An alley arm is a metal bracket commonly used on power transmission lines to support and protect electrical distribution. It protects equipment such as transformers and insulators. An alley arm is also known as an alley arm brace. It is also used to support a crossarm that is not balanced properly on a power pole or structure. Alley arms helps to improve the physical appearance of power lines by reducing sagging and twisting. The alley arms brace provides a secure and stable platform for mounting equipment. This reduces the strain on power pole and minimizes the risk of damage to the equipment. Alley arms are mostly made of sturdy materials such as steel, aluminum or other materials with high strength and durability.

Components of the alley arm

Several reputable manufacturers and suppliers in the market offer a wide range of alley arms used for different applications in the power lines. They also come with different designs and components that work together to offer the best support and stability. Below are some of the key components of the alley arm brace.

- Bracket – the main component of the alley arm from steel designed to provide support to the power pole. It spreads outward from the power pole at an angle which creates a platform for mounting electrical equipment.

- Crossarm – this is the level beam attached to the arm bracket which provides additional support for mounting electrical equipment. It is mainly made from wood or composite materials with insulating properties.

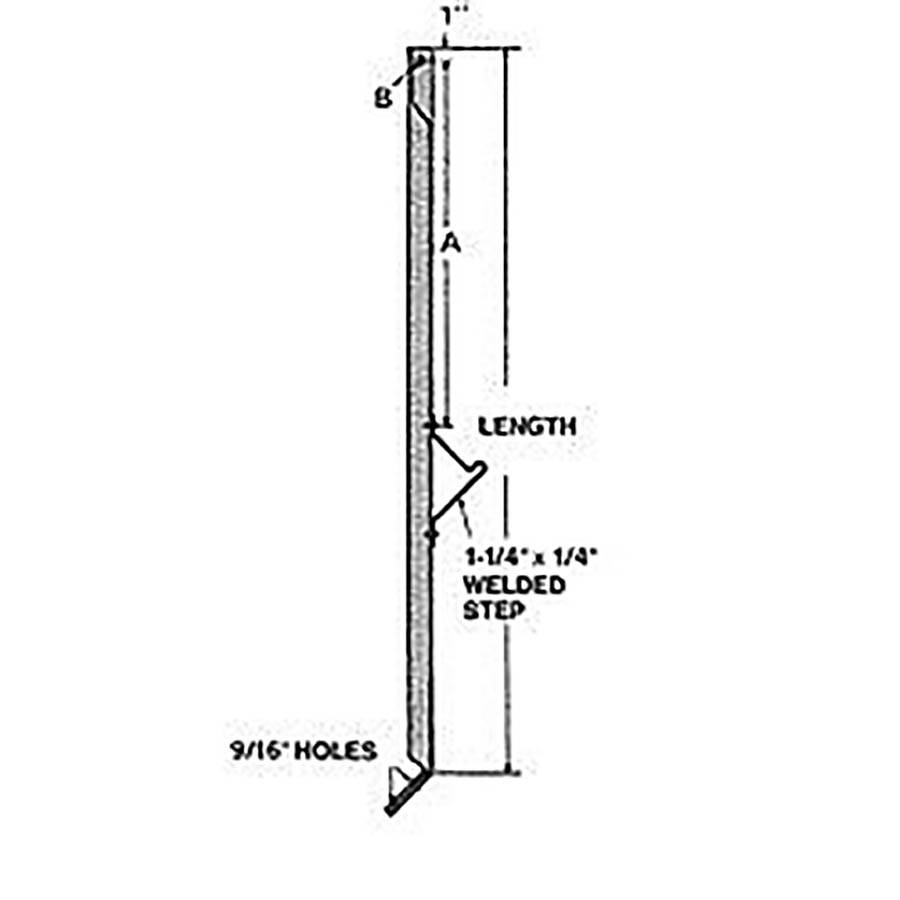

- Holes – the bracket and crossarm have pre-drilled holes for secure attachment and mounting of electrical components. The holes also allow for easy installation and adjustment of equipment on the alley arm.s

- Fasteners – fasteners such as bolts, nuts and washer secure the components of the alley arms.

- Insulators – insulators may incorporate into the alley arms assembly to provide electrical insulation. They also prevent current leakage between the equipment and the arm structure.

Types of alley arm

The type of alley arm for a specific installation depends on the specific requirement and equipment space requirements, environmental conditions and regulation and standards. Different manufacturers and suppliers also provide different designs that may work in different applications in the industries. The following are the commonly used types of alley arms.

Single alley arms – this is the most basic type of alley arm that consists of an arm bracket and crossarm configuration. Single alley arm can only support a singe crossarm and are simple to install and maintain.

Offset alley arms – offset alley arm has an angled configuration which allows for mounting equipment to extend further away from the power pole.

