A corona ring is an unique component used in high voltage electrical systems to regulate corona discharge. Corona discharge happens when there is a strong electric field gradient surrounding conductors.This causes ionization of the surrounding air, resulting in a visible glow. Corona discharge can cause power loss, electromagnetic interference and equipment damage. The rings install around high voltage components such as insulators, connections or bushings. It helps to spread the electric field gradient more uniformly. This lowers the intensity of the electric field at critical locations. It also helps to prevent the creation of corona discharge. Grading rings consist of robust and strong materials such as copper and aluminum.

Corona ring components

Corona rings have several components that work together to form a corona control system. This system, in turn, serves to manage the electric field. The components cut the effects of corona discharge in overhead transmission lines. The following are the primary components of the corona ring.

- Metallic ring – the corona ring’s fundamental components appear by its ring structure. The ring serves around high-voltage cables. The conductive materials help to regulate the electric field. It consists of materials like aluminum, copper, and other alloys.

- Insulators – these help to keep the corona ring distinct from the supporting structure. This prevents electrical current from flowing between them.

- Spacing elements – they help to maintain a specified gap between the ring and the conductor. This ensures the efficacy of corona control by spreading the electric field.

- Surface finish – corona rings undergo procedures to improve their performance, including conversion coating. This protects against corrosion, improves electrical characteristics and enhances resilience to environmental conditions.

- Support structure – the ring attaches to the support structure, keeping them at a predetermined distance.

- Mounting hardware – this includes nuts, bolts, flanges, holes, clamps, and washers for securing the corona rings.

Applications areas of corona rings

Corona rings have many different uses in the high-voltage transmission business. They help to manage and control corona discharge on transmission lines. They also improve the reliability and performance of high-voltage systems. This works by decreasing corona discharge and the resulting challenges. The corona ring’s most common applications include the following.

- Transmission lines – corona rings install on high-voltage transmission lines to control corona discharge. They aid to prevent energy loss, audible noise, radio interference, and potential equipment damage.

- Converter stations – corona rings work in converter stations to control corona discharge on transformers, bushings and other high-voltage components. This happens by dispersing the electric field gradient, preventing insulation breakdown. It also helps to increase the lifespan of transformer components, ensuring peak performance.

- High-voltage testing – the rings also aid to avoid undesirable corona discharge from the systems. This may interfere with the accuracy of the testing results. This happens by replicating corona discharge conditions, allowing researchers to investigate the impact of high voltage on materials and systems.

- Lightning arrestores – corona rings are part of the design of lightning arrestors and help to prevent corona discharge.

- Switchyards – the rings control corona discharge on a variety of equipment. This includes circuit breakers, disconnectors, and other high-voltage components.

- Wind energy – the rings manage corona effects on high-voltage components in wind turbines and generators. They enhance the reliability of the electrical infrastructure.

Choosing the Best Corona Rings

When selecting the correct corona ring, you must examine several factors to guarantee that it is suitable for your specific needs. The selected rings depend on voltage levels, ambient conditions and proposed applications. The chosen corona ring must ensure the transmission lines’ safety, dependability and efficacy. The following are some common factors to consider while choosing corona rings.

- Voltage level – choose a corona ring that can withstand the voltage level of your transmission or distribution system.

- Intended application – consider the corona ring’s intended application. Different designs can work for overhead transmission lines, substations, switchyards and other purposes.

- Ease of installation – examine how easy it is to install the corona rings and whether they include the appropriate mounting hardware and instructions.

