A stay insulator is a type of insulator used on low voltage transmission lines. it is also known as a guy insulator or egg insulator. Stay insulator prevent electrical current from flowing along the guy wires. It keeps the structure electrically isolated from the ground. A guy wire is a tensioned cable used to stabilize utility poles and towers. It is from materials like high-quality porcelain or toughened glass. These materials provide electrical insulating properties and are able to withstand harsh conditions. Its structure resembles a cylindrical or cone-shaped design with metal fittings. It consists of a ceramic or composite insulator with fittings at each end for attachment to the guy wire. Stay insulators act as silent guardians in the electrical grid. They ensure the safe and reliable operation of the system. Stay insulators prevent electrical leakage and ensure proper grounding.

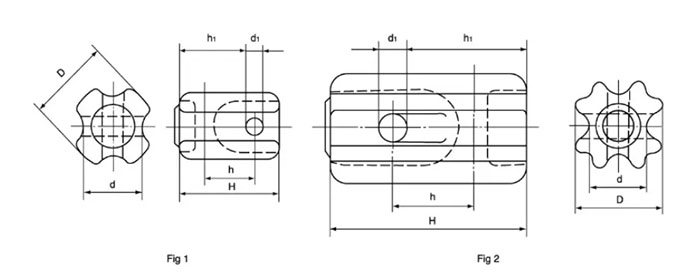

Desing and structure of stay insulator

The design of the stay insulator varies depending on its intended application among other factors. Their design helps to provide reliable electrical insulation, mechanical strength and long-term durability. The following is a basic design and structure of the stay insulator.

- Insulating material – stay insulators are from materials with high electrical insulation properties. These include porcelain, glass or composite materials like polymer. The materials are also able to withstand high electrical voltages.

- Core – they have a hollow core that provides mechanical strength and stability to the insulator. It has designs to resist compression, tension and bending forces.

- Outer shell – the core has an outer shell made of the same insulating material. This shell provides extra protection against environmental factors. This is including moisture, dirt and UV radiation.

- Fittings – stay insulators have end fittings for attachment to the guy wire and the supporting structure. The fittings are from metal and may include threaded studs, clevises or other hardware.

- Design features – some of the insulators may have extra design features like ribs or sheds. They help to increase mechanical strength and shed improve electrical performance.

Common features of a stay insulator

The main purpose of the stay insulator is to provide mechanical support and electrical insulation to guy wires. Stay insulators ensure the safe and efficient operation of electrical lines. The following are the common features of the stay insulators.

- Electrical insulation – the insulators have designs to prevent electrical current from flowing along the stay wire. The insulation helps to maintain the integrity of the electrical distribution to prevent power loss.

- Environmental resistance – stay insulators are able to withstand moisture, UV radiation, pollution and temperature variations. This helps them to maintain their performance over long periods without degradation.

- Pollution performance – the insulators are mostly installed in areas with high levels of pollution. Features like sheds, skirts or hydrophobic coatings help to mitigate the effects of pollution.

- Mechanical strength – the insulators must withstand mechanical stresses such as tension and compression. They help to support the weight of the structure and resist wind loads, vibrations and other forces.

- Corrosion resistance – stay insulators also face corrosive elements in the application area. This is including salt spray, industrial pollutants and chemicals. They help protect against rust and corrosion to ensure longer service life.

- Easy installation and maintenance – the insulators should have designs that allow easy installation and maintenance. This is to reduce downtime and labor costs. They also feature standardized fittings and mounting options for secure attachment.

- Compliance with standards – stay insulators should follow relevant industry standards and regulations. This is to ensure safety, reliability and interoperability.

Differences between a guy insulator and a strain insulator

Stay insulators and strain insulators both work in electrical power systems for different purposes. They also have distinct designs for differentiation. They both provide insulation and support in different applications. Additionally, it is advisable to consult with experts whenever in doubt. The following are the major differences between the stay insulator and strain insulator.

- Purpose – stay insulators provide electrical insulation and mechanical support to guy wires. They stabilize utility poles, transmission towers or similar structures. They ensure the structure remains electrically isolated from the ground. Strain insulators help to support and insulate electrical conductors. They help maintain proper spacing and alignment of conductors to prevent electrical arcing.

- Application – stay insulators install at attachment points of guy wires to structures. They work in overhead power distribution and transmission lines. strain insulators install at intervals along the electrical conductors to provide mechanical support. They find use in overhead power transmission and distribution lines.

- Design – stay insulators have designs to withstand both electrical and mechanical stresses. They have fittings at each end for attachment to guy wires and support structures. Strain insulators are able to handle mechanical tension or strain along electrical conductors. The insulator has specific shapes to accommodate the mechanical loads from the conductor.

- Functionality – stay insulators provide electrical insulation to prevent current leakage along the guy wires. They also provide mechanical support to withstand wind loads and other external forces. Strain insulators provide mechanical support to electrical conductors under tension. They distribute mechanical loads along the length of the conductor. They also help maintain proper conductor alignment.

Types of stay insulators

There are different types of stay insulators used on the power transmission lines and distribution lines. They each have unique designs and features unique to the type of application. common types of stay insulators vary depending on voltage rating and mounting style. The following are the main types of stay insulators used on the transmission systems.

