A guy thimble is a device used in the installation and support of guy wires in overhead transmission lines. It is also known as a thimble eye or a wire thimble. It is a metal fitting with a circular or oval shape and a closed end. A guy thimble provides a reinforced and protected attachment point for the guy wire as it connects to an anchor point. Guy thimble is from materials that provide strength and corrosion resistance. These materials include as galvanized steel or stainless steel. It has a loop that helps to distribute tension along the guy wire ore evenly and reduce stress concentrations on the wire. They work in applications such as power transmission, telecommunications, constructions and other industries that require support and anchorage.

Components of the guy thimble

Components of the guy thimbles work together to offer optimal performance and support to the applications. The specific components vary depending on the manufacturer and intended application. These components enhance their performance and longevity in various applications. The following are the main components of a guy thimble.

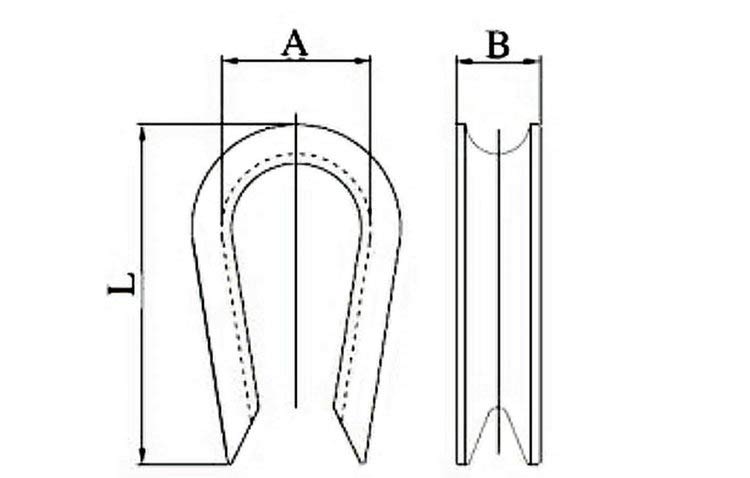

- Body – this is the main structure that is usually circular or oval-shaped designed to hold the passage of the guy wire through its interior.

- Open-end – the open end allows for the insertion and threading of the guy wire.

- Closed end – this is the opposite side of the open end that helps prevent the guy wire from unraveling or slipping out of the thimble.

- Eyelet – an eyelet is the attachment point on the closed end that serves as a connection point for the thimble to the anchor point.

- Smooth interior surface – the smooth surface of the guy thimble is to minimize friction and stress on the guy wire

Types of guy thimble

There are different types and designs of guy thimble that accommodate various applications and specifications of guy wire installations. Additionally, it is advisable to select a guy thimble based on the specific application load requirements and regional standards. Also, you should consult with industry professionals on the most suitable gut thimble for a particular project. The following are the common types of thimbles used on overhead transmission lines.

- Eye thimble – this is a type of thimble that has a small circular opening particularly used for smaller guy wires. It is often used together with a guy hook to increase the surface area of connection.

- Crescent thimble – this thimble has a crescent-shape opening used for larger guy wires. It also works with guy hooks or pole bands.

- Eyelet thimble – this thimble has a small, circular opening with a threaded stud used for smaller guy wires.

- Spurred thimble – this thimble has two or more small projections that help to prevent the guy thimbles from embedding in the pole band. It mainly works in applications where the pole band is from softwood susceptible to damage.

- Swivel thimble – this thimble has a rotating mechanism built into the attachment point to allow the guy wire to rotate freely, reduce strain and potential twisting of the wire.

Applications of wire thimble

Guy thimbles work in various applications that require guy wires for additional support and stability. This means they find use in many applications in the industry. They are particularly used to provide strength, reinforcement, stability, safety and protection in guy wire installations. The following are the main application areas of guy thimbles.

- Antenna installations – thimble support TV antennas, radio antennas or satellite dishes. This is to ensure secure attachment and proper load distribution of guy wires.

