A ball clevis is a mechanical component used for connecting different hardware elements in the construction of overhead lines. It is also known as a clevis eye that connects the insulator by its ball head. The clevis also attaches the conductor to the other hardware devices such as insulators and suspension clamps. Additionally, the clevis eye is available in different sizes and materials and the size is dependent on the weight of the load it will be carrying. In overall, clevis enables the overhead components to withstand external forces and environmental conditions.

Components of a clevis eye

Different components of the clevis eye work together to provide secure and reliable connections. Durable clevis is from corrosion resistant materials such as steel and galvanized coating. The following are the main components of a clevis eye.

- Body – this is a metal component that makes up the main part of the clevis eye with a resonating socket or loop at one end to house the conductor and other devices.

- Ball socket – this is a spherical shaped component that fits into the clevis body and allows for swiveling and rotation. This rotation provides flexibility and adjustability for the connected devices.

- Pin – this is a threaded fastener that passes through aligned holes in the clevis body and the spherical ball.

- Cotter pin – a cotter pin works as additional safety measure to secure the pin in place by inserting through a hole in the pin.

Types of ball clevis

There are different types of ball clevis based on design and sizes from different manufacturers and suppliers. The type used depends on the required load capacity and the anticipated functionality in terms of rotating, tensioning or other factors. The following are the most common types of a ball clevis.

U-type ball clevis – this is a clevis which has a U-shaped body and a round pin. It is the most common type of clevis used on overhead transmission lines.

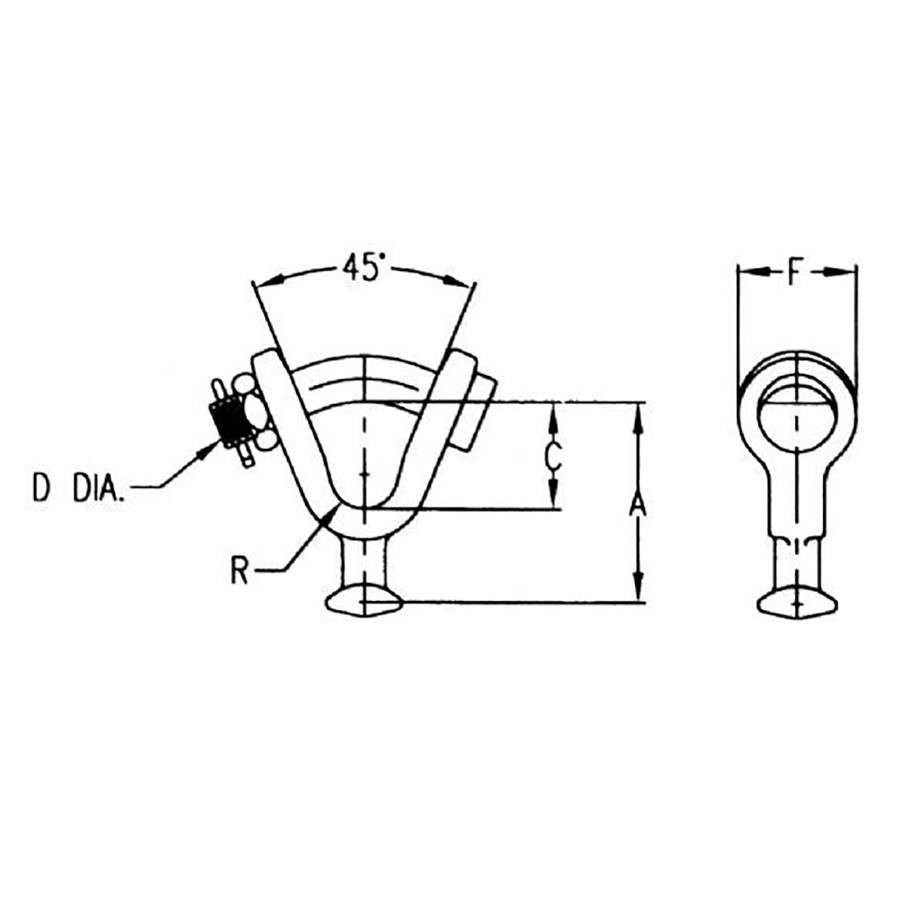

Y-type ball clevis – this is a clevis with a Y-shaped body and a round pin. It works in pole line installations with other pole line hardware and for areas that need a wider range of motion.

