A post insulator is a component designed to provide electrical insulation and mechanical support. It works in different configurations and for different purposes. They work in installations like switchyards, substations or power distribution systems. Post insulators should have high dielectric strength to withstand the voltage levels present. This is without causng electrical breakdown. Its design depends on factors such as voltage rating, environmental conditions and mechanical needs. Common design includes solid core, hollow core and composite insulators. Post insulators are from materials such as polymer, glass or polymer materials. This is due to their mechanical strength and resistance to environmental degradation. They provide electrical insulation between the conductive equipment and the support structures.

Benefits of using a post insulator

Post insulators offers several benefits contributing to reliability, safety and efficiency of the electrical system. This helps make them crucial components in all electrical installations. The various benefits are as discussed below.

- Electrical insulation – post insulators provide insulation between conductive components and support structures. This prevents the current leakage and ensures safe operation by reducing the risk of electrical faults.

- Voltage insulation – the insulators prevent electrical breakdown and flashovers in high-voltage installations.

- Corrosion resistance – post insulators are from materials like porcelain, glass or polymer composites. They are resistant to corrosion, rust and chemical degradation to ensure durability and extend the service life.

- Lightweight construction – some of the insulators are lightweight which reduces the load on support structures. The design reduces transportation costs and makes handling easier.

- Versatility – post insulators are available in various types, sizes and configurations. This is to suit different applications. This allows for flexibility in design and ensures compatibility with diverse electrical systems.

- Mechanical support – they also offer stability and support to heavy electrical equipment. They help withstand mechanical stresses, vibrations and impacts to ensure the integrity of the equipment.

- Weather resistance – they have designs to withstand harsh environmental conditions. This is including moisture, UV radiation, pollution and temperature fluctuations.

- Damage resistance – exposure to vandalism in outdoor installations may lead to damage of the insulators. Composite post insulators are from durable and non-conductive materials resistant to damage.

- Ease of installation – the insulators have designs that allow easy installation onto support structures. This is by use of suitable fittings and mounting hardware provided for secure attachment.

Accessories used with post insulator

There are various components used with post insulators that help ensure proper installation and functionality. Use of these fittings helps to ensure proper functions, durability and reliability. The following are the common accessories used with post insulators in electrical installations.

- End fittings – these are accessories used to mount post insulators onto support structures. They provide a secure attachment point for the insulator and ease the connection to the conductor.

- Fittings for line attachment – fittings help to attach the conductor to the post insulator. They include ball and socket, clevis-type or other fittings designed to allow flexibility and movement.

- Spacer devices – these work between many post insulators to maintain proper spacing and alignment along the line. They help prevent electrical arcing, corona discharge or flashovers between adjacent insulators.

- Insulator cleaning equipment – this includes brushes or washers used to remove dirt, dust or pollution. Cleaning help to maintain proper electrical insulation and reduce the risk of flashovers.

- Metal hardware – these include components such as bolts, nuts, washers and clamps. They help to secure post insulators to supporting structures and provide mechanical stability.

- Grounding devices – these include grounding rods or straps used to ensure proper grounding of the electrical system. They also help to protect against electrical faults and dissipate excess electrical energy to the ground.

- Insulator covers – these are protective devices used to shield post insulators from environmental factors. The factors include moisture, UV radiation, pollution or physical damage.

- Grading rings – these work on high voltage post insulators to control corona discharge and reduce the risk of power loss. They help to distribute the electric field along the insulator surface. They also reduce the occurrence of corona-induced problems.

Performance characteristics of post insulators

There are various ways to check the performance of post insulators in electrical installations. These characteristics help to ensure the reliability, safety and efficiency of electrical systems. The following are the common performance characteristics of post insulators.

- Dielectric strength – this is the greatest voltage that an insulator can withstand without breakdown. High dielectric strength helps to ensure the safe operation of electrical systems.

- Pollution performance – the insulators should resist the accumulation of pollution on their surface. This helps to maintain electrical insulation.

- Mechanical strength – this helps to withstand stresses induced by wind, ice and vibration. Performance depends on tensile strength, compressive strength and resistance to mechanical impact.

- Creepage distance – adequate creepage distance helps to prevent flashovers caused by pollution, contamination or moisture.

- Electrical insulation – this is the main purpose of the insulators in electrical installations. Performance depends on the insulator’s ability to withstand high voltage levels without electrical breakdown.

- Weather resistance – the insulators should be resistant to environmental factors. This is including UV radiation, moisture and pollution. It should ensure long term reliability and performance in outdoor installations.

- Frequency response – the insulators should show consistent performance across a range of frequencies. This is especially in applications such as radio communication or railway electrification systems.

- Corrosion resistance – materials such as porcelain, glass or polymer composites provide resistance to corrosion and rust.

Cost comparisons and considerations when selecting post insulators

There are several suppliers and manufacturers in the industry selling post insulators. It is important to consider several factors that influence the price of the insulator. Additionally, it is advisable to consult with different suppliers for quotes to compare the prices. Evaluating these factors helps determine the most cost-effective solution for the application needs. The following are the factors to consider when checking the prices for post insulators.

