An apparatus used to manage aeolian vibrations in ADSS cables is a spiral vibration damper. Fiber optic cables intended for aerial installations are also known as ADSS cables. Over time, aeolian vibrations may cause weariness and even injury. These vibrations happen by oscillations in the wind and other external factors. To lessen vibrations and load on the cable, dampers install along its whole length. A metallic rod with a helical shape that is periodically fastened to the cable makes up the spral vibration damper. The spiral design lessens the vibrations’ amplitude and aids in obstructing the wind flow around the cable. ADSS cables have reliable performance and an extended lifespan by controlling these vibrations. Power transmission and telecommunication lines use spiral vibration dampers.

Characteristics of a spiral vibration damper

Aeolian vibrations can be effectively controlled by spiral vibration dampers for ADSS cables due to some benefits. Together, these characteristics help ADSS cables reduce aeolian vibrations. Additionally, they support dependable operation in outdoor settings. The different characteristics of spiral vibration dampers are as follows.

- Material composition – the dampers manufacture from strong materials like steel or aluminum alloy. This contributes to longevity and durability in outdoor settings.

- Mechanism of attachment – the dampers help connect to the ADSS cable on a regular basis. They might include devices for a safe and dependable installation such as clamps.

- Resonance frequency – they have resonance frequencies that are in tune with the cable system’s inherent frequency. This serves to dissipate the energy from the vibrations of the cable and guarantee optimal damping performance.

- Maintenance – to make sure the dampers attach and work as intended, they must undergo inspection on a regular basis. This examination is part of the regular cable maintenance routine.

- Spiral design – the spiral design serves to obstruct the wind’s path around the cable. This lessens the amplitude of the cable vibrations and helps to create turbulence.

- Weight – the damper’s weight contributes to efficient damping without placing an undue strain on the cable. The balancing lowers vibration amplitudes while guaranteeing the cable stays supported.

- Weather resistance – the dampers can tolerate a range of weather circumstances. This covers strong winds, precipitation, snowfall and sun exposure. This is to guarantee outdoor installations’ long-term dependability and performance.

Material limitations for spiral vibration damper construction

Aeolian vibrations in ADSS cables operate using spiral vibration dampers without causing any harm. Materials are a major factor in spiral vibration dampers’ longevity and performance. The efficacy, longevity and performance of the materials vary by their limitations. A proper selection takes into account variables including cost, sustainability, mechanical needs and environmental conditions. The materials utilized have the following limitations.

- Corrosion resistance – when exposed to moisture or salt, certain materials, like steel or aluminum, may corrode. The efficiency of the dampers may reduce by corrosion. Additionally, corrosion could risk the structural integrity.

- Mechanical strength – the dampers’ ability to bear the strains caused by wind loads depends on their mechanical strength. Insufficient mechanical strength results in damage to cables and impairs the dampening effect.

- Environmental impact – take into account elements like recycling potential, manufacturing energy usage and resource depletion. These elements affect the material’s environmental sustainability.

- Installation and maintenance -certain materials need specialized installation methods. This includes materials that need extra effort or equipment for installation or that are challenging to weld.

- UV degradation – over time, materials like plastics and polymers deteriorate due to exposure to UV radiation. Failure, discolouration and a loss of mechanical strength result from this.

- Temperature sensitivity – certain materials exhibit variations in mechanical characteristics in response to temperature changes. Low temperatures can cause some plastics to become brittle, which impairs their ability to absorb sound.

- Costs – one limiting factor may be the price of the materials required to make dampers. Higher-priced materials may have characteristics like strong corrosion resistance.

ADSS cable spiral vibration dampers

Wind-induced aeolian vibrations decrease in ADSS cables with the application of spiral vibration dampers. The dampers serve to lessen the vibrations’ amplitude and to obstruct the wind flow surrounding the cable. For efficacy, it’s also critical to guarantee appropriate material selection, design, and upkeep. The salient features of spial vibration dampers for ADSs cables are as follows.

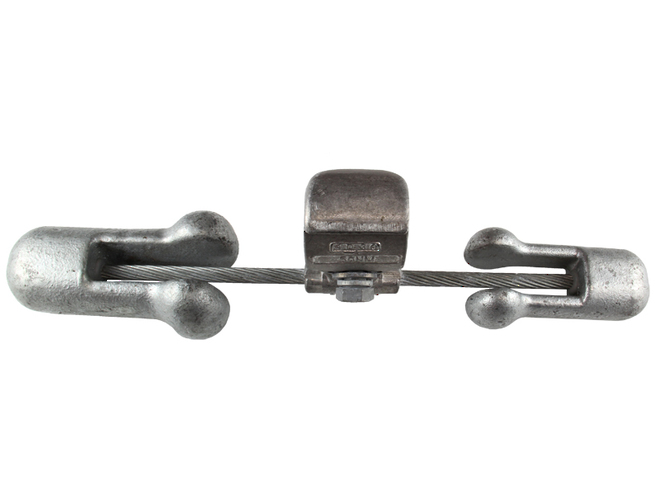

- Design – the dampers come out of a metallic rod with a helical shape that is periodically fastened to the ADSS cable. This form aids in creating turbulence in the wind flow, which serves to disperse the vibrations’ energy.

