The production of green hydrogen in South America has the potential to transform the energy industry. This is due to the area’s plenty renewable energy resources and the worldwide transition toward sustainable energy options. Countries in South America are formulating strategies and initiatives to establish themselves as significant participants in the green hydrogen market. For example, Chile has implemented strategies for green hydrogen with the goal of generating up to 160 million tons of clean energy each year by 2050. Countries such as Brazil, Colombia, and Argentina are working to shift from fossil fuels to renewable energy by emphasizing green hydrogen. Major funding from global financial institutions is backing the initiatives. This advancement encounters many obstacles, such as market requirements, technological adjustments, regulatory structures, and capital necessities. Electrical insulators guarantee the secure and effective functioning of the electrical infrastructure.

Green hydrogen production involves the electrolysis of water using renewable energy sources like solar and wind power. Electrical insulators support power lines to prevent them from sagging. They also prevent them from coming into contact with other objects. The insulators prevent electrical arcing, which can lead to damaged equipment. They are able to withstand harsh environmental conditions to ensure their long-term reliability. Electrical insulators contribute to the efficient and sustainable operation of green hydrogen production. This is by ensuring the safe and reliable transmission of electricity. This article explores the technologies used in the development of green hydrogen and the importance of using guy wires in the infrastructure.

Functions of electrical insulators in the development of green hydrogen

Electrical insulators play a crucial role in the development of green hydrogen in South America. They contribute to the region’s transition to sustainable energy sources. electrical insulators have designs that allow easy inspection and maintenance. This reduces downtime and reduces the risk of equipment failure. Electrical insulators ensure protection, efficiency, safety, and regulatory compliance. Countries like Chile, Brazil, and Argentina are investing in hydrogen production. They would need robust insulation systems to ensure their success. Discussed below are the functions of electrical insulators in green hydrogen development.

- Electrical safety—insulators prevent unintended current flow between conductive parts. This reduces the risk of electrical hazards in hydrogen production facilities.

- System integrity—electrical insulators provide mechanical support and electrical isolation. This helps to maintain the integrity of electrical systems within hydrogen production plants.

- Environmental conditions—the insulators are able to endure the harsh environmental factors. These include extreme temperatures and humidity. This ensures the plants maintain consistent performance in diverse climates.

- Renewable energy integration—electrical insulators enhance grid efficiency and ease the integration of renewable sources.

- Mechanical support—the insulators provide mechanical support to electrical components. Such components include conductors, switchgear, and electrolyzers. They help plants withstand earthquakes and strong winds in the region.

- Energy efficiency—the insulators prevent energy losses by reducing leakage currents and ensure efficient energy transfer. They prevent the unwanted flow of current, which reduces energy waste.

- Withstanding high voltage surges—electrical insulators protect the infrastructure from overvoltage events. Voltage surges caused by lightning strikes can cause damage to transformers and electrolyzers.

Technologies employed in the development of green hydrogen in South America

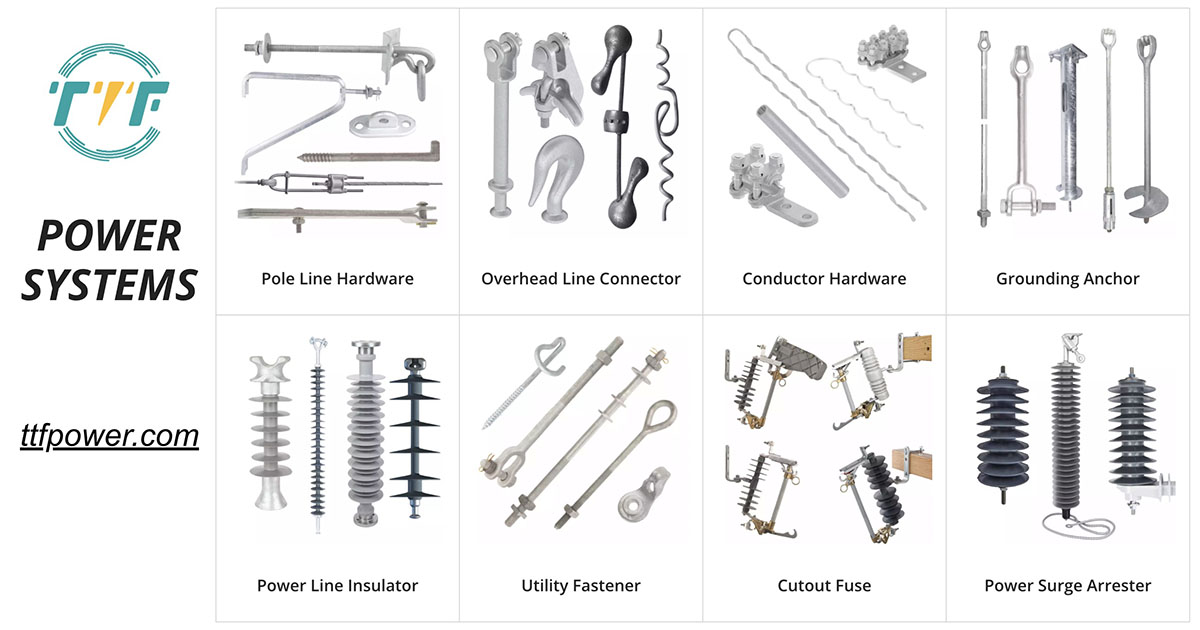

The advancement of green hydrogen in South America utilizes various technologies to use the abundant renewable energy resources. Nations such as Chile and Brazil are at the forefront with their national strategies and large investments. This aims to increase green hydrogen production to establish a significant presence in the worldwide hydrogen market. TTF Power supports the development of green hydrogen in south america. We provide high quality overhead line hardware, transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. The main technologies employed in the advancement of green hydrogen in South America are as follows.

- Electrolysis—this method employs electricity to divide water into hydrogen and oxygen. This procedure primarily relies on renewable energy sources to create green hydrogen.

- The effectiveness of green hydrogen relies on the integration of renewable energy sources. The renewable energy resources ease affordable, clean hydrogen generation in South America.

- Biomass gasification—this process of biomass gasification is an effective way to generate green hydrogen. This procedure consists of transforming organic substances into gases rich in hydrogen.

- Carbon capture and storage—these technologies aid in lowering emissions from current hydrogen production techniques.

- Ammonia production—green hydrogen can react with nitrogen to generate green ammonia. Green ammonia functions as a transport medium for hydrogen and acts as an eco-friendly fertilizer.