A secondary clevis is a component used to provide a mechanical connection between the insulator string and the crossarm. This allows the suspension of conductors and maintaining the required clearances. It attaches to the top end o the insulator string while the bottom end connects to the conductor. Secondary clevis is from materials such as steel or aluminum designed to withstand the mechanical forces and tensions. Also, it has a clevis pin or bolt designed to allow easy installation and removal. Secondary clevis is mostly used in applications such as electrical isolation, maintenance and repairs, mechanical stability and conductor suspension.

Components of the secondary clevis

Secondary clevis has various components that help to provide the best performance of the device. The specific design and configuration of the secondary clevis vary depending on various factors. These factors include the manufacturer, transmission line specifications among others. These components ensure the clevis provides efficient mechanical connection. This is to ensure proper suspension and alignment of the conductors. The following are the main components of the secondary clevis.

- Clevis body – this is the main part of the secondary clevis that provides a connection point for the insulator string. The body holds the clevis pin or bolt hole to allow for the attachment of the insulator string.

- Clevis pin – this can also be a bolt that is removable to secure the insulator string to the body. It is then secured with a cotter pin or nut to prevent it from coming loose.

- Insulator string connection – the clevis has grooves, notches or other features to hold the insulator string in place. It connects to the secondary clevis using a ball-and-socket arrangement.

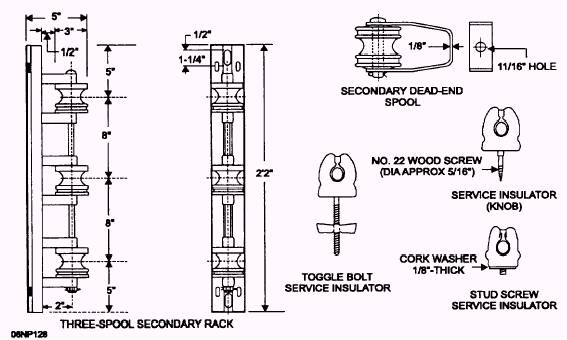

- Attachment hardware – secondary clevis requires additional fasteners o secure the connections. These devices include bolts, nuts, washers or screws.

Common types of secondary clevis in the market

There are several types of secondary clevises used which differ by design and mode of attachment. The selection of the suitable type of clevis depends on various factors. These factors include the design requirements, mechanical forces and specific needs of the transmission lines. The selected type of secondary clevis should support the weight of the spool insulator, withstand the environmental conditions and be cost effective. It is important to consult with industry professionals for guidance on the best type of clevis for your application. The following are the common types of secondary clevises.

Clevis and pin type – this is the most used type of secondary clevis that consists of a clevis body and a removable clevis pin.

Socket eye type – this is a secondary clevis that has a socket eye at the top of clevis body. This provides a secure and stable connection between the insulator string and the clevis body.

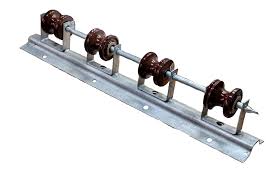

Clevis and spool type – the clevis and spool type secondary clevises utilize a cylindrical spool attached to the insulator string.

Ball-and-socket – the clevis body has a ball-and-socket arrangement. This allows for a flexible and swiveling connection. This provides flexibility and movement to accommodate conductor motion and line vibrations.

Clevis and tang type – this type features a tang or projection on the insulator string. It provides a reliable connection and prevent accidental disengagement.

Applications of secondary clevis

Secondary clevises find use in various application areas in the overhead transmission systems. They contribute to the structural integrity, functionality and longevity of the transmission system. This is because they provide a vital connection point for the insulator string. This facilitates the efficient and secure transmission of electrical power. The following are the common uses of a secondary clevises.

- Electrical isolation – secondary clevises work with insulator strings to electrically isolate the conductors from the supporting structures. This prevents the flow of electrical current through the towers or other objects. This ensures safe and reliable operation of the transmission line.

- Mechanical stability – the clevises also enhance the mechanical stability of transmission lines. This also helps to absorb mechanical forces. This helps to reduce the risk of line failure or damage due to excessive movement.

- Maintenance and repairs – secondary clevises allow for easy maintenance and repair.

