A strand vise is a crucial component used to support and secure the conductor strands in overhead transmission lines. It helps to ensure the stability and tension of the conductors that carry electricity. A strand vise is from materials like high strength aluminum, steel or other corrosion resistant alloys. This helps them to withstand outdoor conditions in south America for reliability. Common examples of the strand vise include suspension strand vise, repair strand, helical strand vise and automatic strand vise. They find use n applications such as dead ends, vibration damping, repair and maintenance, high tension adjustments and automatic tension control.

Key features of strand vise

Strand vise has various important features that helps to ensure the stability and tension control of the conductors. These features help them to improve functionality and effectiveness. The following are the key features.

- Material – strand vise is from durable materials like aluminum, steel or other alloys, these materials help to resist corrosion and withstand other outdoor conditions.

- Tension adjustment – they have designs to allow for tension adjustment to maintain the proper tension in the conductor strands.

- Dead-end design – the design facilitates a secure anchoring point for the conductor to prevent it from moving.

- Suspension design – the design provides a reliable support system for conductors over long spans. These features evenly distribute the weight and maintain the correct spacing between conductors.

- Corrosion resistance – the strands have coatings or materials that resist corrosion to ensure longevity.

- Load capacity – the loads capacity of the strand should match the specific requirements of the transmission line.

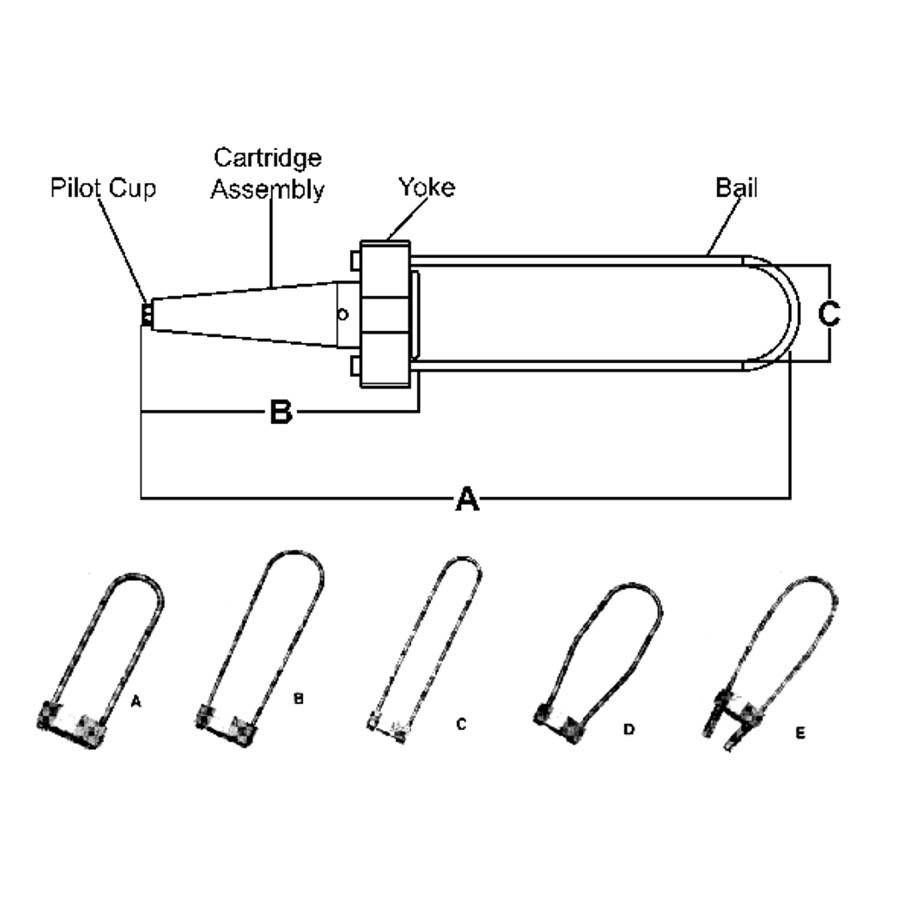

- Gripping mechanism – the mechanism holds the conductors in place to prevent them from slipping even under high tension.

- Vibration dampening – the vises have features to reduce the impact of wind-induced vibrations on the conductors. This helps to reduce wear and tear and maintain the stability of the transmission line.

- Ease of installation – it also has a straightforward installation and maintenance to allow for efficient and cost-effective operations.

- Automatic tensioning – the tensioning helps to adjust the tension in the conductor strands automatically.

Selection and installation of strand vise

Selecting the strand vise helps to ensure the proper functioning and reliability of the overhead transmission lines. It includes considering several factors such as conductor type, application, load capacity, material, tension adjustment mechanism, vibration dampening, installation and maintenance. The installation process should help to ensure the stability and tension of the conductor strands. Additionally, it is advisable to consult professionals for in the industry for guidance. The following is basic installation process.

- Preparation – gather all the necessary tools required for the installation. This is including strand vise, fasteners, wrenches, insulating material, gloves and glasses. Ensure you follow all the safety measures are in place.

- Positioning – position the strand vise at the designated location on the transmission line. This is to ensure the level it is level and in alignment with the conductors.

