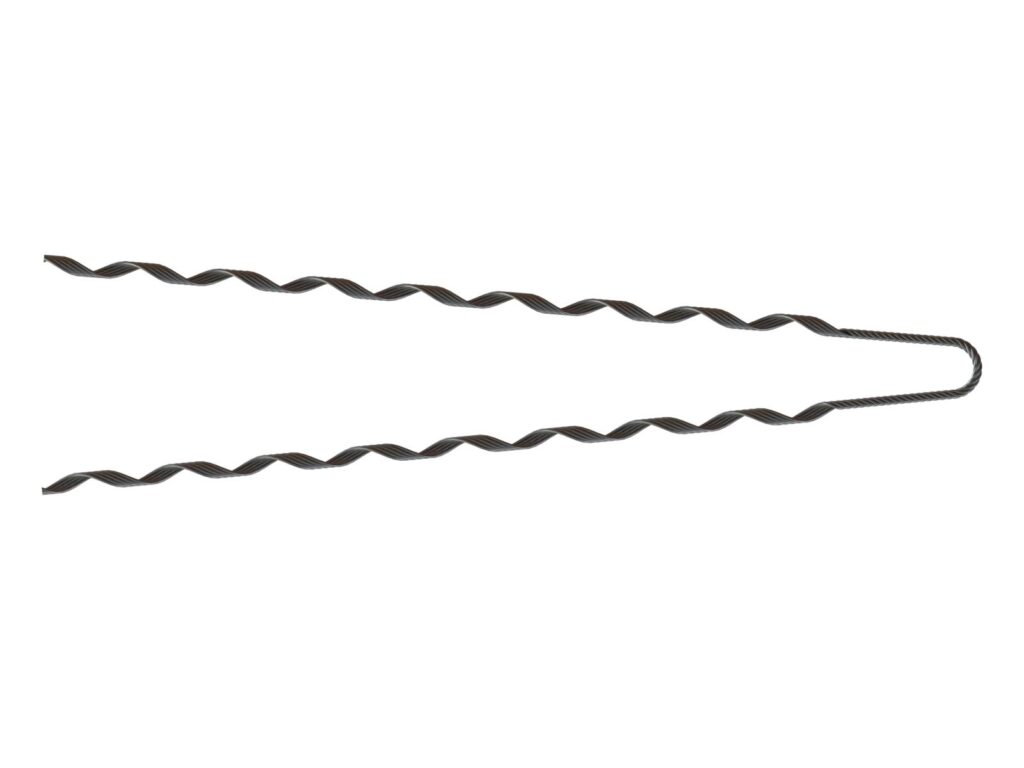

A distribution grip dead end is a component used to provide support and tension to the conductors. This is to ensure the stability and reliability of the entire line system. Distribution grip dead end have a robust design, corrosion resistance and ease of installation. A distribution grip dead end is also simply known as a dead end grip. It has a design that helps withstand high mechanical loads including ice, wind and weight of the conductors. Distribution grip dead ends should be compatible with various types and sizes of conductors used in overhead lines. Their versatility ensures they are applicable across different projects and configurations. The dead-end grips are from materials with excellent corrosion resistance properties. These materials include steel, aluminum and composite materials. Distribution grip dead ends help prevent sagging or swaying under varying weather conditions.

Key features of distribution grip dead end

Distribution grip dead ends have several features that contribute to their effectiveness. The dead end grips may have various characteristics. These include high strength, adjustable tensioning, ease of installation and versatility. The features make them essential components for ensuring the stability, performance and durability. The following are the key features of a distribution grip dead end.

- Secure conductor termination – they have designs to terminate the ends of conductors in overhead power lines.

- Multiple gripping points – the dead end grips have many gripping points along their length to hold the conductor. These points distribute the load to reduce stress concentrations. They also help reduce the risk of damage to the conductor.

- Material – they are available in different materials such as aluminum or aluminum alloy. The materials help to ensure the compatibility with the conductors used.

- Mechanical strength – the dead ends also provide mechanical strength to the entire power system. This is by anchoring the conductors securely.

- Adjustable tensioning – dead ends have adjustable tensioning mechanism to allow for precise change to the tension. This helps to maintain the tension levels to enhance the stability and performance of the overhead line.

- Vibration damping – some of the dead ends contribute to the damping vibrations in the conductors to reduce wear and fatigue.

- Cost effectiveness – the dead ends provide cost effective solutions for securing conductors. They also help maintain the integrity of power distribution systems.

- Resistance to environmental factors – the dead ends also show resistance to environmental factors. These includes factors such as weather, wind, ice and UV radiation.

- Ease of installation – some of the grip dead ends provide easy installing and removal. This helps to ease maintenance activities.

- Corrosion resistance – they manufacture from corrosion resistant materials like steel and aluminum. These materials protect them against corrosive conditions.

Challenges and issues facing use of distribution grip dead end

Distribution grip dead ends provideseveral benefits to the transmission and telecommunication lines. They also face various challenges and issues that may hinder their use in various applications. Addressing these challenges needs various approaches that include regular maintenance and inspection. Also, addressing these issues, operators can ensure their reliability and longevity. The following are the several challenges facing use of distribution grip dead ends.