- Wind turbines – guy thimbles work in wind turbines to support and anchor guy wires. This ensures a strong and protected attachment point for the guy wires for stability and efficient operation.

- Construction – guy thimbles work in temporary constructions such as signage, fences and scaffolding. This is to provide a reliable and reinforced attachment point for guy wires.

- Power transmission and distribution – they also support guy wires used in power transmission and distribution systems. This is by providing a reliable attachment point for the guy wire.

- Marine applications – guy thimbles works in marine applications to secure and anchor guy wires on offshore platforms or marine communication systems.

- Radio and broadcast – guy thimbles serve as a connection point for guy wires to provide stability, load distribution and proper alignment of radio signals transmitters and broadcasting media.

- Telecommunication – the thimbles support guy wires on antenna towers and communication masts. This is to ensure a secure attachment and proper load distribution.

Guy thimble installation guide

Installation process of the guy thimble depends on the specific requirements of the application and the load requirements. It also depends on the type of guy thimble, manufacturer’s instructions and any industry standards and regulations. Additionally, it is advisable to consult with the industry professionals. This is to ensure proper installations and adherence to safety guidelines. The following is a basic installation guide of the guy thimbles.

- Identify the attachment point on the structure where the guy thimble will install. Ensure it is strong, secure and capable of withstanding the anticipated load and tension.

- Clean the attachment point and ensure it is free from debris, rust and obstructions that may hinder the installation and performance.

- Measure and cut the guy wire to the suitable length and leave some length for adjustments and tensioning during installation.

- Insert one end of the guy wire through the open end of the guy thimble and ensure it goes all the way through the thimble to the closed end.

- Create a loop with the guy wire and ensure it wraps around the closed end of the thimble to allow for easy attachment to the anchor point.

- Attached a looped end of the guy wire with the thimble t the anchor point following the recommended attachment method.

- Secure and tension the guy wire using the suitable tools to achieve the desired tension level.

- Inspect the guy thimble attachment point to ensure everything is secure and properly aligned. Perform a tension test by applying a load or force to the guy wire and ensure it remains secure.

Selecting the best guy thimbles

The selected guy thimble should meet the specific requirements of your application for optimal performance. Selecting heavy duty thimble for long-lasting durability and performance requires considerations of various factors. Additionally, it is advisable to consult with industry experts and technicians for insights on the best thimble for your specific application. The following are the key factors to consider when selecting the thimble.

- Consider the specific type of thimble that best suits your application. This is because they offer different benefits and limitations.

- Determine the diameter of the guy wire you will be using and ensure the guy thimbles is compatible. This ensures a proper fit and secure attachment.

- Evaluate the material used for the guy thimbles which should be durable, corrosion-resistant and capable of withstanding different environmental conditions.

- Ensure that the thimble complies with the relevant industry regulations and standards. This is to ensure performance and safety for guy thimbles.

- Consider the expected load or tension of the installation and ensure the selected thimble can withstand the load.

- Consider the type of the guy thimbles that best suits your application. Choose a thimble that aligns with the requirements and specifications of the project.

- Evaluate the reputation of the manufacturer by checking for customer reviews, certifications and track record of producing high quality products.

Frequently asked questions

What is a guy thimble as used in overhead power systems?

A guy thimble is a device used to connect and support a guy wire to provide reinforced and protected attachment point for the guy wire. It improves the stability and integrity of guy wire installations.

What are the advantages of a guy thimble?

Guy thimble provide reliable attachment points, protect the wire from damage and contribute to overall safety and performance. It also offers various benefits which include easy installations, versatility, safety, durability, protection from abrasion and even load distribution.

What are the limitations of a guy thimble as used in power lines?

Guy thimbles have various disadvantages that address through proper selection, installation and maintenance practices. The main disadvantages of guy thimbles include aesthetic impact, environmental considerations, limited versatility, wire compatibility, limited load capacity and space limitations. These are factors to consider when selecting thimble for your application.