- Material cost – porcelain and glass insulators are cheaper for low to medium voltage applications. Composite insulators may have a higher initial cost due to their advanced materials.

- Maintenance costs – consider the maintenance needs and related costs for the post insulator. Composite insulators may need periodic cleaning or inspection which leads to maintenance costs.

- Voltage rating – higher voltage applications need larger and more strong insulators. This may lead to an increase in price compared to lower voltage applications.

- Supplier and quality – the supplier should have a track record for producing quality products. Higher quality insulators may have a higher upfront cost but offer better performance.

- Total cost of ownership – this includes the initial purchase price, installation costs, maintenance expenses and potential replacement costs. The total cost of ownership can help check the most cost-effective option in the long run.

- Installation costs – lightweight insulators are easy to install which may need less labor and time for installation. This is as compared to heavier materials such as porcelain or glass.

- Environmental conditions – consider the environmental conditions in the insulator installation area. Composite insulators offer better resistance and longevity which reduces maintenance and replacement costs.

- Insulator design and configuration – these may include solid core, hollow core or long-rod insulators. Some of the designs may come with extra costs compared to standard options.

Supplier and vendor information for post insulators

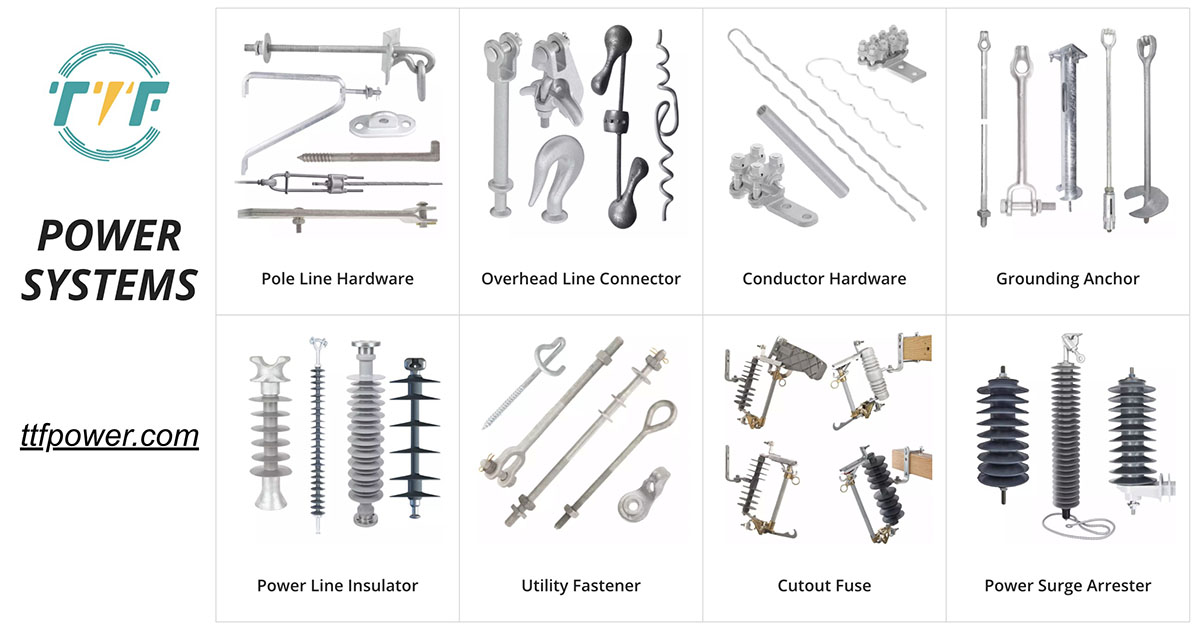

There are several reputable suppliers and vendors of post insulators that offer a wide range of products. It is important to consider several factors that influence the product quality and price. Additionally, it is advisable to conduct research and check different options that can help ensure the best choice. Common suppliers include TTF Power Systems based in China. They offer a wide range of quality insulators among other products. The following are the common factors to consider when selecting a supplier for post insulator.

- Product quality – check the quality of the supplier’s products. This is by checking for certifications, standard compliance and track record of delivering quality products.

- Experience and expertise – check the supplier’s experience and expertise in the industry. Check for suppliers with a deep understanding of your specific needs and challenges.

- Cost and pricing – compare pricing structures and total costs from various suppliers. Consider factors such as volume discounts, payment terms and value for money.

- Customer service and support – select a supplier that provides customer service and support. Consider responsiveness, communication and after-sales support.

- Supplier stability and sustainability – assess the financial stability and health of the supplier. Look for indicators such as financial statements, credit ratings and long-term viability.

- Location and logistics – consider the supplier’s location and logistics capabilities. This is considering requirements for shipping, storage and international transactions.

- Capacity and scalability – ensure the supplier has the capacity and scalability to meet project needs.

Frequently asked questions

Post insulators are components used to provide electrical insulation and mechanical support in electrical installations. They prevent current leakage to ensure safe transmission of electricity by insulating conductors.

The insulators offer benefits such as electrical insulation, mechanical support, weather resistance, ease of installation and durability.

Check the certifications, customer requirements and industry standards. Conduct research, request samples and check references and reviews on quality and reliability.