- Angle stay insulators – these insulators work at the angled sections of the guy wire where they change direction. They help maintain the necessary clearance between the guy wire and the support structure. This is while withstanding the mechanical forces exerted on the angle point.

- Hybrid stay insulators – these insulators combine different materials such as porcelain, glass and polymers. These insulators balance of properties suitable for various applications.

- Suspension Stay insulators – these are the most used type of insulators. It’s design features a long cylindrical insulator body and metal end fittings.

- Non-ceramic stay insulators – non-ceramic stay insulators are from composite materials or polymer. They offer benefits like lightweight construction, high pollution resistance and excellent mechanical properties.

- Strain Stay insulators – these are also known as tension stay insulators. They have designs to handle high mechanical loads. This is especially in locations where the guy wires experience tension or strain.

- Insulated stay rods – insulated stay rods work in specific applications where the entire length of the guy wire needs insulation. They have a solid or hollow rod made of insulating material for attachment to the support structure.

- Clevis-type stay insulators – these have a U-shaped body with a pin that goes through the stay wire.

- Vibration dampening stay insulators – these are also known as vibration control or anti-vibration stay insulators. They help to reduce the vibrations of oscillations of the guy wire caused by winds or other factors.

Applications of the stay insulators

Stay insulators work in various scenarios in electrical power systems and other industries. This is including applications in need of mechanical support and electrical insulation. They help to ensure the safety, stability and efficiency of various structures and systems. the following are the common application areas of stay insulators.

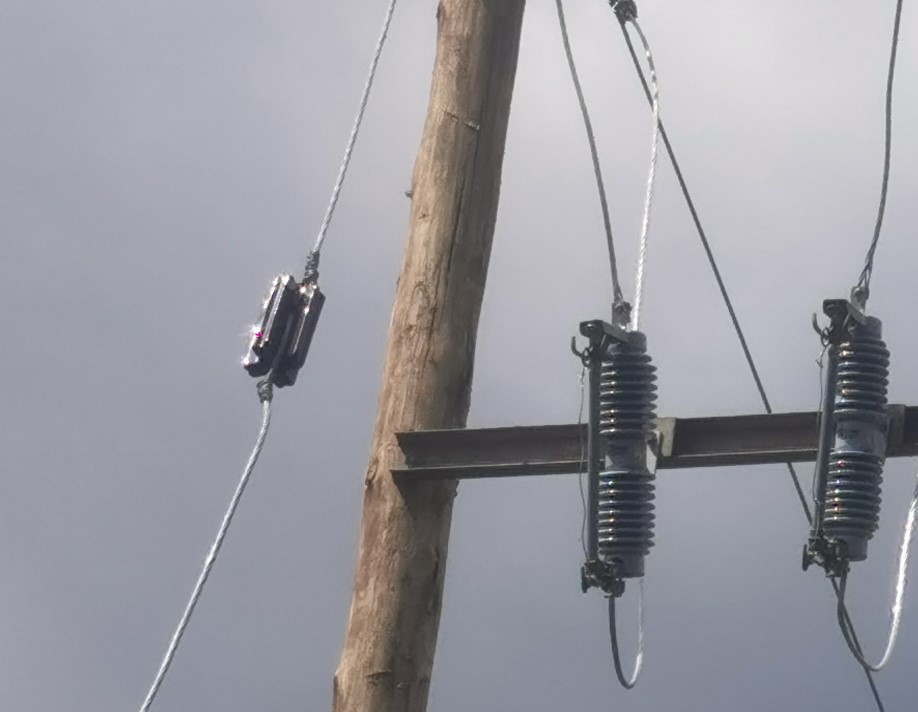

- Transmission towers – stay insulators help to support and insulate guy wires attached to utility poles and transmission towers. They provide support to stabilize the structure.

- Overhead transmission lines – the insulators install at the attachment points of guy wires along the overhead lines. They help maintain the proper tension and alignment of the conductors.

- Telecommunication lines – the insulators work in the construction of telecommunication towers and antennas. This is to support and insulate guy wires used for structural stability.

- Railway electrification systems – they also work in railway electrification systems to support the overhead catenary wires. They also provide electrical insulation between the wires and the supporting structures. Stay wires also help maintain the proper tension and alignment of the catenary wires to ensure reliable train operations.

- Wind turbine towers – stay insulators work in the construction of wind turbine towers to insulate guy wires. They help withstand wind loads and vibrations while ensuring electrical safety and reliability.

- Structural construction – they also find use in structural construction projects where guy wires provide structural bracing. They provide mechanical support in bridges, towers and industrial structures.

- Antenna towers and broadcast towers – the insulators work in the construction of antenna towers, broadcast masts and other structures. They help to prevent interference with radio frequency signals.

Frequently asked questions

A stay insulator is a component used in electrical systems to provide both electrical insulation and mechanical support. They install at the attachment point of guy wires to utility poles or transmission towers.

Stay insulators are from insulating materials such as glass, porcelain or composites. These materials help to prevent electrical current from travelling along the guy wires. They also offer high electrical resistance to isolate the supported structure from the ground.

Consider voltage rating, mechanical load requirements, environmental conditions and pollution performance.