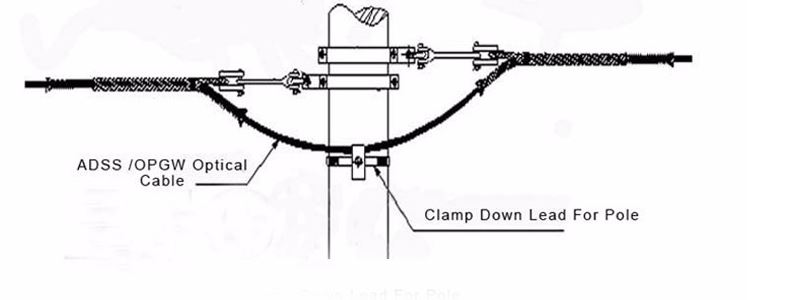

A downlead clamp is a component used in electrical and telecommunication systems to secure and support cables. Downlead clamp is also known as a downlead connector. It securely attaches the cables or downleads to their intended location. This helps prevent sagging, swaying and unintended movement due to factors such as wind, and vibration. They are from materials such as galvanized steel, stainless steel or aluminum. These materials withstand the environmental conditions of their specific application. Downlead clamps find use in various application such as transmission lines, communication cables and utility poles. The clamps maintain the stability and reliability of overhead electrical and communication systems. Southeast Asian countries consist of diverse weather conditions. This is in areas such as coastal areas, mountainous regions and dense forests. Downlead clamps play an important role in securing cables and power transmission lines. This prevents potential disruptions caused by strong winds, humidity and corrosive environments.

Key features of downlead clamp

Features and components of the downlead clamps help to ensure stability and reliability. These features can vary depending on location, design, configuration and the intended use of the clamps. Voltage-specific downlead clamps meet the diverse needs of power grid stability. They also help addresses the unique requirements of different voltage levels. The following are the key features of the downlead clamp.

- Mechanical strength – downlead clamps help to hold the weight of the cables they support. They also resist the mechanical stresses on transmission lines.

- Material – the clamps are from durable and weather-resistant materials. The materials withstand outdoor conditions and prevent corrosion.

- Design – the clamps are available in various designs and configurations. This is to accommodate different cable sizes, attachment methods and specific requirements.

- Attachment mechanism – the clamps include mechanisms for fastening the cables in place.

- Weather resistance – downlead clamps must be able to withstand the effects of weather. These include exposure to UV radiation, rain, humidity and temperature variations.

- Insulation- some clamps may need the use of insulating components to prevent electrical contact between cables. This is to reduce the risk of short circuits or other electrical issues.

Selection and installation of downlead clamp in Southeast Asia

The selection process of downlead clamps in Southeast Asia involves considering several factors. This is to ensure the selected clamp withstands the regions unique environmental conditions. This helps ensure the long-term reliability and safety of your electrical or communication system. The factors include costs, durability, ease of installation, compatibility, corrosion resistance and material used. The installation of the clamps in these regions need attention to climate and installation challenges. The following is a basic process that ensures successful and durable installation of downlead clamps.

- Ensure you have all the necessary tools and equipment needed for the installation. Adhere to safety protocols including proper grounding and protection against electrical hazards.

- Inspection the site to assess factors such as cable routes and structural integrity.

- Choose a downlead clamp suitable for the cable size, type and installation environment in Southeast Asia.

- Clear the area of any debris, obstructions or potential hazards that could hinder the installation process.

- Mark the exact locations of installations and ensure accurate measurements. This helps to maintain proper cable alignment.

- Position the cable within the downlead clamp ensuring that centers and aligns correctly.

- Attach the clamp securely to the structure using suitable hardware such as bolts, nuts and washers.

- Tighten the fasteners gradually and evenly to the recommended torque level. Avoid over tightening which could damage the clamp.

- Ensure the cable is properly positioned within the clamp without excessive tension or sag.

- Apply weatherproofing such as coatings, sealants or protective coverings. They help to shield the clamp and cable from the effects of humidity and rain.

- Inspect the installation to ensure the clamp is securely attached and aligned properly.

- Document the installation process including photographs and relevant measurements for future reference.

Maintenance and inspection of downlead clamps in Southeast Asia

Maintenance and inspection of downlead clamps ensures the continued reliability and safety. Southeast Asia consists of challenging environmental conditions which may require a proactive approach. Implement an inspection and maintenance strategy to ensures extended lifespan, reliability and safety. This helps contribute to the resilience of power transmission and communications systems. The following is a guide to maintaining and inspecting downlead clamps.