- Installation – during installation or as part of routine maintenance, the dampers install on the ADSS cable. To guarantee correct alignment and efficacy, they attach to the cable using clamps or alternative means.

- Effectiveness – within a specific frequency range, SVDs aid in the management of aeolian vibrations. To provide the best damping performance, they also have designs that correspond with the cable system’s resonance frequency.

- Environmental factors – spiral vibration dampers are set to endure a variety of environmental circumstances. This covers strong winds, precipitation, snowfall and UV rays. They support outdoor installations’ consistent performance.

- Material – high-strength and corrosion-resistant materials make up the dampers. In outdoor settings, they contribute to longevity and durability.

- Spacing – the distance between spiral vibration dampers throughout the ADSS cable’s length depends on some variables. These include the required damping performance, wind conditions and cable diameter.

- Maintenance – to guarantee correct attachment and operation, spiral vibration dampers may need a recurring examination.

ADSS cable accessories that pair with Stockbridge dampers

Spiral vibration damper work with a variety of accessories to maximize their performance. Additionally, they guarantee the durability and stability of ADSs cables. It’s also a good idea to consult an expert for advice on which accessories are best for your application. Here is a discussion of a few of the accessories.

- Dead ends – these aid in anchoring ADSS cables to sustain tall objects like towers or poles. To stop excessive movement, they also make sure the wires are properly tensioned.

- Cable Stockbridge dampers– these dampers sit along the ADSS cable at predetermined intervals. This is to further reduce aeolian vibrations. A weight hung on a cable loop serves as the damper’s primary component, absorbing and dispersing vibration energy.

- Anti-galloping devices – these operate in regions where high-amplitude, low-frequency motion is common, such horse galloping. They lessen the chance of damage and aid in stabilizing the cables.

- Hardware for mounting – brackets, washers, nuts, bolts and washers serve to fasten the dampers. They support the ADSS cables’ supporting structures. Hardware that is the right size helps to guarantee the stability and effectiveness of the accessories.

- Preformed line products – these help to make installing spiral vibration dampers on ADSS cables easier. They guarantee correct alignment along the whole length of the cable and offer a safe attachment point for the dampers.

- Monitoring systems for vibration – these systems fit all the way down the ADSS cable. They support real-time vibration analysis and detection. The systems offer useful information for maximizing the damper’s location and efficiency.

- Materials for weatherproofing – they are coatings, tapes or wraps that shield the dampers from the elements. This ensures dependable operation and increases the accessories’ longevity.

Updates and developments in the industry for spiral vibration damper

The spiral vibration dampers employed in ADSS cables have led to some industry advances. They are a reflection of the continuous efforts made by the sector to enhance the functionality, dependability and sustainability of dampers. Seeking advice on the latest developments from industry professionals is also a good idea. The developments and trends in spiral vibration dampers are as follows.

- Material innovation – this is the creation of novel materials with enhanced qualities as a result of advances in material science. This has prompted research into materials with improved resistance to UV rays, increased strength-to-weight ratios and corrosion.

- Integration with monitoring systems – one of the innovations is the way the dampers integrate with monitoring systems. Real-time cable vibration analysis and detection is possible with these technologies. This makes it possible to actively maintain and modify dampening systems.

- Better installation techniques – these developments concentrate on making the installation procedure easier. This covers the creation of specialized instruments and apparatus for effective installation.

- Design optimization – current studies aim at improving spiral vibration damper designs. The purpose of this is to increase vibration control’s efficacy. To enhance damping efficiency. This entails researching elements including the dampers’ dimensions and shape, their spacing and their attachment mechanisms.

Frequently asked questions

In ADSS cables, aeolian vibrations operate means of spiral vibration dampers. They assist in lessening the amplitude of vibrations in cables caused by wind. By doing this, you may increase the wires’ lifespan and guarantee dependable operation.

High-strength, corrosion-resistant materials, including aluminum alloy or galvanized steel, serve to make spiral vibration dampers. These materials provide lifespan and resilience in outdoor settings.

Novel materials, optimized designs, monitoring system integration, personalization and better installation techniques are some of the advancements.