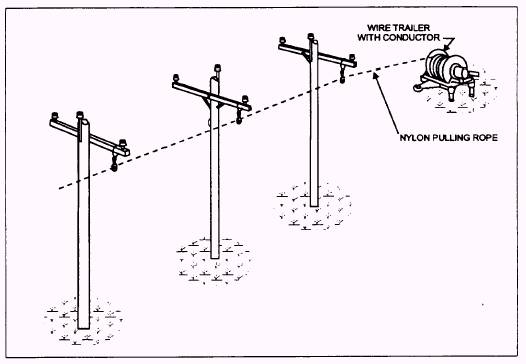

- Conductor suspension – they also help in suspending the conductors. This is through connecting the insulator string to the supporting structure. This helps maintain the desired alignment and tension of the conductors. It also ensures reliable and efficient power transmission.

- Insulator string attachment – the secondary clevises provides a mechanical connection between the insulator string and the crossarm. This allows for a secure attachment of the insulator string which maintains the required clearances.

- Movement and flexibility – the clevis can also provide flexibility and movement to hold the conductor motion and line vibrations. This helps in reducing stress on the conductors and improving the overall resilience of the transmission lines.

Installation guide for secondary clevises on transmission lines

The installation process of the secondary clevis should ensure a secure and reliable connection. The specific installation guide depends on the type of secondary clevis, insulator string and transmission line requirements. Some manufacturers and suppliers provide installation guidelines for the specific secondary clevises. Additionally, it is advisable to consult with industry experts for guidance during the installation process. This is to ensure safe and reliable installation. The steps followed are as follows.

- Gather the necessary tools and equipment required for the installation before you start.

- Ensure the components to use are clean and have no signs of damage. This is to ensure they are in good condition and free from any factors that may affect their performance.

- Identify the location on the crossarm or supporting structure where the secondary clevis will attach.

- Insert the clevis pin through the clevis body and align it with the corresponding hole in the insulator string. Make sure the pin or bolt is of the correct size and type for the clevis and insulator string.

- Position the insulator string on the clevis body and ensure the connection is secure and properly aligned with the clevis.

- Use the suitable tools to tighten the fasteners following the instructions provided.

- Visually inspect the installation to ensure everything is properly aligned, tightened and in good condition. Check for signs of damage, misalignment or loose connections.

How to choose the right secondary clevis for transmission lines

There are several types and designs of secondary clevises available to use in the market. Specific requirements depends on the unique characteristics of each transmission line. Conduct a thorough evaluation of factors to help in selecting the best secondary clevis for the desired application. The following are the main factors to consider.

- Evaluate the load capacity requirements of the transmission lines. Consider factors such as conductor size, voltage level and mechanical forces.

- Determine the most suitable secondary clevises depending on the requirements of the application. Consider flexibility, swiveling capability and ease of installation.

- Ensure the secondary clevis is compatible with the insulator string used. Consider dimensions, attachment method and mechanical properties of the insulator string.

- Consider the material used in the manufacture of the clevises to ensure strength and corrosion resistance.

- Ensure the selected secondary clevises complies with the industry standards and regulations. This is for best electrical performance safety and mechanical strength.

- Choose secondary clevis from reputable manufacturers known for quality products, customer services and technical support.

Frequently asked questions

What is a secondary clevis as used in overhead transmission lines?

A secondary clevis is a device used to provide a mechanical support between insulator string and the crossarm or supporting structure. It provides safety and reliability of the overhead transmission lines.

What are the common types of secondary clevis?

There are several types of secondary clevises used in the overhead transmission lines installations. They include clevis and pin types, ball-and-socket type, socket eye type, clevis and tang type and clevis and spool type.

What are the main benefits of using a secondary clevis?

Secondary clevis provides secure attachment, mechanical stability, flexibility, easy installation, electrical maintenance and compliance with industry standards. These factors help to select the best secondary clevises for your application.

What are the limitations of secondary clevis?

While secondary clevises provides several advantages, they also have various limitations. These limitations include limited load capacity, limited compatibility, requires maintenance and inspection, depends on supporting structures, prone to vibration and fatigue and environmental factors challenges. Addressing these factors before selection can ensure reliable and safe operations of the transmission systems.