- Technological advancements – new materials, designs and installation techniques for distribution grip dead ends may emerge. This requires the operators to continually update their infrastructure to remain competitive.

- Compatibility issues – compatibility between the dead ends and specific conductor type and size used can be a challenge.

- Mechanical failure – the dead-end grips are prone to mechanical loads and stresses which can lead to fatigue and failure. It should thus have designs to handle the expected loads and reduce line damage.

- Improper installation – incorrect installation of the dead ends can lead to reduced gripping effectiveness, improper tensioning and damage to the conductor.

- Maintenance requirements – distribution grip dead ends need regular inspection and maintenance. Access to the overhead lines for maintenance can be difficult and hazardous in remote areas.

- Cost considerations – the dead-end grips may have high upfront costs. They also have costs associated with installation, maintenance and replacement.

- Corrosion and environmental degradation – the dead-end grips are susceptible to corrosion and environmental degradation. They may face harsh environments with high humidity, salt exposure or chemical pollutants.

Cost comparisons and considerations of dead-end grips.

Distribution grip dead ends come in various prices depending on several factors. This requires careful consideration of these factors and conducting a thorough cost analysis. This helps to make informed decisions when selecting the dead-end grips. Additionally, it is advisable to ask for quotation from different suppliers for comparisons. The following are the common factors influencing prices for distribution grip dead ends.

- Initial cost – the upfront costs of distribution grip dead ends vary depending on various factors. These include material, design, manufacturer and quantity purchased. Dead end grips are from materials like aluminum and steel which may have a higher initial cost.

- Maintenance costs –dead ends need periodic maintenance to ensure proper functionality and durability. The costs include inspection, cleaning, lubrication and potential replacement of damaged components. Grips with easy maintenance designs have longer service intervals and thus lower costs.

- Operational efficiency – the grips contribute to operational efficiency such as those with built-in features to mitigate conductor damage. Operational efficiency considerations include factors such as energy losses, downtime and reliability.

- Total cost of ownership – consider the total cost of ownership over the products lifespan. This includes the initial cost, installation, maintenance and potential replacement costs. Considering this factor also helps to identify the most cost-effective solution.

- Durability and lifespan – their durability and lifespan depend on several factors. These include material quality, corrosion resistance and design strength. Corrosion resistant dead end grips have a longer service life which reduces replacement costs over time.

- Installation costs – installation costs include labor, equipment and any extra materials required for installation. Grips with easy installation features have lower installation costs. This is as compared to more complex designs. Also, consider factors such as accessibility of the installation site and need for specialized training.

Supplier or vendor information for distribution grip dead ends

There are several reputable suppliers known for providing distribution grip dead ends in the market. There are several factors that influence the supplier selection for the dead end grips. These factors also help to select a supplier that meets your project needs. This is while ensuring quality, reliability and customer satisfaction. Additionally, it is advisable to request references or testimonials from other customers to assess the supplier’s reputation. The following are the factors that influence supplier or vendor selection for the grips.

- Product quality and reliability – the selected suppliers should offer dead end grips that are of quality and are reliable. Ensure they meet industry specific standards to ensure durability and performance.

- Product range and customization – select a supplier that provides a wide range of distribution grip dead ends. also, consider the ability to customize grips to accommodate different conductor types, sizes and installation configurations.

- Lead times and availability – consider the supplier’s lead times and ability to meet your project deadlines. Efficient production processes can help ensure timely delivery of distribution grip dead ends.

- Certification and compliance – ensure the selected supplier’s grips follow relevant industry standards. Check for certifications such as ISO or other specific industry standards to verify quality.

- Industry experience and reputation – select suppliers with a proven track record of experience and expertise in providing the grips.

- Price competitiveness – it is important to balance cost with product quality and reliability. Compare pricing from different suppliers to ensure you get competitive rates.

- Technical support – select a supplier that offers technical support and expertise to assist with product selection and installation.

Community forums and engagement for dead end grips

Engaging in community forums can be a way to gather information, share experience and connect with others. They also provide a platform to contribute to discussions and ask questions from professionals. It may also help to stay informed about advancements and trends in the field of distribution grip dead ends. The following are the community forums and engagement channels for distribution grip dead ends.

- Utility industry forums – these include Utility Dive and Utility Products Magazine. They provide discussion boards where professionals in the utility industry share insights and discuss various topics.

- Online communities and forums – this is including websites like Electrical Engineering Stack Exchange or Eng-Tips Forums.

- Manufacturer websites and forums – many manufacturers host online forums or discussion boards on their websites. Customers can ask questions, share experiences and provide feedback on their products.

- Webinars and virtual events – take part in webinars or events hosted by industry organizations or manufacturers.

- Social media platforms – join platforms such as Twitter, Instagram or Facebook groups related to distribution grip dead ends. This helps to stay updated on discussions, news and events related to overhead line hardware.

Frequently asked questions

Key features include high-strength construction, many gripping points, corrosion resistance and adjustable tensioning. They also include ease of installation, versatility, reliability and compliance with industry standards.

Challenges and issues include mechanical failure, corrosion and environmental degradation, improper installation and compatibility issues. They also include maintenance requirements, cost considerations, regulatory compliance and technological advancements.