Double alley arms – this alley arm features two arm bracket and crossarms. The arms allow for the installation of multiple sets of electrical equipment on both sides of the power pole. This makes them more adaptable than the single-alley arms.

Elongated alley arms – this alley arm has a design that gradually decreases the width along the length of the arm bracket or crossarm. The shape also provides additional strength and reduces wind resistance. This makes them suitable for areas prone to high winds.

H-frame alley arms – these have a H-shape and designed to support heavy loads on the power poles. They are strong than the other types of alley arms which makes them more complex to install and maintain.

Applications of alley arm

There are different types and designs of alley arms that enable them to work in various applications in the industry. Alley arms are versatile and flexible which makes them vital components for efficient equipment mounting, clearance management and system expansion in electrical infrastructure. The following are the common applications of alley arms.

- Alley arms work on power lines to support crossarms and wires on a power line. They also help to prevent the crossarms from sagging or twisting. Additionally, alley arms provide a platform for mounting electrical distribution equipment such as transformers, switches, insulators and arrestors.

- They also support communication lines such as telephone and internet lines for efficiency and reliability. This is by providing a mounting point away from the pole to help separate and establish the cables.

- Alley arms support street lights mounted on crossarms to prevent sagging and twisting. Crossarms work in the mounting of street lights which support the street light.

- Alley arms brace support signage such as traffic lights and street signs. Signage used for these purposes are larger than power lines which requires the most basic alley arms for support.

- The arms are also used for temporary installations where the equipment needs to mount for testing, maintenance and emergency situations.

Alley arms installation guide

Specific installation steps depend on the manufacturer’s guidelines and instructions. It also depends on the design and the type of installation. It is always advisable to consult with professionals and experts in the industry to ensure safe and proper installation. The following are the common steps involved in the installation of the alley arms.

- Gather all the necessary tools and including the alley arm, mounting hardware, fasteners and ensure that the work area is clean and free from blocks.

- . Determine the appropriate location on the power pole for installing the alley arm by considering factors such as clearance requirements, equipment spacing and alignment with the power lines. also, align the alley arm against the power pole at a right angle which ensures that the arm bracket aligns vertically with the pole and crossarm.

- Mark the mounting hole locations on the power pole and ensure the markings match with pre-drilled holes on the arm bracket.

- Use suitable drill and drill more to create trial holes at the marked locations on the power pole. Attach the arm bracket to the power pole using the appropriate fasteners and tighten them securely.

- Position the crossarm on the arm bracket aligning the pre-drilled holes on the crossarm with the corresponding holes on the bracket. Also, insert the fasteners through the holes and tighten them securely to secure the crossarm to the bracket.

- Mount the desired electrical equipment onto the crossarm following the manufacturer’s instructions.

- Inspect the installation to ensure that all connections, fasteners and equipment mountings are secure and properly aligned. Visually inspect the installations to check for signs of damage.

Selecting the best alley arms

The selection process of the alley arm involves various factors to meet the specific requirements of the application. When in doubt on which alley arm to select, you should consult with experts on the electrical industry for advice and guidance. The following are the key factors to consider when selecting the best alley arm.

- Consider the initial cost of the alley arms and balance between functionality and quality. The selected alley arms should prioritize the reliability of the alley arm to ensure long-term performance.

- Ensure that the selected alley arm meets the related industry standards, regulations and safety codes.

- Study the durability, strength and corrosion resistance of the material based on the environmental conditions.

- Assess the load capacity of the alley arms to ensure it can support the weight and size of the equipment to mount.

- Select an alley arm from a reputable manufacturer who should have a track record in producing high-quality and reliable products.

- Evaluate the design and configuration of the alley arm and consider aspects such as ease of installation, adjustability and compatibility with the existing power poles.

- Determine the required clearance and spacing between the power pole and equipment.

Frequently Asked Questions

What is an alley arm as used on power transmission lines?

Alley arms prevents the crossarm from sagging or twisting which could cause damage to the wires and cause an outage. Alley arms provides a secure and stable platform for mounting equipment which reduces the strain on the power pole.

What are the common types of alley arms?

Arm bracket – main component of the alley arm designed to provide support and secure attachment to the power pole.

Crossarm – this attaches to the arm bracket to provide additional support for mounting electrical equipment.

Holes – pre-drilled holes for secure attachment and mounting of electrical components.

Insulation – insulators provide electrical insulation and prevent electrical current leakage between the equipment and the arm structure.

What are the benefits of alley arms?

Easy accessibility and maintenance

Structural support

Safety and reliability

Flexibility and expansion

Equipment mounting

What are the limitations of using alley arms?

Weight limitations

Space constraints

Limited adjustability

Compatibility with existing infrastructure

Installation complexity

High initial costs