- Secure the conductor – secure the conductor to the anchor point which involves looping the conductor around the anchor point.

- Attachment – use suitable fasteners to attach the strand vise to the supporting structure.

- Tightening – gradually tighten the fasteners using wrenches to secure it in place. Ensure the strand vise grips the conductor but without over-tightening which could damage the conductor.

- Tension adjustment – use it to achieve the desired tension in the conductor following the manufacturer’s recommendation.

- Insulation – the insulating material helps to prevent electrical contact between the conductor and the strand vise.

- Final inspection – inspect the installation to ensure the strand vise is securely attached. Ensure the conductor is properly tensioned and no signs of damage.

- Documentation – maintain the records of the installation including date location and types of strand vise.

Maintenance and inspection of strand vise

Proper maintenance and inspection of strand vise helps to ensure the safe and reliable operation. The diverse weather climate and environmental condition in South America influence the frequency of this activity. In addition, it is important to seek professional assistance for maintenance and inspection. The following is a basic maintenance and inspection of the strand vise in South America.

- Establish a regular inspection schedule for strand vises along transmission lines. This may be annually of semi-annually.

- Conduct regular visual inspections to check for signs of wear, corrosion or damage. Look for rust, loose fasteners or any visible defects.

- Consider the environmental conditions in south America which influence the inspections and maintenance. These include high humidity, salt exposure, tropical and temperate regions.

- Apply protective coatings or galvanization to prevent corrosion on the strand vise.

- Check and adjust the tension on the conductor strands. This is to ensure the strand vises maintain the suitable tension to prevent conductor sag.

- Lubricate moving parts and mechanisms of the strand vise to prevent friction and ensure smooth operation.

- Inspect the systems to verify their effectiveness especially in areas prone to strong winds or vibrations.

- Maintain detailed records of all inspection. This is including date, location, findings and any other necessary actions.

Comparative analysis of strand vise in South America

A comparative analysis of strand vise helps to identify the strengths and weaknesses of different products. It involves assessing and evaluating the different types, design, brand and manufacturers in the market. It helps to select the best strand vise in the market for your particular system. Also, it is advisable to consult with industry professionals for guidance on the best product in the industry. The following are the factors to include in the comparative analysis in South America.

- Type and model – compare the different types and models of strand vises available in South America. Assess the types commonly used and which manufacturers produce them.

- Load capacity – compare the load bearing capacity of different strand vises. Ensure it can handle the specific loads and tensions required in the region.

- Vibration damping – confirm the strand vises have features designed to reduce vibration and sway.

- Reputation and reviews – look for customer reviews, feedback from the utility companies and testimonials from professionals.

- Environmental adaptability – consider the environmental conditions South America. This is including high humidity, salt exposure in coastal areas.

- Installation and maintenance services – evaluate the availability of installation and maintenance services. Manufacturers should provide services and maintenance and upkeep strand vises.

- Materials – evaluate the materials used in construction of strand vises. Consider factors like corrosion resistance, durability and adaptability in South America.

- Tension adjustment mechanisms – assess the tension adjustment mechanisms offered by different manufacturers. Check for advances in tensioning features for environmental conditions.

- Cost and budget – compare the costs associated with different options. Evaluate whether certain manufacturer offer competitive pricing without compromising on quality.

Certifications and standards in South America

There are various certifications and standards that ensure their quality and safety. These standards and certifications vary depending by country for the use of strand vises. Additionally, it is important to work with reputable manufacturers and suppliers. They help provide documentation demonstrating compliance with these standards. It is advisable to ensure the chosen strand vises meet specific requirements of the region. The following are the certifications and standards for strand vise in South America.

- IEC standards – these are standards that provide international standards for electrical and electronic equipment.

- IEEE standards – these standards for various aspects of electrical and electronic technologies.

- National standards – each South American country has their own set national standards and regulations. They apply to electrical components and transmission infrastructure.

- ISO certifications – these are standards that ensure the quality management standards. It can be signs of commitment to quality and consistency.

- ASTM international – These are standards for materials, products, systems and services often referenced worldwide.

Regional markets for strand vise in South America

There are various factors that influence the use of strand vises in the South American market. They also help to ensure the quality and safety of electrical infrastructure components. These factors include electrical infrastructure needs, urbanization and manufacturers in the market. The following are the factors that shape the regional market for strand vise in South America.

- Electrical infrastructure development – this includes the expansion of transmission and distribution lines.

- Renewable energy projects – these includes projects like wind farms and solar power installations. Projects require strand vises for conductor support in robust electrical infrastructure.

- Environmental considerations – strand vises should withstand a range of environmental conditions. This is from tropical to mountainous regions.

- Safety and standards – compliance with local and international safety and quality standards. They help to increase the use of strand vise.

- Energy efficiency – these are initiatives which influence the selection of energy efficient components. This is including strand vises.

Frequently asked questions

It is a crucial component used to support and secure the conductor strands in overhead transmission lines. It helps to ensure the stability and tension of the conductors that carry electricity across distances.

Consider factors like conductor support and tensioning, span supports, vibration damping, repair and maintenance, automatic tension control and high-tension control.