- Establish a regular inspection schedule considering the climate and usage conditions.

- Visually inspect the downlead clamps for signs of wear, corrosion, damage or misalignment

- Check for signs of corrosion such as rust spots, discoloration or pitting on the surface of the clamps.

- Periodically clean downlead clamps to remove dust, dirt and debris that could contribute to corrosion.

- Apply a corrosion-resistant lubricant to moving parts of adjustable clamps. The lubrication helps to ensure smooth operation and reduce friction.

- Regularly check and tighten fasteners following the manufacturer’s recommended torque values.

- Ensure weatherproofing measures are intact and effective in preventing moisture ingress.

- Periodically engage qualified professionals to conduct thorough inspections for critical infrastructure.

- Maintain records of all inspection and maintenance activities including dates, findings, actions taken and any replacements.

Comparative analysis of downlead clamp in Southeast Asian markets

The comparative analysis of downlead clamps involves evaluating different options available. This is because there are several options available in the region based on various factors. Create a scoring system with the collected data to rank the downlead clamp options in the market. Specific requirements of your project may also depend on the weighting of each factor. The following are the key factors in the comparative analysis.

- Brand and manufacturer – identify reputable manufacturers and brands offering downlead clamps. Research the manufacturer’s history, reputation and track record in the region.

- Voltage compatibility – compare the downlead clamps available for different voltage levels. This makes them suitable for the diverse range of electrical systems.

- Material and corrosion resistance – evaluate the materials used for the downlead clamps. This helps to confirm their resistance to corrosion in the humid and salt-exposed environments of Southeast Asia.

- Load-bearing capacity – analyze the load bearing capacity of downlead camps. This includes considering the mechanical stresses the clamps are to face.

- Adjustability and flexibility – compare the adjustability features of different downlead clamps.

- Insulation mechanisms – check the insulation mechanisms to prevent electrical contact between cables and conductors.

- Installation ease – consider the ease of installation for each option. This may include any special tools or expertise required.

Certifications and standards of downlead clamp

Certifications in Southeast Asia helps to ensure their quality, safety and compatibility with the region’s electrical infrastructure. Conduct research to confirm which specific standards are applicable in the countries of installation. This is to ensure the selected downlead clamp complies to the relevant standards and regulations. The common standards and certification for downlead clamps are as discussed below.

- IEC standards – this provides the global guidelines for design, performance and safety of electrical equipment.

- ASTM standards – this offers specifications for various materials, components and systems as used in the manufacture of downlead clamps. They provide guidance on material properties, corrosion resistance and mechanical strength.

- ISO standards – ISO standards relates to electrical equipment, materials and safety to ensure international best practices.

- European Norm standards – these are the standards related to electrical and mechanical components. They help to ensure products meet quality and safety requirements.

- Local electrical codes and regulations – Southeast Asian countries have their own national electrical codes that downlead clamps must follow.

Regional markets for downlead clamps in Southeast Asia

The regional market for downlead clamps in Southeast Asia is dependent on the diverse economies and growing infrastructure needs. The growing demand for downlead clamps in Southeast Asia is from several factors discussed below.

- Undergoing rapid urbanization and industrialization in the countries, lead to the increased demand for reliable power transmission and communication infrastructure.

- The need for efficient power transmission systems to meet increasing energy demand is propelling investments in downlead clamps.

- Expanding telecommunication networks require robust downlead clamps to ensure uninterrupted connectivity.

- The humid and tropical climate necessitates downlead clamps that can withstand corrosion, humidity and the mechanical stresses of extreme weather.

- Coastal areas need corrosion-resistant downlead clamps. They help to withstand the corrosive effects of salt-laden air.

- International investments and collaborations in infrastructure projects drive the adoption of standardized and reliable downlead clamps.

- Increased focus on renewable energy sources demand downlead clamps. This is for connecting solar panels and equipment to power distribution networks.

- The growth of networks such as 5G deployment drives the needs for downlead clamps. They help to support, secure and stable cable installations.

Frequently asked questions

What is a downlead clamps?

A downlead clamp is a component used in electrical and telecommunication systems. They secure and support cables that run vertically from an overhead line or structure to the equipment.

What are the key considerations when selecting downlead clamps?

When selecting downlead clamps, consider factors such as voltage compatibility, corrosion resistance, load-bearing capacity, insulation requirements and adjustability among others.

How long do downlead clamps last?

The lifespan of downlead clamps vary depending on factors such as the quality of materials, environmental conditions and maintenance practices. high-quality downlead clamps can last for may years when properly maintained.