A corona ring is a device that controls the production of corona discharges around high-voltage conductors. It’s also referred to as an anti-corona ring or a graded ring. It is a toroidal-shaped metallic ring that connects to the ends of insulator strings. Corona discharge is a problem with high-voltage power lines that causes power outages. Corona discharge happens when the electric field strength surrounding a conductor surpasses the breakdown strength of the air. This induces ionization of air molecules, resulting in a bright glow around the conductor. Corona discharge can cause power outages, audible disturbances and even damage to equipment. Corona rings work by dispersing the electric field around the conductor. This is while reducing concentrated regions. This helps to decrease the detrimental effects of corona discharge. The goal is to increase the electrical system’s efficiency and dependability.

Features of the Corona Ring

Corona rings have several characteristics that make them efficient in suppressing corona discharge. It also improves the performance of high voltage systems. They have designs that reduce corona discharge and improve performance and reliability. The following are the many characteristics of the corona ring.

- Material composition – the rings are from materials with good electrical conductivity and mechanical strength. These materials include aluminium, copper and stainless steel. They also maintain the longevity and efficient conduction of electrical charges.

- Smooth surface – corona rings’ surfaces have coatings to ensure smoothness. Smoothness helps to cut localized electric field gradients. This may contribute to corona discharge.

- Sizes and dimensions – the sizes of the corona ring vary by the voltage level and the specific requirements of the electrical system. Proper size ensures the best performance in corona discharge management.

- Corrosion resistance – the rings must withstand extreme weather conditions. They thus need coatings to improve corrosion resistance.

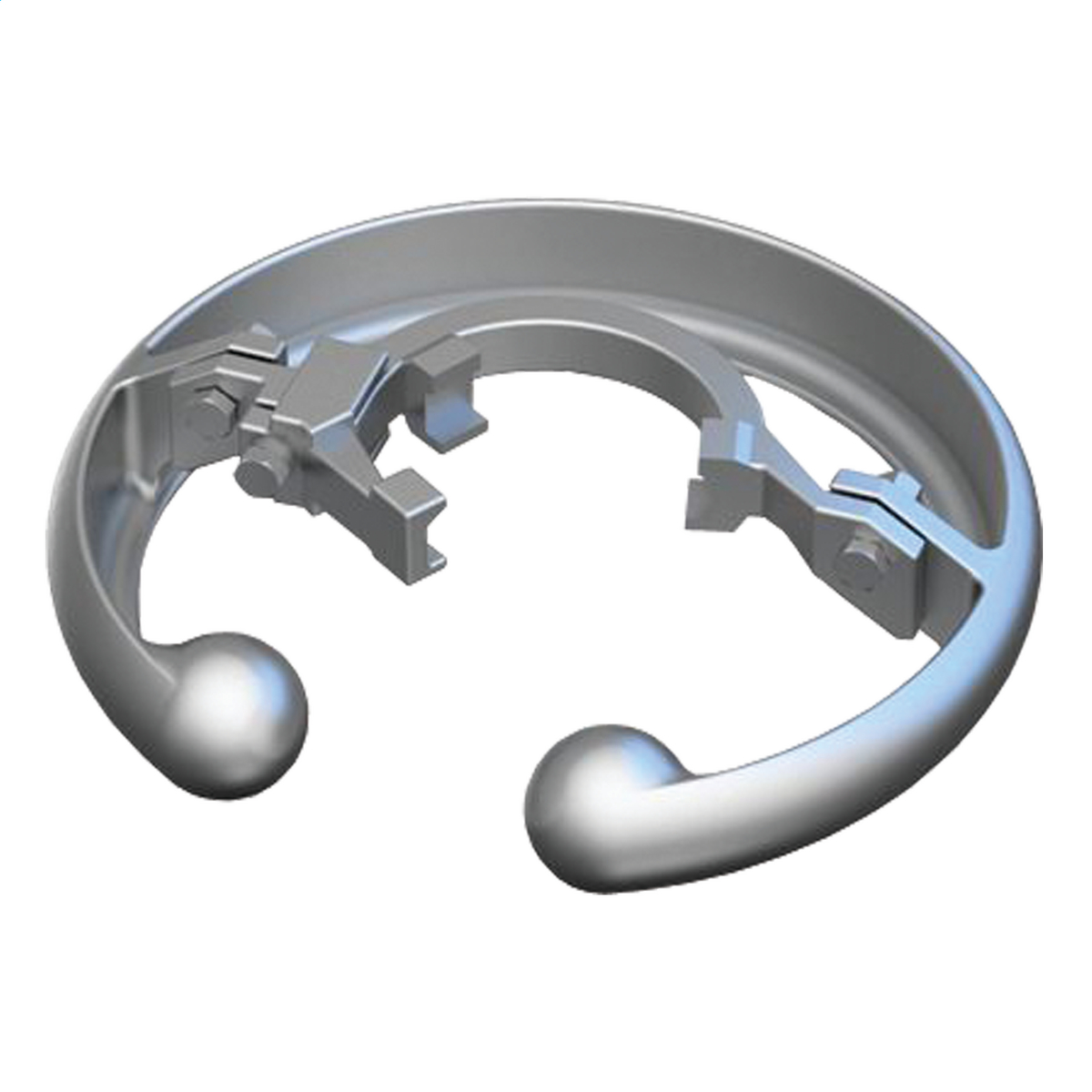

- Shape and design – the rings come in a variety of styles and shapes to suit specific purposes. They might be circular, rectangular or bespoke shapes. The form and design serve to spread the electric field around the conductor.

- Mounting mechanism – the rings have designs to be easily mounted on the ends of conductors or insulators. They may include threaded holes, clamps, or other means for secure connection.

