Corona ring is a device used in overhead transmission lines to minimize the occurrence of corona discharge. It is also known as a grading ring or a control ring. Corona discharge is an electrical spectacle that can happen at high voltages. This is when the electric field strength around a conductor becomes too high. This results in energy loss, audible noise, radio interference and damage to the transmission components. Corona ring is from a series of metallic rings installed around the high voltage conductors. It prevents the onset of corona discharge by evenly distributing the electric field around the conductor. It also helps ensure safe and efficient operation of the transmission line by reducing the effects of corona discharge.

Components of the corona ring

Components of the corona ring work together to create a corona control system that helps manage the electric field. They help to reduce the effects of corona discharge in overhead transmission lines. The following are the main components of the corona ring.

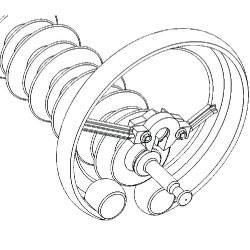

- Metallic rings – these are the core components of the corona ring. They position around high-voltage conductors. The conductive materials help to control the electric field.

- Insulators – these help to separate the corona ring from the supporting structure. It also helps to prevent electrical current from flowing between them.

- Spacing elements – these elements help to maintain a specific distance between the ring and the conductor. This is to ensure the effectiveness of the corona control by properly distributing the electric field.

- Support structure – the ring attaches to the support structure to keep them at a specific distance from the high-voltage conductor.

- Mounting hardware – these include nut, bolts, clamps and washers used to secure the corona rings.

Types of corona ring

There are several types and designs of the corona ring with different configurations to select from. Each design helps to meet the specific requirements of the application. Selection of the corona ring depends on several factors. They include voltage level, configuration and specific corona-related challenges. Each type of the corona ring offers various benefits and solutions for minimizing corona discharge and its effects. The following are the common types of corona ring.

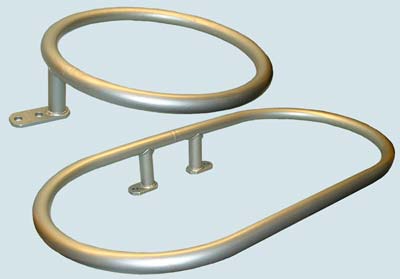

- Flat disc corona ring – this is a flat, circular ring that installs vertically to the axis of the conductor. This creates a uniform electric field distribution.

- Suspension corona rings – these rings suspend vertically below the high-voltage conductor. This helps to maintain a uniform electric field distribution.

- Bundled conductor corona ring – this are two or more corona rings bundled together to help distribute the electric field among the individual conductors.

- Semicylindrical corona rings – these have a semicylindrical shape usually placed around conductors. This is to help maintain the electrical field.

- Multi-layer corona rings – these consists of multiple concentric layers of conductive materials. These materials design addresses higher voltage applications.

- Interphase spacer rings – these rings install between phases of a transmission line. They help to control the electric field between adjacent phases. This is to reduce the potential for corona discharge between them.

- Capacitor type corona ring – these help to introduce capacitance between the conductor and the corona ring.

Applications of corona rings

Corona rings find use in various applications within the field of high-voltage power transmission and distribution. They help to manage and control corona discharge on the transmission lines. They also help to maintain the integrity and performance of high-voltage systems. This is by minimizing corona discharge and its problems. The common application areas of the corona ring are as follows.

- Overhead transmission lines – corona rings help to mitigate the effects of corona discharge on transmission lines. They help reduce energy loss, audible noise, radio interference and potential equipment damage.

- Converter stations – corona rings help control corona discharge on converter transformers, bushings and other high-voltage components.

- High-voltage testing – the rings also help prevent unwanted corona discharge. This discharge could interfere with the accurate testing results.

- Lightning arrestors – corona rings are part of the design of lightning arrestors. They aid in the prevention of corona discharge around these protective devices.

- Substations – the rings work on high-voltage components like insulators and bushings to help control corona discharge.

- Switchyards – the rings manage corona discharge on equipment such as circuit breakers, disconnectors and other high-voltage devices.

- Wind energy – the rings manage corona effects on high-voltage components in wind turbines and generators. They enhance the reliability of the electrical infrastructure.

Installation process of corona rings

The installation process should ensure proper placement and effective corona control. Follow all the necessary safety protocols. This is to ensure their effectiveness in controlling the corona discharge. Additionally, follow the manufacturers guidelines to ensure the corona control system functions as intended. This also helps to improve overall efficiency and reliability of the high-voltage system. The following is a basic installation procedure of the corona ring.

- Gather all the necessary tools, equipment and materials required and inspect the corona for any defects or damages.

- Follow all the safety protocols such as wearing suitable personal protective equipment for the work environment.

- Identify the locations on the transmission line, substation equipment or other components where the corona ring will install.

- Clean the installation area to remove dirt, dust, grease and other contaminants that could affect adhesion.

- Follow the manufacturers guidelines to attach corona rings to the conductors, insulators or other components. Use the suitable mounting hardware such as clamps, bolts, or insulators to secure the corona rings in place.

- Maintain the recommended spacing between the corona ring and the conductor. Ensure the uniform alignment of the corona rings along the length of the installation.

- Install the corona control system as per the manufacturer instructions. Ensure they properly settle and secured to prevent electrical leakage.

- Conduct a thorough visual inspection of the installed corona rings to ensure they align and attach securely.

- Test the installations to verify the effectiveness of the corona control system. Document the installation process including location, date and any relevant observations.

Selecting the best corona rings

Selecting the best corona ring involves considering various factors. This aims to ensure they are suitable for your specific application. The selection of the rings will depend on the voltage levels, environmental conditions and the applications. The selected corona ring should ensure safety, reliability and effectiveness of the transmission lines. The following are the common factors to consider when selecting corona rings.

- Select a corona ring that can handle the voltage level of your transmission or distribution system.

- Consider the type of application intended for the corona ring. Different designs work in overhead transmission lines, substations, switchyards and other applications.

- Ensure proper spacing and sizing of the rings for the conductors and the equipment they will install on.

- Consider the ease of installation and whether the corona rings come with the necessary mounting hardware and instructions.

- Consider the budget available for the corona rings and find a balance between quality and cost effectiveness.

- Consider the material used to make the ring and select one that offers good, corrosion resistance and long-term reliability.

- Choose corona rings from reputable manufacturers known for producing high-quality products.

- Ensure the selected corona rings comply with relevant industry standards and regulations.

- Consider the environmental conditions the corona ring will deal with. These includes pollution, UV exposure and temperature.

Frequently asked questions

What is a corona ring as used in overhead transmission lines?

A corona ring is a device used to minimize the occurrence of corona discharge. The discharge results in energy loss, audible noise, radio interference and damage.

What are the benefits of corona rings?

By controlling and mitigating the effects of corona discharge, they offer several benefits to the high-voltage power transmission systems. These benefits include reduced energy loss, reduced audible noise, radio interference reduction, minimized equipment damage, improved power quality, optimized transmission efficiency, improved safety and cost savings.

What are the limitations of corona rings?

Corona rings have various limitations to consider before selecting for use. These limitations include maintenance requirements, spacing and clearance issues, variability, cost consideration, voltage limitations, configuration constraints and installation complexity,