A hot line clamp is a tool specialized by electrical workers to perform maintenance and repair work on live electrical power lines. It is also known as a live line clamp or a live line tool. Live line clamp provides a safe and secure connection to the power line and minimizes the risk of electric shock or injury to the worker. It is from high-strength metal alloy such as bronze or brass. A hot line clamp has insulated gripping surfaces that prevents the electricians from touching live wire. It can make a tap connection, make temporary connection and make a permanent connection. Working on live power lines is dangerous and only professionals should handle them.

Components of the live line clamp

There are various components of the live line clamp working together to enhance the safety and security of the overhead transmission lines. The available components vary depending on the voltage levels and safety regulations. The following are the main components of the live line clamps.

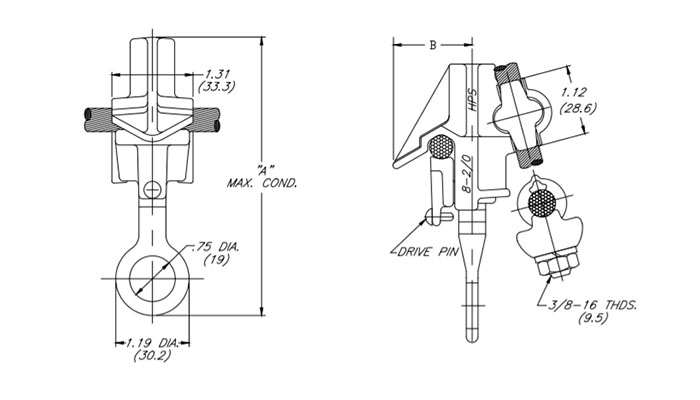

- Clamp body – the body is the main component of the clamp made of high-strength metal alloy. It has two gripping surfaces on each side to prevent the electrician from touching the live wire.

- Keeper – this is a metal piece attached to the body of the hot line clamp to secure the clamp to the wire.

- Eye bolt – this is a metal rod that attaches to the body of the live line clamp to secure the clamp to a pole.

- Spring – this is a metal piece attached to the body of the clamp to help keep the clamp closed.

Types of live line clamp

The type of hotline clamp selected depends on factors such as voltage of the line, size of the wire and the environment in which the clamp will install. The high voltage hot line clamp should ensure safety of the workers and the reliability of the electrical system. The most common types of hot line clamps are as follows.

Compression clamps – these are the most popular types of hot line clamp. The clamps are easy to use and difficult to remove. hot line clamps use a compression force which ensures a tight and reliable connection. They work for medium to high voltage applications.

C-type hot clamp – these clamps have a C-shaped configuration that allow them to easily attach and detach from the conductors. They are mostly used in lower voltage applications using a locking mechanism to secure the clamp.

Bolted type hot line clamp – this type uses bolts and nuts to secure the clamping jaws around the conductor. They provide a sturdy and reliable connection needed for high voltage applications.

Tap clamps – these types help to make a tap connection to a live electrical line and add a new line to the existing line.

Application areas of the hot line clamps

Hot line clamps have various applications areas in electrical power systems and maintenance. They can work to make a variety of connections to live electrical lines to save time, money and safety. The application areas of the hot line clamps are specific to qualified and trained electrical workers. The following are the man application areas of the hot line clamps.

Live line maintenance – live line clamps work in live line maintenance activities on electrical power lines. They allow the electrical workers to safely access live conductors without disruption of the power supply.

Distribution line work – the clamps help in distribution line maintenance and repair. It also enables the workers to work on live conductors, perform reconfiguration and repair faults in distribution lines.

Troubleshooting and fault detection – the clamps help during troubleshooting to separate and identify faulty sections of power lines.

