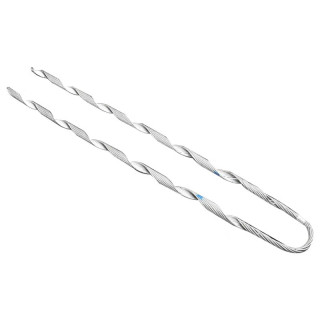

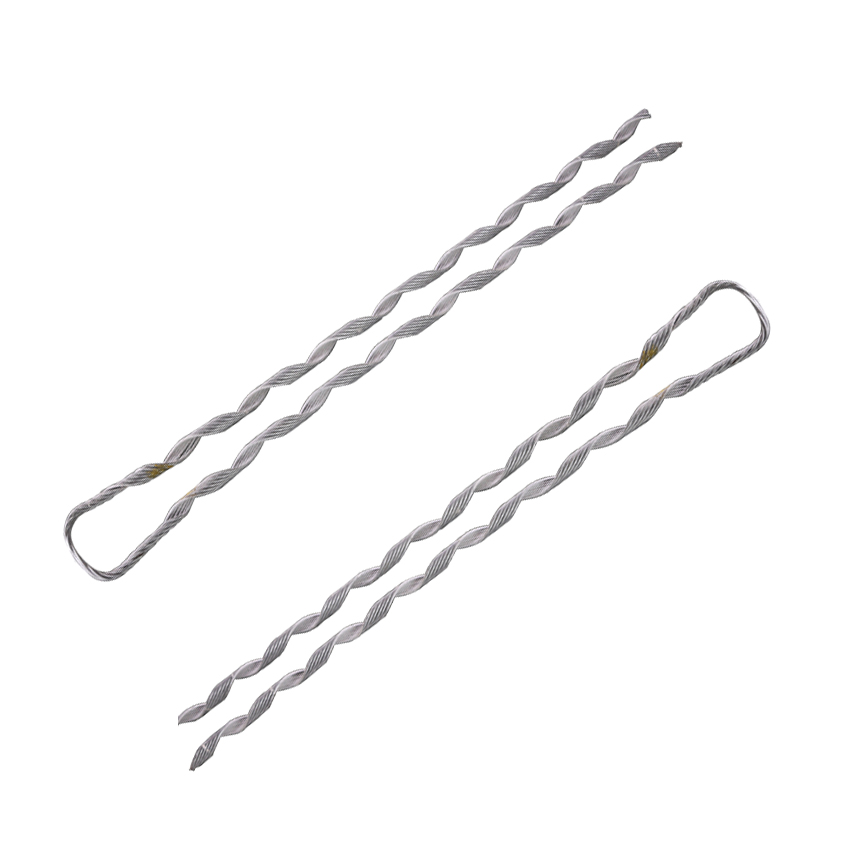

A preformed tension clamp is a tool for holding and supporting conductor cables. It accomplishes this while supplying the strain required to hold them in place. The clamps are from sturdy materials like aluminum or steel. To accommodate the amount of the cable they are to support, they come in a variety of shapes and configurations. Because they mold into the shape before installation, they are refer to as “preformed.” This will guarantee the clamps have an exact fit and work at their best. A firm and stable hold on the cable is from preformed tension clamps. This will stop sagging or slipping even in various environmental circumstances. The clamps work in many different applications, including cable infrastructure, telecommunication and power distribution.

Utilizing preformed tension clamps

Preformed tension clamps have different applications depending on some variables. These consist of the kind of power line, the voltage, the size of the conductor and the surrounding circumstances. Experts in the field can offer more advice on how to use clamps in applications . The preformed tension clamps ae from in the following applications.

- Guy wire – tension clamps guarantee that the guy wires are properly tensioned. This lessens the likelihood of excessive movement or swaying and preserves structural stability.

- Overhead transmisison lines – preformed tension clamps work on transmission lines to support the conductors.

- Railway electrication – preformed tension clamps aid in the security and tensioning of the contact wires during railway electrification. They give electric trains the stability and tension they need to run on electricity.

- Electrical grid – installing tension clamps beforehand is useful in substation settings. They provide support and strain to the wires that link the various parts of the electrical grid. Additionally, they keep the wires’ or busbars’ proper tension.

- Communication lines – the clamps are also suitable for installations involving telephone or fiber optic lines. They support the communication wires’ tensioning and fastening. They also guarantee dependable long-distance signal transmission.

- Distribution lines – these clamps supply power to commercial, industrial, and residential spaces. They aid in supporting and safeguarding conductors. This creates the tension required for effective power distribution.

Installing the preformed tension clamps

For the tension clamps, a few manufacturers on the market provide installation guidelines. They might contain extra actions or things to keep in mind because of the unique clamp design. Ensuring the safe and dependable installation of preformed tension clamps on electricity lines is crucial. An illustrated method for installing the preformed tension clips is as provided below.

- Site survey – check the area to determine the state of the power line. This is to learn where the tension clamps should position. Additionally, they make sure that all required tools and equipment are on hand.

- Clean the conductor – make sure the conductor is clean and clear of any impurities or debris before proceeding. They might have an impact on the tension clamp’s grip.

