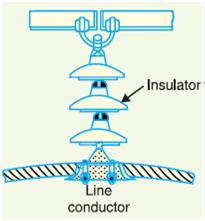

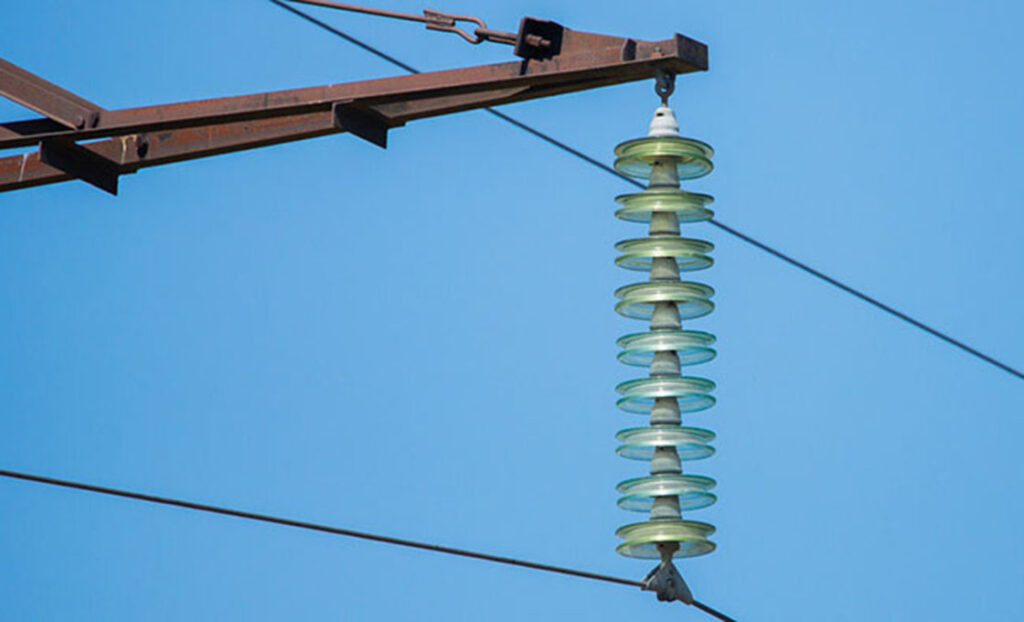

A suspension insulator is a device used to support and insulate the conductors from the supporting structures. They are also known as string insulator or a line insulator. It also helps to maintain the electrical isolation and mechanical integrity of the power lines. Suspension insulators have a design that withstands environmental conditions. It also ensures the safe and efficient transmission of electricity. They are from materials such as porcelain, glass or composite materials. These materials and design allow them to tackle extreme weather conditions common in Southeast Asia. They find use in applications such as high voltage transmission lines, distribution lines, substations, HVDC transmission and river crossings.

Key features of suspension insulator

The features work together to enable suspension insulators to provide the electrical insulation and mechanical support. They also ensure the safe and efficient transmission of electricity over long distances. The choice of suspension insulator depends on the voltage levels, environmental conditions and system requirements. The following are the key features of the suspension insulator.

- Material – they are from high-quality insulating materials. These materials include porcelain, glass or composite materials.

- Stacked design – suspension insulators have a number of stacks. They depend on the voltage level and insulation capability.

- Mechanical strength – they have mechanical strength to withstand mechanical stresses and loads. They provide support to the conductors and maintain the integrity of overhead lines.

- Shedding design – common designs such as bell-type or disc insulators have sheds. These help in shedding contaminants, moisture and pollutants.

- Corrosion resistance – the materials enable them to resist corrosion, chemical attack and the effects of weather.

- Easy installation – they have fittings and hardware that allow for safe and secure attachment to conductors.

- Voltage rating – they are available in various voltage rating to suit different applications in the industry.

- Creepage distance – this is the distance along the surface of the insulator between two energized parts. The appropriate creepage distances prevent electrical arcing and flashovers.

- Weight and size variability – the different sizes and weights accommodate different conductor sizes and mechanical load requirements.

Selection and installation of suspension insulator

Proper selection of the suspension insulators ensures the safe and reliable performance of the transmission line. Additionally, it is advisable to consult with industry experts for guidance on the selection. This ensures the proper selection of an insulator that best suits your application need. The factors include cost, corona performance, reliability, creepage distance, mechanical loads and voltage level. The installation process should ensure the safe and reliable operation of the electrical system. The following is a basic installation guide for the suspension insulator.

- Safety precautions – ensure you have all the safety equipment such as gloves, helmets and safety glasses.

- Inspection – inspect all suspension insulators for any visible defects, damage or contamination.

- Preparation – ensure that the work area is clear of obstructions and hazards.

- Rigging and lifting – use mechanical equipment like cranes to lift the insulators into position. Rig the insulators securely using suitable slings and hooks.

- Mounting insulator – attach the insulators to the conductor and ensure proper alignment. Inspect and tighten all fittings and hardware following the manufacturer’s torque specifications.

- Tensioning – tension the conductors to the appropriate levels. This is by ensuring correct positioning of the insulators.

- Creepage distance and spacing – ensure the insulators are correctly spaced along the conductor. This helps to provide the required creepage distance.

