Overhead line hardware are components used in the construction of overhead transmission lines. They are also known as overhead line accessories or overhead line fittings. The components ensure the reliability, safety and efficient operations of electrical power lines. This is from power generation sources like power plants to substations and consumers. Overhead line fittings are from materials such as steel, aluminum and galvanized steel. They help to withstand environmental conditions, mechanical stresses and electrical requirements. Overhead line fittings work in applications such as conductor support, vibration dampening, maintenance and inspection.

Components of overhead line accessories

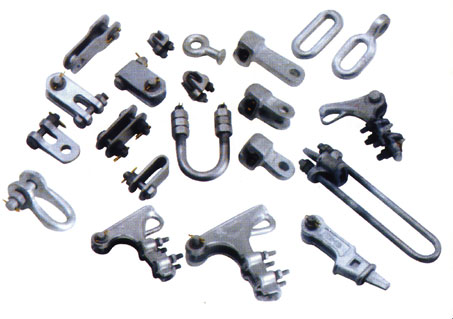

There are various components that work together to support, insulate and secure the conductors. The various components ensure the safe and efficient transmission of electrical power. Selection of these components vary depending on various factors. They include type of transmission line, voltage level, environmental conditions and load requirements. The following are the main components of overhead line hardware.

- Insulators – insulators help to support the conductors while preventing the flow of electricity to the supporting structures.

- Spacers – these maintain the separation between multiple conductors on the same transmission line. They prevent contact and arcing between adjacent conductors.

- Dead-end hardware – these include devices such as guy wires, thimbles and guy grips. They help to anchor the ends of conductors securely to transmission towers.

- Clamps and connectors – they secure conductors to insulators or other hardware components. This helps to provide mechanical stability and maintain the proper positioning of the conductors.

- Crossarms and brackets – these attach to the transmission towers to provide a structure to hold insulators.

- Tension hardware – these include tension clamps, tension insulators and suspension sets. They aid in maintaining the proper tension in the conductors to prevent sagging.

- Line hardware – this refers to various components used to assemble and support the conductors such as bolts, nuts and washers.

- Vibration dampers – these attach to the conductors to reduce vibrations. Less vibrations reduce the risk of conductor fatigue and damage.

Types of overhead line fittings

There are various types of overhead line fittings used to support, insulate and secure transmission lines. These types are mostly designed to withstand various environmental conditions and mechanical stresses. This ensures the safe and reliable operation of overhead transmission and distributions lines. Galvanized steel crossarms are commonly used in transmission towers across southeast Asia. This is to ensure the stability of overhead power lines against strong tropical winds. The following are the common types of overhead line fittings.

- Suspension clamps – these clamps suspend conductors from the poles to reduce the risk of damage and fatigue

- Dead-end clamps – these clamps secure the conductors to the poles and prevent them from moving.

- Insulators – these prevent the conductors from touching which might cause short circuits.

- Crossarms – these support the insulators and conductors on the overhead transmission lines.

- Tension hardware – these help to maintain the tension in the conductors and prevent sagging.

- Splicing clamps – these clamps help to join two conductors together.

- Armor rods – the rods help to protect the conductor from abrasion and damage at points where it passes through fittings.

- Guy wires – guy wires provide extra support and stability to transmission towers.

Application areas of overhead hardware

Overhead line fittings find use in various applications in the industry. These includes construction, operation and maintenance of transmission lines. They help to ensure reliability, safety and efficiency of electrical power transmission. The following are the common application areas of overhead line fittings.

- Conductor support and insulation – overhead line fittings help to support the conductors while preventing electrical current from flowing to the supporting structures.

- Mechanical stability – these fittings provide mechanical stability to the conductors. They also help maintain their proper positioning.

- Electrical performance – these designed fittings ensure the conductors space out correctly. This is to avoid electrical interference and arcing between them.

- Vibration dampening – the dampers reduce the vibrations caused by wind. This prevents fatigue and mechanical damage to the conductors.

- Grounding – grounding equipment help to ensure that electrical currents safely dissipates to the ground. This helps to protect both the equipment and personnel from electrical hazards.

- Wildlife and vegetation protection – In countries like Indonesia and Malaysia with diverse wildlife, line guards help to safeguard overhead conductors from animal interference.

- Maintenance and inspection – insulators and other fittings help with regular maintenance and inspection activities.

- Structural integrity – these fittings provide the necessary support for insulators and conductors. They also help distribute mechanical loads across the transmission towers.

Installation guide for overhead line fittings

Overhead line fittings require proper planning and adherence to safety standards. This is to ensure reliability and longevity of the transmission and distribution lines. The process varies depending on the type of hardware, specific transmission line designs and regional regulations. Additionally, it is advisable to consult with industry experts to ensure a successful and safe outcome. Proper installation techniques for tension hardware are crucial in countries like Thailand and Vietnam. This is because the countries have fluctuating weather patterns. These weather conditions exert varying loads in overhead conductors. The installation process is as discussed below.

- Plan the installation sequence taking into account factors such as the type of hardware, environmental conditions and accessibility to installation sites.

- Identify and assess potential hazards at the installation site. These may include power lines, environmental conditions and uneven terrain.

- Ensure that the transmission towers are structurally sound and capable of supporting the extra hardware.

- Inspect the components before installation to ensure they are free from defects, damage or corrosion.

- Install the specific components following the manufacturer’s guidelines for proper installation techniques.

- Conduct inspections of the installed hardware after installation. This is to ensure proper alignment, connection integrity and adherence to design specifications.

- Keep detailed records of the installation process. This includes hardware used, torque values and any deviations from the original plan.

Selecting the best overhead line accessories

Choosing the right hardware ensures safety and protect personnel from electrical hazards. The chosen components should meet the requirements of the specific transmission project. There are several factors to consider like technical specifications, safety standards, and reliability. In coastal regions like Philippines and Singapore, selecting corrosion-resistant tension hardware ensures the longevity of the systems. The following are the common factors to consider when selecting the overhead line hardware.

- Understand the design specifications and requirements of the transmission or distribution line.

- Determine the expected mechanical loads and tensions that the hardware will withstand.

- Consider the environmental conditions of the region. Check factors like salt exposure, humidity or pollution.

- Choose hardware made from materials that offer mechanical strength, electrical insulation and durability.

- Ensure the selected components are compatible with each other and with other line infrastructure.

- Select insulators designed to handle the voltage levels of the transmission lines.

- Ensure that the components comply with relevant safety standards and regulations.

- Select fittings from reputable manufacturers known for producing high quality products.

- Consider the ease of installation and future maintenance requirements to reduce downtime and operational costs.

- Consider the cost effectiveness of the hardware and balance the quality with the budget constraints.

Frequently asked questions

What are overhead line fittings?

These are components used in the construction and maintenance of overhead transmission and distribution lines. They ensure reliability, safety and efficient operations of the electrical power lines that transmit electricity over long distances.

What are the advantages of using overhead line fittings?

Overhead line fittings offer various benefits that contribute to efficient, reliable and safe operation of the transmission lines. These benefits include reliability, safety, mechanical stability, longer service life, reduced vibrations, wildlife protection, visual enhancement, ease of installation and cost effectiveness.

What are the limitations of overhead line fittings?

The fittings are available in different designs and configurations which affect their efficiency. The various limitations include corrosion, installation complexity, aging infrastructure, mechanical failures, conductor sag, visual impact, cost, voltage limitations and compatibility issues. Consider these factors before selecting the overhead components for your applications.