Insulator ball clevis – the insulator clevis works mainly for electric power line installations. They have larger balls ends which helps prevent the insulator from slipping.

Captive pin ball clevis – this type of clevis has a locking pin that can not come out. It is hence used in applications with risk of losing the pin.

Applications of a clevis eye

A clevis eye works in transmission lines and overhead poles constructions. They ensure a reliable and flexible connection between the conductor and the other hardware elements. Ball clevis works in applications such as marine applications, construction, mining, oil and gas and agriculture. The other application areas of the clevis eye are as detailed below.

- Ball clevises attach the conductor to other hardware such as insulators, suspension clamps or tensioning devices. This is because they allow the conductor to house changes in tension, wind loading and thermal expansion.

- Ball clevises work in tensioning applications such as long spans or areas with high mechanical stress. They provide a reliable and adjustable connection that allows for proper tensioning of the conductor to maintain the desires sag and clearance.

- Clevis eye facilitates the disconnection and reconnection of hardware components during line maintenance and repair.

- The clevis helps to hang the power transmission lines from towers or poles to provide a secure attachment point for the conductor.

- Ball clevises work in situations where rotational movement and adjustment are necessary. They help reduce stress on the conductors.

Installation guide for clevis eye

Ball clevis installation process for power transmission lines depend on specific design of the ball clevis and the manufacturer/supplier. You should always follow the manufacturer’s guidelines for installation of the clevis eye. Additionally, it is advisable to consult with professionals in the electrical department for safety and integrity of the power transmission line. The following are the basic steps involved in the installation process.

- Prepare all the required tools and equipment which includes wrenches, torque wrench, cotter pins among other components.

- Position the conductor into the loop at the end of the clevis body and ensure the conductor properly aligns within the loop.

- Insert the spherical ball socket into the clevis body to ensure it fits securely. This helps to enable swiveling and rotation capability of the ball clevis.

- Insert the pin through the aligned holes in the clevis body and the spherical ball using the necessary tools to tighten the connections.

- Visually inspect the connection to ensure that all components properly align, tight and secure.

Selecting the best ball clevis for your application.

The selection process for the best clevis eye for a power transmission line involves a series of factors to consider. This ensures the selected clevis is suitable for the specific application. It is advisable to consult with qualified professionals for guidance on the best clevis eye depending on your type of application. The following are the factors to consider when the selecting the best ball clevis for your application.

- Determine the maximum load capacity required for the application. Consider factors such as weight of the conductor, tensioning requirements, wind loading and any additional mechanical stress.

- Consider the size and diameter of the conductor to attach to the clevis eye. This ensures the body and lop are compatible with the conductor size to provide a secure and proper fit.

- Consider the environmental conditions such as moisture, temperature and corrosive elements that may affect the clevis eye. Select ball clevis made from materials that are resistant to the conditions.

- Ensure that the clevis eye is compatible with other hardware components used in the power transmission lines. They include insulators, suspension clamps or tensioning devices.

- It should also meet the relevant industry standards and specifications for power transmission lines applications.

- Consider the manufacturer’s reputation who should provide specifications, load ratings and installation instructions.

Frequently Asked Questions

What is a ball clevis as used on power transmission lines?

A clevis eye is a mechanical component used to connect various hardware elements in overhead line construction. It also attaches the conductor to other hardware such as insulators and suspension clamps.

What are the main components of a ball clevis?

The main components of the clevis eye include:

- Body

- Pin

- Cotter pin

- Ball socket

What are the benefits of a ball clevis on power transmission lines?

Have swivel capability

Provides adjustability

Load distribution

Provides secure attachments

Durable

Comply with standards

What are the limitations of a ball clevis?

Limited range of swivel

Load limitations

Regular maintenance and inspection

Complex installations

High initial costs