- Cleaning – clean the insulator surfaces to remove any dust, dirt or contaminants. The contaminants may affect their electrical performance.

- Final inspections – conduct a final inspection of all installed suspension insulators. This is to verify they are properly installed, aligned and tensioned.

- Documentation – keep detailed records of installation process. This includes insulator serial numbers, inspection results and any deviations from the installation plans.

Maintenance and inspection of suspension insulator

The insulators require regular maintenance to ensure the continued reliability and performance. It also helps identify and address issues before hand. It also helps reduce the risk of insulator failure and electrical outages. Early detection can prevent costly downtime and service disruptions. The following is a basic guide on maintenance and inspection of suspension insulators.

- Establish a maintenance schedule that includes regular inspections and cleaning. This depends on the industry standards, environmental conditions and historical performance data.

- Visually inspect all suspension insulators for signs of damage, contamination or defects. Check for cracks, chips or physical damage to the insulator units.

- Remove any dirt, dust or contamination from the insulator surfaces.

- Assess the level of contamination on the insulators and use pollution severity charts or instruments to determine.

- Verify the insulator strings are properly aligned with the conductor and supporting structures.

- Check the tension of the conductors and verify that it falls within the recommended range.

- Keep detailed records of inspection results including photographs, date and personnel involved.

Comparative analysis of suspension insulator in Southeast Asia

A comparative analysis includes comparing and contrasting the designs and prices of suspension insulators in the market. Some of the common factors include unique environmental, climatic and operational conditions of the region. The following is analysis of suspension insulators in the Southeast Asian market.

- Material composition – materials such as ceramic and composite make them adaptable to lower medium voltage lines common in Southeast Asia.

- Pollution resistance – pollution resistant insulators are mostly suited to high humidity and pollution levels in Southeast Asia.

- Mechanical strength – composite and polymer insulators provide strength due to their lightweight factors. This helps to reduce the stresses on support structures.

- Corrosion resistance – they have corrosion-resistant which make them suitable for such environments.

- Cost-effectiveness – balance the cost and quality of the suspension insulators.

- Industry trends – Southeast Asian market is shifting towards composite and polymer insulators. This is due to their advantages in pollution resistance and mechanical strength.

- Environmental impact – the various insulator materials such as composite and polymer may raise environmental concerns.

- Ease of installation – select insulators that are easy to install and maintain due to the various factors in Southeast Asia.

Certifications and standards in Southeast Asia

There are various standards and regulations related to suspension insulators in southeast Asia. These standards help ensure their quality, performance and safety in electrical transmission and distribution applications. The standards may be international, regional and national certifications. The following are the common standards and regulations for insulators in Southeast Asia.

- International Electrotechnical commission (IEC) – these standards provide the characteristics of insulator, definitions, test methods and acceptable criteria.

- ASTM international – these standards offer guidelines on the test method for corrosive of electrical insulating materials.

- Regional standards – these include ASEAN standards related to electrical equipment and insulators.

- National standards – each country have their own national standards and regulations governing the use of suspension insulators.

- ISO – these standards demonstrate their commitment to quality management systems.

- IEC conformity assessment scheme – these include assessment services and certification scheme. This is to ensure electrical products meet international safety and performance standards.

Regional market for suspension insulator in Southeast Asia

The regional market for suspension insulators in Southeast Asia is from various factors in the market. There are also other various factors that influence the market. These include diverse landscape, developed urban areas and challenging environmental conditions. These factors may also affect the demand of the suspension insulators in the market. Additionally, the manufacturers must adapt to these market dynamics. They should also offer solutions tailored to the specific needs of the region. The following are the factors that shape the market for suspension insulators in Southeast Asia.

- Expanding electrical grid – investments in expanding and their electrical grids lead to increased demand.

- Renewable energy integration – this is the increased adoption if renewable energy sources. This also leads to increased demand of suspensoin insulators.

- Urbanization and industrialization – this drives the need for reliable electricity supply in urban and industrial areas.

- Pollution challenges – high level of pollution leads to increased demand for pollution-resistant insulators.

- Cost-effectiveness – the increased demand may also influence the cost of the insulators in the market.

- Government initiatives – these improve the energy efficiency and grid reliability in the countries. They should also align with the international standards and certifications.

- Private sector investment – the involvement of private sector also drives the infrastructure development. It also increases the adoption of modern insulator technologies.

- Local manufacturing – the increased manufacturing influences the pricing and supply of insulators.

- Certifications and standards – the insulators should comply with the standards. This is to ensure the quality and safety of insulators.

Frequently asked questions

What is a suspension insulator as used in overhead transmission lines?

Suspension insulators are electrical components used to provide electrical insulation between the conductor and supporting structure. It does this while supporting the conductor’s weight on the overhead transmission lines.

Which types of insulators is better for the coastal regions in Southeast Asia?

Composite materials are corrosion resistant and offer good pollution performance in the coastal regions. They are also lightweight which reducing the mechanical load on supporting structure.

What are the maintenance practices that help extend the lifespan of suspension insulators in Southeast Asia?

Regular inspections, cleaning and monitoring of pollution levels are the common maintenance practices for suspension insulators.