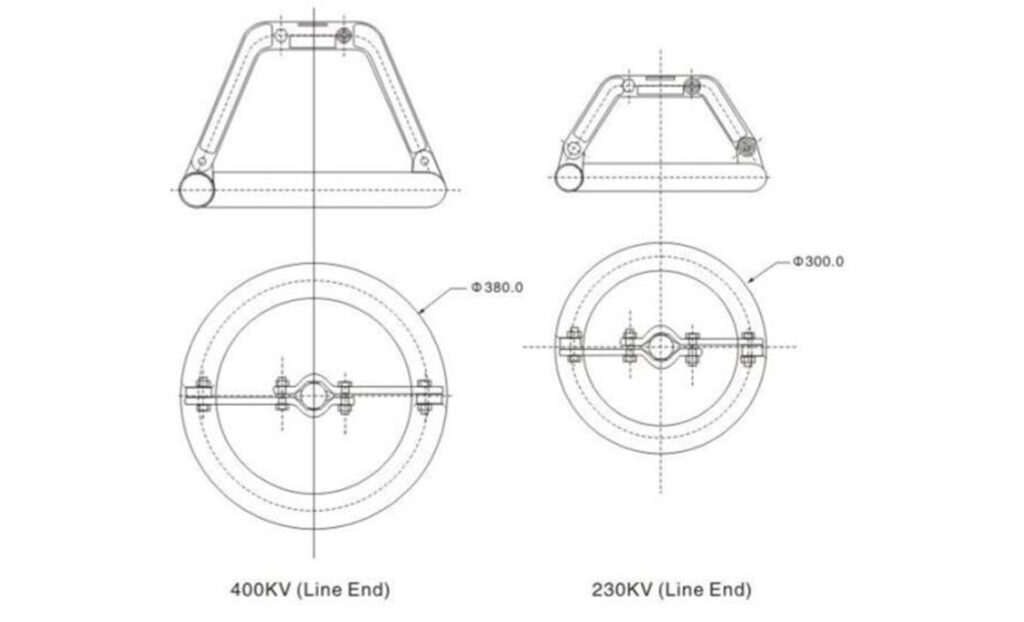

- Design and geometry – check the corona ring’s shape and geometry to confirm it is compatible with the installation position. Consider the ring shape, dimensions, mounting options and alignment needs.

- Costs – consider the cost-effectiveness of the corona rings. Strike a balance between quality and cost-effectiveness.

- Material compatibility – check the ring’s substance, such as copper or aluminum. Choose one that has strong corrosion resistance, mechanical strength and electrical conductivity.

- Surface coatings – consider any surface treatments given to the corona ring. This aims to improve its performance and durability. Common treatments include anodizing, plating, coating, and passivation.

- Manufacturer – select corona rings from recognized manufacturers known for creating high-quality and dependable products.

- Standard compliance – this entails ensuring that the corona rings chosen adhere to all applicable industry standards and regulations.

- Performance – consider doing performance testing to determine the effectiveness of the specified corona ring.

- Environmental conditions – consider the environmental parameters in which the corona ring will operate. These include pollution, UV exposure, and temperature.

Installation of Corona Rings

Corona ring installation involves several procedures to ensure proper alignment and good corona management. Additionally, follow the manufacturer’s directions to ensure that the corona control system works. This increases the efficiency and dependability of the high-voltage system. The basic installation procedure for the corona ring is as follows.

- Gather all the tools, equipment and materials required. Ensure that the components are clean and free of debris, pollutants or damage.

- Follow all safety rules, including wearing appropriate personal protective equipment. This helps to maintain workplace safety.

- Identify the locations of transmission lines, substation equipment, and other components. To ensure uniform dispersion of the electrical field gradient, the ring should set around the component.

- Clean the installation area to remove any debris, dust, grease or other pollutants that may interfere with adhesion.

- Attach the corona ring to the high voltage component using the mounting holes provided. This could entail anchoring the corona ring with bolts, screws, clamps, or other hardware. The components help to guarantee that the installation is stable and secure.

- Maintain the proper spacing and alignment of the corona ring and conductor. Ensure that the corona rings are uniformly aligned along the length of the installation. Proper alignment improves the corona ring’s performance in controlling corona discharge.

- Visually verify the installed corona rings to ensure that they align and adhere properly. Look for indicators of corrosion, misalignment or loose fasteners that could affect the ring’s effectiveness.

- Test the installations to ensure that the corona control system works properly. This includes carrying out partial discharge testing, insulation resistance measurements and other procedures. This is to verify that the high-voltage system operates as intended.

- Document the installation process including locations, date, inspection results and any relevant observations. This promotes traceability and facilitates maintenance and future inspections.

Corona Ring Maintenance Practices

Corona rings need regular maintainenance to ensure proper control of corona discharge. It also helps to spot any flaws or wear that could impede their effectiveness. A lot of factors determine the frequency with which maintenance and inspections occur. These include the operating environment, the significance of the application and the manufacturer’s guidelines. The following are some basic maintenance and inspection guidelines for corona rings.

- Inspection – conduct routine visual examinations of the corona rings. Look for indicators of physical damage, corrosion or contamination. It ensures that they are securely fastened and aligned with the components designed to protect.

- Cleaning – if there is dust, debris, or pollutants on the corona rings, use a non-abrasive cloth or a light cleaning solution to remove them.

- Fasteners tightness – check the tightness of the bolts, nuts, clamps and other fasteners used to secure the corona rings. Loose fasteners can reduce the efficiency of the corona ring.

- Replacement – this entails evaluating the quality and performance of the rings over time. Consider replacing them if there is any damage.

- Surface treatment maintenance – this includes any necessary touch-ups to the corona ring coatings. Proper surface treatment maintenance protects the corona ring from corrosion and environmental damage.

- Conduct electrical testing – this is to ensure that the corona rings are in good working order. This occurs by adhering to the approved testing protocols and frequency.

- Environmental factors – consider the ambient circumstances in which the corona rings install. This includes exposure to UV radiation, high temperatures and pollution.

- Documentation – keep detailed records of maintenance and inspection activities. This is including dates, findings and any corrective actions taken.

Frequently asked questions

Corona rings are commonly maintained through regular inspection, cleaning, fastener tightening, surface treatment monitoring, corona discharge monitoring, timely replacement, documentation of maintenance activities, and personnel training.

Take necessary corrective action if damage occurs in a corona ring during an examination. To restore functionality and integrity, the damaged corona ring may need repair or replaced, loose fasteners tightened or surface treatments recoated.