A guy grip is a type of hardware used to secure and end the guy wires in the applications. It is also known as a wire grip or a dead-end grip. The guy grip design grips and holds the guy wire in place to provide a secure attachment point. It also stabilizes the power poles by counteracting the forces of wind and other weather conditions. A guy grip is from durable materials such as steel or galvanized steel. These materials resists rust and various weather conditions. It has serrated jaws on the main body that allows the wire to insert between creating a secure and reliable grip. They work in applications such as utility poles, towers, antennas and other structures that need extra support.

Components of the guy grip

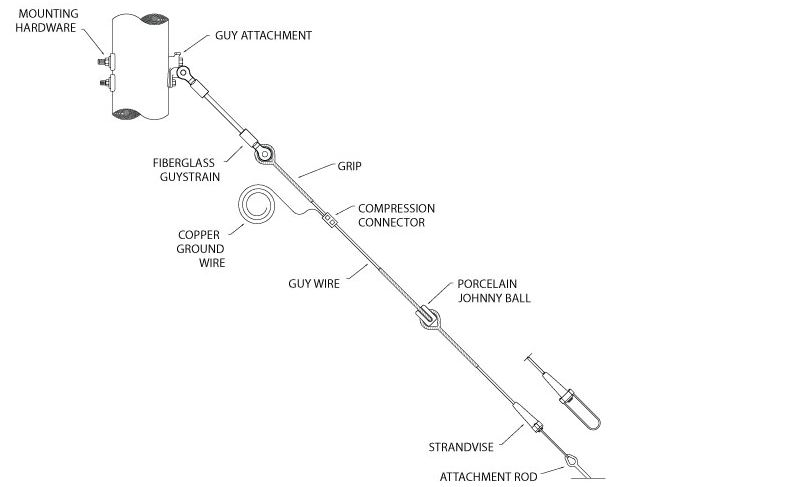

The main work of the guy grip is to secure and end the guy wires in the various applications. Guy grips have various components or features working together to provide the required tension and stability. The specific components vary depending on the intended application, load requirements and regional standards. Different manufacturers offer different designs, sizes and materials suited for a specific application. The following are the main components of the high-load guy grip.

- Body – this is the main feature that provides the structure and stability to the pole or tower.

- Jaws – these jaws are on the inside of the guy grip body designed to bite into the guy wire when tightened. The serrated jaws on the body allow for proper gripping to prevent slippage.

- Wedge – this is available in some guy grips that inserts into the grip body to exert pressure on the guy wire. The wedge exerts pressure against the wire when tightened to increase the grip’s holding capacity.

- Fasteners – fasteners include nuts, bolts and washers that increase the security of the connections. Hey secure the grip body, jaws and wedges to ensure a stable and secure grip on the guy wire.

- Eye/clevis – the eye enables a connection to the structure and allows easy attachment of shackles, hooks or other hardware to the desired point.

Types of guy grips

There are various types, designs and sizes of the guy grips available to select from for your specific application. different manufacturers and suppliers also have different types of guy grips available. The specific type of wire grip selected depends on the type of application, load requirements and guy wire diameter. The following are the common types of wire grips in the industry.

Double U-bolt guy grip – this grip features a double U-bolt design that clamps around the guy wire. They are mostly used in medium to heavy-duty applications.

Preformed dead-end guy grip – the preformed wire easily wraps around and grips the guy wire without the need for separate fasteners. They mostly work in utility pole applications for quick and efficient installation.

Adjustable guy grip – these grips have adjustable mechanism that allows for fine-tuning of the tension on the guy wire. It also provides flexibility in tension adjustments.

Clamp-type guy grip – these grips have a hinged design that allow them to easily open and close around the guy wire. They have serrated jaws inside and they work in various applications.

Suspension-type guy grip – these work in applications where the guy wire needs to hung from a support structure. They have a loop at one end that facilitates suspension. They mostly work in overhead cable support systems and antenna applications.

Specialty guy grips – these include vibration-dampening guy grips and corrosion resistant guy grips. They reduce vibration transfer and work in corrosive environments respectively.

Application areas of guy grips

Guy grips find use in various applications in the field where the installation requires guy wires for support. They provide support, stability and termination of guy wires. The application of the guy grip depends on the requirements of the project, load considerations and regional regulations. The following are the common application areas of the wire grip.

- Guy grips work in TV antennas, radio antennas or satellite dishes to secure and terminate guy wires, ensure proper alignment and stability of antennas.