- Aesthetic considerations – the rings feature aesthetic designs that enhance the structure’s appearance.

What is Corona and its characteristics?

Corona discharge is a phenomenon seen in high-voltage electrical circuits. This occurs when the electric field strength surrounding the conductor surpasses the breakdown strength of air. This causes air molecules to get ionized, resulting in the production of a visual discharge or glow surrounding the conductor. The following are the features of corona discharge.

- Formation – corona discharge happens when the electric field strength of a conductor surpasses a critical threshold. This causes the air molecules around the conductor to ionize. The ionization process generates a conductive route through the air. This permits current to flow, resulting in a bright discharge.

- Audible noise – the discharge produces audible noises that appear as crackling sounds. The intensity changes with the size of the electric field.

- Damage – discharge can damage equipment in high-voltage systems. The high electric field gradients can cause localized heating. It may also lead to erosion of the conductive surface and insulation breakdown.

- Visible light – the ionization of air molecules during corona discharge causes a visible glow on the conductors. This light can range from blueish-purple to reddish orange. This is depending on the conductor’s composition and voltage level.

- Energy loss – corona discharge causes energy loss in the electrical system. Energy loss can impair the system’s efficiency and result in decreased transmission capacity.

- Environmental impact – the discharge adds to ozone formation in the atmosphere. Ozone is a pollutant that has affects on both human health and the environment.

The purpose of corona rings

The primary function of the corona ring is to manage and mitigate corona discharge in high voltage electrical systems. They contribute to corona discharge regulation, energy loss reduction and equipment protection. Additionally, it is critical to engage with industry professionals for advice on the ideal corona rings for your unique requirements. The following are the primary reasons for using corona rings.

- Cut energy loss – corona discharge causes energy loss in the electrical system. Corona rings control corona discharge, reducing energy losses and increasing system efficiency.

- Increase insulation performance – the rings improve the performance of insulation systems. Corona rings serve to keep insulating materials intact and avoid premature aging.

- Reduce corona discharge – the corona ring’s principal purpose is to reduce corona discharge. Corona discharge happens when the electric field strength surrounding the conductor surpasses the breakdown strength of the air. The rings spread the electric field, reducing isolated areas of high electric field intensity.

- Prevent equipment damage – the high electric field gradients associated with corona discharge can cause localized heating, erosion, and conductive surfaces. The rings help to reduce the impact and safeguard the equipment.

- Ensure safety and dependability – corona rings prevent equipment failures and lower the risk of electrical fires and other incidents. Controlling corona discharge improves the safety and dependability of electrical systems.

Materials used to make corona rings

The material used for the corona ring depends on electrical conductivity requirements as well as mechanical strength. Manufacturers select materials that strike a balance between performance, dependability and cost effectiveness. This occurs to ensure that the corona rings work properly and last as long as possible in high voltage systems. The materials should be electrically conductive and durable. Furthermore, it is advisable to speak with professionals to determine the appropriate material for your specific use. The following are the most frequent materials used to make corona rings.

- Copper – this offers great electrical and mechanical qualities. It gives the finest electrical conduction and durability.

- Brass – this offers a blend of corrosion resistance and electrical conductivity. It is highly conductive, machinable and corrosion-resistant.

- Silver-plated copper – corona rings made of this material combine copper’s conductivity with silver’s enhanced corrosion resistance. This ensures electrical performance and durability. As a result, they are appropriate for applications requiring high reliability.

- Aluminum – this is a popular choice because to its high electrical conductivity, lightweight nature and resistance to corrosion. It is simple to manufacture and has good mechanical strength, making it appropriate for a wide range of high voltage applications.

- Stainless steel – this has high mechanical strength and resistance to moisture and chemicals. This makes them ideal for exterior installations and tough working situations.

- Composite materials – these include fiberglass-reinforced plastics. These materials provide high strength-to-weight ratio, resistance to corrosion and customizable properties.

Corona ring varieties that are commonly encountered

The corona ring comes in some styles and designs, each having its own arrangement. Each design contributes to achieving the application’s specific needs. Some factors influence the selection of the corona ring. They include voltage, setup and corona-specific issues. Each type of corona ring offers distinct advantages and tactics for mitigating corona discharge and its effects. The following are the most common types of corona rings.

- Single rings – the most common type of corona ring is single. They have a metal ring that goes around the conductor. Its aim is to balance the electric field around the conductor, preventing corona discharge.

- Flat disc corona ring – this is a flat, circular ring that fits vertically along the conductor’s axis. This produces a consistent electric field distribution.Suspension corona rings – these rings suspend beneath the high-voltage conductor. This is to ensure a uniform electric field distribution.

- Double corona rings – these consist of two rings instead of one. The inner ring is smaller than the outer one. They serve in applications where there is a high risk of corona discharge.

- Bundled conductor corona rings – these consist of two or more corona rings that bundle together to help spread the electric field among the individual conductors.

- Semicylindrical corona rings – these install around conductors to help maintain the electrical field.

- Multi-layer corona rings – these consist of up of several concentric levels of conductive materials suitable for higher voltage applications.

- Interphase spacer rings – these install between the phases of a transmission line to manage the electric field between them. This is to limit the likelihood of corona discharge between them.

- Capacitor-type corona rings – these help to introduce resistance between the conductor and the corona ring.

Frequently asked questions

A corona ring is an electrical engineering device that controls corona discharge in high voltage systems.

Corona rings serve many functions, including limiting corona discharge, lowering energy losses and improving insulating performance. They also ensure the safety and reliability of high-voltage electrical systems.

Corona rings prevent corona discharge by equally spreading the electric field around the conductor. This minimizes the number of isolated locations with a high electric field strength, which can cause corona discharge.