- Align the gripping elements -line up the tension clamp’s gripping components with the conductor. Make sure they position so they are in contact with the surface of the conductor.

- Put tension on the conductor -if a tensioning device or mechanism is available, adjust it to give the necessary tension.

- Fasteners – tighten the clamp by fastening the tension clamp to the conductor with the included bolts, nuts and other fasteners.

- Alignment – verify the fitted tension clamp to make sure it is securely connected, positioned correctly and free of any flaws or damage.

- Repeat with extra clamps – this includes the places along the power line where a lot of tension is necessary. To make sure that the tension and spacing are appropriate, repeat the same procedures for every clamp.

- Documentation – for future use, keep thorough records of the installation procedure. Dates, the kinds utilized and any other observations go here.

How to maintain preformed tension clamps

For the system to remain safe and dependable, the preformed tension clamps need regular maintenance. This aids in the early detection of possible problems and helps to avoid unplanned breakdowns. It also contributes to the clamp’s and the power systems’ longer lifespan. A basic method on maintaining and inspecting preformed tension clamps is as provided below.

- Determine a regular inspection schedule based on the circumstances. These circumstances include usage, the installation’s criticality and the surrounding environment.

- Examine the clamp for indications of wear, corrosion or damage. You should also look for any symptoms of deformation, cracks or loose parts.

- Verify that the grasping mechanism makes contact with the conductor and that the parts line up as expected.

- Look for rust on the clamp’s materials, as this can affect the device’s conductivity and mechanical strength.

- If necessary, check and adjust the tension to make sure it satisfies the essential criteria.

- Check the clamp’s exposure to external factors, including weather, humidity and variations in temperature.

- Keep a thorough record of every inspection, noting the date, the place, the observations and any actions performed.

- To improve the clamp’s functionality or grip, clean it by removing any dirt, debris, or other impurities.

- Any clamp that exhibits noticeable deterioration, wear or damage should be promptly replaced or repaired.

Auditing manufactured tension clamps

Preformed tension clamp must undergo tests to guarantee its dependability and functionality. The tests aid in ensuring that preformed tension clamp fulfill the necessary performance requirements for the producers. This is to guarantee overhead cable systems’ dependability and security. Furthermore, it is crucial to choose clamps that have passed the different tests to guarantee safety for your use. The several tests for preformed tension clamps are as listed below.

- Tensile strength test – this determines the greatest load that the clamp is capable of supporting before failing. It entails tightening the clamp with increasing force until it breaks. This is to learn the safe operating load and tension-withstanding capacity of the clamp.

- Fit and compatibility testing – this makes that the clamp is both compatible with other parts and fits the cable. It include confirming dimensions, tolerances and cable type compatibility.

- Corrosion resistance – this entails determining the material’s ability to withstand corrosion particularly in outdoor settings. It might entail being around caustic substances, dampness or salt spray.

- Vibration and fatigue tests – these entail modeling potential vibrations and cyclic loading scenarios for the clamp. This aids in evaluating the durability and fatigue strength of the preformed tension clamp.

- Quality control inspections and certification – this is from the appropriate regulatory agencies. It is to guarantee that they adhere to industry norms and guidelines.

- Material analysis – the tests make sure the clamps are strong, long-lasting and corrosion-resistant according to the requirements. Verifying the materials’ quality and appropriateness for the intended use is another benefit of the examination.

- Environmental testing – this is testing in the environment involves exposing the clamp to various environmental factors. These consist of changes in temperature, exposure to UV rays and mechanical stress. Evaluating the clamps’ performance in various operating scenarios is helpful.

Symptoms of a preformed tension clamp failing

To guarantee their dependability and safety, it’s critical to recognize the warning indicators of a failing preformed tension clamp. Finding and fixing failure indicators is simpler by performing maintenance and inspections. It is also advisable to speak with certified specialists to check the clamps’ condition and determine the best course of action. The typical indicators to watch out for are as listed below.

- Visible damage – look for any obvious indications of deterioration like corrosion, deformation or cracks on the clamp. They could erode the clamps’ strength and make it harder for them to grip the cable.

- Sagging – an increase in sagging could show that the clamp isn’t providing enough tension between the support points.

- Electrical problems – look for indications of electrical problems, such as sparking, overheating or power variations. These can show that the clamp is breaking and vibrating the cable.

- Visible wear – check the gripping surfaces of the clamp for indications of wear. The ability of the clamps to sustain tension and support may weaken from excessive wear.

- Slipping cable – loose cables show that wear or damage is causing the clamp to lose its hold.

- Corrosion and rust – in outdoor settings, rust on the surfaces could compromise the structure’s strength and cause failure.

- Physical movement – unexpected changes in the clamp’s position could state that it is loose or malfunctioning.

- Age and maintenance history – take into account the clamp’s age and maintenance background. The clamp may become weaker due to wear and tear, necessitating replacement.

Frequently asked questions

Preformed tension clamps are typically by wrapping around them around the cable and securing them with bolts or other fasteners. Proper installation involves ensuring the clamp fits the cable securely and the tension is as per the instructions.

Preformed tension clamps have designs to perform reliably under various environmental conditions. This is including temperature extremes, humidity and exposure to UV radiation. Proper material selection and corrosion-resistant coatings contribute to their performance in outdoor environments.