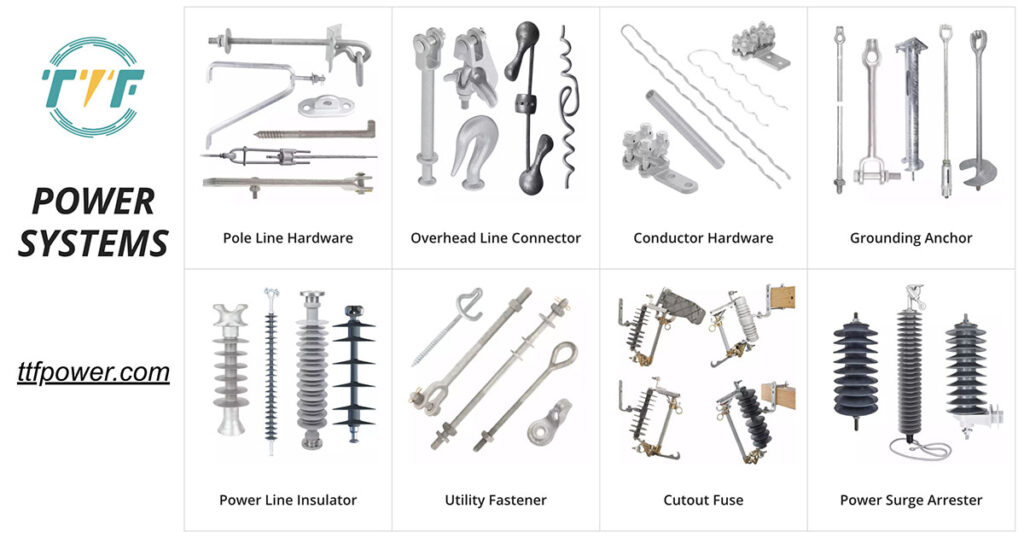

LanzaJet and BioD launched a feasibility study to develop the first sustainable aviation fuel (SAF) production plant in Colombia. The study will assess the technical, economic, and operational requirements to successfully and sustainably put in place the technology in the country. Its commitment is to produce SAF in Colombia using agroforestry residues and energy crops. The study also positions the project as a regional benchmark in South America to produce sustainable aviation fuels. It also aligns with Colombia’s goals to reinforce the strategic role in developing a productive and sustainable industry. This connects rural areas with industrial transformation and social inclusion. It will also help Colombia transition from importing fossil aviation fuel to producing cleaner substitutes. LanzaJet ATJ technology converts ethanol into drop-in jet fuel. This reduces greenhouse gas emissions. Guy clamps are crucial in the structural and logistical setup in the construction or maintenance of infrastructure.

Sustainable aviation fuel (SAF) needs high-capacity power lines for electrolysis, refining, or grid connections. Guy clamps help to anchor utility poles or transmission towers supplying electricity to the facility. They are also crucial components in supporting guy wires that stabilize tall structures against wind and environmental stress. They may also anchor utility poles or transmission towers that supply electricity to the facility. Guy clamps could be part of temporary scaffolding or crane setups and ensure safety and stability for workers and equipment. Additionally, if the project integrates solar panels or wind turbines, guy clamps might secure mounting systems or small-scale wind turbines for auxiliary power. It plays a crucial role in structural integrity, power supply, and safety.

Guy clamps in SAF project development in Colombia.

Guy clamps are mechanical devices used to secure guy wires, which are tensioned cables stabilizing tall structures. They mostly function in energy plants, refineries, telecommunication towers, and aviation fuel storage and distribution facilities. Guy clamps are crucial in temporary scaffolding, support towers for electrical and control systems, and communication towers for remote monitoring. Investing in these components can lower SAF plant construction costs, promote local job creation, and reduce dependence on imports for industrial ports. The project may also need guy clamps, anchor rods, and cable tensioners. Here are the functions of guy clamps in SAF project development in Colombia.

- Stabilizing vertical structures—SAF production plants feature tall distribution columns, large ethanol fermentation tanks, and jet fuel storage silos. The structures need guy wires and clamps for mechanical anchoring.

- Ensuring worker safety—guy clamps help prevent tower collapses or structural failures, maintain cable tension, and offer modular scalability as the plant expands. Guy clamps help prevent catastrophic accidents that can derail project timelines.

- Durability—the SAF projects may be in tropical, humid, or coastal areas. High-quality guy clamps are made from corrosion-resistant materials essential to ensure long-term structural integrity.

- Power transmission & electrical infrastructure—SAF plants need high-capacity power lines. Guy clamps anchor utility poles that supply electricity to the facility.

- Pipeline or storage tank stabilization—guy wires with clamps could reinforce elevated sections. Large storage tanks need stabilization in areas prone to high winds or seismic activity.

- Renewable energy installations—guy clamps secure mounting systems to small-scale wind turbines used for auxiliary power.

Impacts of SAF production plant development in Colombia

The development of a sustainable aviation fuel (SAF) production plant in Colombia offers transformative impacts across the environmental, economic, social, and technological dimensions. Collaboration between LanzaJet and BioD could reshape Colombia’s energy and aviation landscape. The development of an SAF production plant in Colombia helps reduce greenhouse gas emissions, build a green economy, secure energy independence, and elevate Colombia’s role in clean energy transition. The following are the impacts of SAF production plant development in Colombia.

- Environmental impacts—SAF can reduce lifecycle carbon emissions compared to traditional jet fuel. This is crucial in major airports like El Dorado, which consumes 65% of the country’s jet fuel. Colombia’s sugarcane and biomass industries can serve as sustainable feedstock sources, which reduces waste-to-energy gaps.

- Economic impacts—SAF projects generate jobs during construction and dozens of skilled jobs during operation. Ethanol production, transportation, engineering, and plant maintenance industries also enjoy from this production.

- Aviation sector benefits—SAF adoption is key to aviation net-zero goals as it opens doors for partnerships with airlines. It could also mitigate price swings with long-term supply contracts.

- Technology and innovation impact—collaboration with universities and tech incubators can foster innovation in advanced feedstock processing, fuel blending, and carbon capture and reuse.