- Dead-end grips secure and terminate guy wires on wind turbines and provide support and stability to the turbine tower. This ensures optimal performance in renewable energy production.

- The grips also work in construction industry for temporary structures such as scaffolding, temporary fences or signage installations.

- Dead-end grips work in power utility sector for securing and terminating guy wires.

- Guy grips work in marine applications to secure and support guy wires on offshore platforms or marine communication systems.

- The grips work in installation and support of radio and broadcast towers to secure guy wires. They also ensure proper alignment of tall structures used for transmitting radio signals.

- Dead-end grips find use in telecommunication industry for securing guy wires on antenna tower and communication masts.

Installation process of guy grips

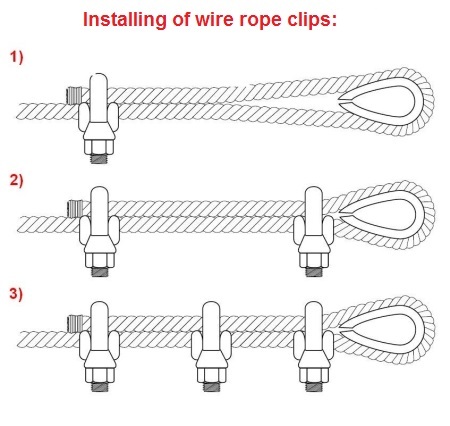

Installation process of guy grips should ensure secure and reliable attachment of guy wire to the structure. Some manufacturers offer guidance and installation instructions to follow during the installation process. The installation also varies depending on the type of guy grip, load requirements and industry standards and regulations. The following is a basic installation process of the dead-end grip.

- Prepare the guy wire by cutting to the desired length and ensure there is extra for proper tensioning and adjustment.

- Choose the right size and type of guy grip matching to the diameter of the guy wire and specific application. Consider load capacity, material and environmental conditions.

- Open the guy grip to create an opening for the guy wire to insert through. Insert the guy wire into the opening and make sure it is properly seated and positioned.

- Close the guy grip around the guy wire by aligning the jaws to ensure that the guy grip do not cause damage or deformation.

- Secure the guy grip using the suitable tools to tighten the fasteners on the grip.

- Inspect the installation after tightening the guy grip to ensure it is secure, properly aligned and shows no signs of slippage.

- Apply tension to the guy wire as needed using suitable mechanisms following the recommended tensioning specifications.

Selecting the best high-load capacity guy grips for power transmission

Different manufacturers and suppliers in the industry provide different specifications of the guy grips for different applications. the selected guy grip should meet the specific requirements of the application. It should also offer combination of performance, reliability and compatibility for your intended application. the following are the key factors to consider when selecting the guy grip for your application.

- Evaluate the ease of installation and maintenance for the chosen guy grip. Select the one that offers user-friendly features such as clear installation instructions to simplify the installation process.

- Ensure the guy wire diameter is compatible with the selected guy grip to ensure a secure and reliable grip.

- Consider the material used to make the guy grip which should be durable, corrosion resistant and capable of withstanding the environment conditions.

- Determine the expected load capacity that the guy grip will handle. It should be suitable for the specific application and load requirements.

- Ensure the selected guy grip complies with relevant industry standards and regulations. This enhances design, performance and safety standards of the grips.

- Examine the design of the guy rip’s gripping mechanism and look for serrated jaws that provide a secure and reliable grip on the guy wire.

- Choose the guy grip from reputable manufacturers known for producing high quality products and customer service.

Frequently Asked Questions

What is a guy grip as used in power transmission systems?

A guy grip is a hardware used to secure and terminate guy wires in various applications. they grip and hold the guy wire in place to provide a secure attachment point and distributing tension along the wire.

What is the difference between a guy clamp and a guy grip?

A guy clamp secures and tensions guy wires to provide stability to the poles. It consists of a body with grooves to hold the guy wire in place while allowing adjustments and tensioning as needed. A guy grip secures and terminates guy wires in various applications. It consists of a series of wires twisted together to form a spiral shape.

What are the advantages of a guy grip?

Guy grips offer several benefits for installation and support of the guy wires that contribute to integrity and performance of various installations. The benefits include low maintenance and inspections, compliance with standards, durability, easy installation, enhanced stability and secure attachment.

What are the disadvantages of using guy grips?

Despite the many advantages, guy grips also have various limitations that limit their adoption. They include adjustment limitations, environmental factors, periodic maintenance, installation complexity, wire size compatibility and load capacity limitations. These factors could resolve through proper selection and maintenance practices.