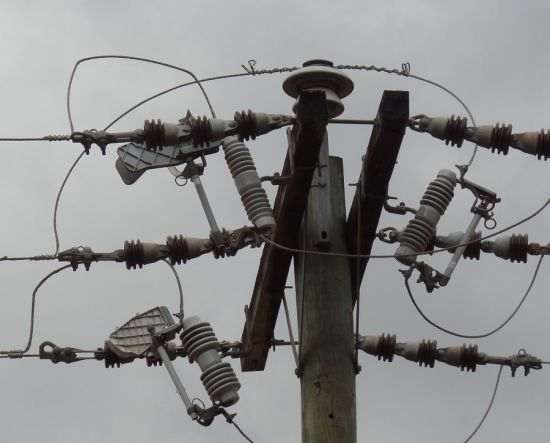

Transmission line work – maintenance and repair of overhead transmission lines use hot line clamps. They enable workers to safely perform tasks on live conductors.

Substation maintenance – live line clamps help to safely handle and manipulate live conductors within the substation. This allows tasks such as installing or removing circuit breakers and maintaining switchgears.

Line inspection and survey – the clamps allow the workers to navigate power lines while maintaining a secure connection. This enables them to visually inspect and assess the condition of conductors, insulators, hardware and other components.

Installation process of the hot line clamp

High voltage live line clamp undergoes a series of processes during the installation process. As already discussed, the clamps are hazardous as they operate on live lines. for this reason, it is advisable to leave the installation process to the professionals and trained experts. The following are the basic steps to install the live line clamp.

- Ensure you follow the safety precautions before beginning work on power lines. Wear personal protective equipment and ensure proper training.

- Clear the work of any probable hazards and ensure the power line is properly de-energized.

- Select the appropriate hot line clamp for the specific conductor size, voltage level and application requirements. Ensure the clamp is in proper working condition and inspect for visible damage or defects.

- Position the clamp grips around the conductor at the desired location. Ensure the clamping mechanism is in the open position to allow easy attachment.

- Secure the clamp using the necessary mechanisms following the manufacturer’s instructions for proper engagement.

- Confirm that the clamp is secure and attached to the conductor to ensure a reliable connection.

- Conduct the necessary tests and inspections to verify the integrity of the installation. This includes checking for proper voltage indicators and ensuring the clamp is electrically insulated and stable.

- Document the installation including details such as date, location and clamp type for future reference.

Selection process of the live line clamps

There are various types and designs of the hot line clamp in the market with different pros and cons. The selection process should thus consider factors that help to choose the best clamp. It should meet the specific requirements of the project. Additionally, it is advisable to consult with professionals in the electrical industry for advice in the best clamp for your application. The following are the key factors to consider when selecting the best live line clamp.

- Regulate the voltage level of the power line on which the clamp will attach. Ensure the clamp can safely handle the electrical stress on the voltage levels.

- Consider the size and diameter of the conductors on the power line which should house the specific conductor size.

- Evaluate the environmental conditions around the installation area. Examine factors such as temperature extremes, moisture, UV exposure and chemical exposure.

- Consider safety feature available in the clamp which includes voltage detectors, grounding capabilities, insulation properties and regulations.

- Ensure that the clamp complies with relevant industry standards, regulations and safety guidelines.

- Consider the manufacturer’s reputation who should have a record of producing high-quality products.

- Evaluate the cost and value of the hot line clamp including its features, quality and performance. Consider durability, longevity and level of protection it offers.

Frequently Asked Questions

What is a hot line clamp as used on power transmission lines?

A hot line clamp is a device used to make a connection to a live electrical line. It has insulated gripping surfaces to prevent electrocution.

What are the safety precautions to take when using hot line clamps?

Always wear safety glasses and gloves

Ensure power is off

Use the correct live line clamp

Do not over tighten the clamp

What are the benefits of using a hot line clamp?

Enhanced safety

Live line maintenance

Time and cost efficiency

Secure connection

Training and skill development

Compliance with standards

What are the limitations of the hot line clamps?

Conductor size limitations

Voltage limitations

Affected by environmental conditions

Improved mechanical strength

Operator skill and training

Limitations of insulation