Asia. These standards and certifications govern the use and applications of rock anchors for particular applications in the industry. They help ensure the anchors properly install and designed to improve safety and efficiency. Some of the standards in Southeast Asia take after the international standards for rock anchors. These standards vary by country in the diverse region of Southeast Asia. The following are the common standards and certifications for rock anchors in Southeast Asia.

- International society for rock mechanics (ISRM) – the document provides an overview of rock anchors testing methods. This also includes installation, testing and evaluation.

- ASTM standards – this provides specifications for the design, manufacture and testing of rock anchors.

- British standards institution – this is a code for practice that provides guidance on design installation and testing of the anchors.

- Building and construction authority (BCA) – these are standards and regulations for the construction industry concerning rock anchors.

- Department of highways – in Thailand, these are standards for highway construction specifically for rock anchors. Certifications are from government agencies or project owners.

- The Malaysian public works department provides guidelines and standards for civil engineering projects.

Regional market for rock anchors in Southeast Asia

There are various factors that influence the regional market and demand of rock anchors in Southeast Asia. The specific market conditions may vary depending on one country to another. Additionally, it is advisable for market players to consider local factors and industry trends for success in the market. The following are the key features that shape the regional market for rock anchors in Southeast Asia.

- Construction industry growth – the rapid urbanization, population growth and economic development fuels demand for rock anchors.

- Geotechnical challenges – the region experiences diverse geological conditions that influence the demand of rock anchors. These include rocky soils and soft soils in different mountainous regions.

- Energy sector – development of hydropower and renewable energy relies on rock anchors for dam construction and anchoring wind turbines.

- Mining – mining operations require rock anchors for slope stabilization, tunnel support and securing equipment.

- International standards – most of the countries align with international construction standards such as ASTM, ISO and other global standards.

Frequently asked questions

What is a rock anchor and its importance in Southeast Asia?

Rock anchors are components used to stabilize structures in challenging geological and soil conditions. They help to offer stability to the diverse terrains of Southeast Asia such as rocky areas, slopes and coastal regions.

What are the key factors to consider when selecting rock anchors for use in Southeast Asian projects?

It is important to consider geological conditions, load-bearing requirements, installation methods, environmental considerations and compliance with local standards.