A guy wire is a tensioned cable or wire that helps support and stabilize utility poles. It works where extra support is necessary to reduce lateral forces on poles. The tension in the guy wire helps to balance the forces which prevents leaning or bending. Guy wires attach to the pole or tower at one end and anchored securely to the ground or concrete at the other end. It is mainly made of steel or galvanized steel to resist rust and corrosion. The number and location of the guy wires depends on the height of the pole, weight of the power lines and wind conditions. Guy wires enhance the structural integrity of the power line system. This then ensures the stability and safety of the lines. The wires work in areas with high wind loads or long distances between structures.

Components of guy wires

A guy wire has a variety of components that work together to create a robust and stable guy wire system. Different types and designs of the guy wire consist of different components. The components vary depending on the size and weight of the power lines, wind loads and the supporting structure. The following are the key components of a guy wire.

- Guy wire– this is the main components of the system that provides the required support and stability to the utility poles.

- Anchors – these are devices used to secure the guy wire to the ground. They install underground or in concrete foundations.

- Turnbuckles – these are tensioning devices used to tension the guy wire by lengthening or shortening the guy wire.

- Thimbles – these are protective sleeves used to reinforce the guy wire at points where it makes contact with other components. They prevent abrasion and damage to the guy wire.

- Guy wire clamps – these clamps fasten and secure the guy wire to the pole or tower while allowing for adjustment and tensioning.

Types of guy wires

Different types and designs of high-performance steel strand for tower guy wires work to meet different specifications of the application. The specific type used depends on various factors. These factors include the application, required strength, environmental conditions and local regulations. Therefore, it is advisable to carefully select the suitable guy wire type to ensure integrity and safety of the overhead power lines. The following are the common types of the guy wires used in the industry.

Galvanized steel strand – this is the most common type of guy wire which consists of multiple high-strength steel wires twisted together to form a single cable. It is corrosion resistant which makes it suitable for outdoor applications.

Aluminum-clad steel – this is a composite guy wire that consists of a central steel core with an aluminum cladding. The aluminum layer provides conductivity for lightning protection while the steel core provides strength.

High-performance steel strand – this is also known as extra-high-strength strand which offers greater strength than galvanized steel strand. It is from high-strength steel alloys designed to withstand higher tension loads. It works in areas with extreme weather conditions.

Fiber optic strand – these are mainly designed to hold fiber optic cables. This allows for efficient and reliable communication infrastructure along with power transmission.

Applications of properly tensioned guy wires

Guy wires helps to increase and enhance stability and support in various applications. find use in various application areas in the industry depending on the specifications. Different types of the guy wires meet different intentions of the applications. Guy wires also ensure the integrity and safety of various structures and installations. The following are the main application areas of the guy wires.

- Overhead power lines – guy wires provide extra support and stability to utility poles. This helps them to withstand wind loads and ensure the safe and reliable transmission of electricity.

- Antenna masts – guy wires support antenna masts for applications such as radio antennas, satellite dishes and wireless communication components. This enhances signal reception and transmission capabilities of antennas.

- Flagpoles – guy wires support tall flagpoles to ensure stability and prevent swaying or leaning. Guy wires help maintain the upright position of the flagpoles in windy conditions and other environmental factors.

- Telecommunication towers – guy wires also help in the construction of tall communication towers. These include radio and TV broadcast towers and cellular communication towers.

- Wind turbines – they are also used to support tall structures that house wind turbines. This enables the efficient harnessing of wind energy.

- Construction – guy wires provide temporary or permanent support to structures during construction or repair. This helps stabilize temporary scaffolding, cranes or other structures.

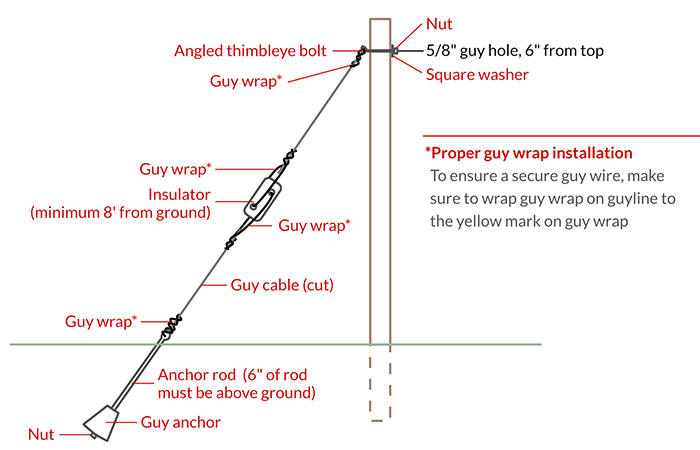

How to install and anchor guy wires for power poles

Installation process of the guy wires consists of various steps to ensure proper setup and effectiveness. The specific installation process varies depending on factors such as type of guy wire, local regulations and specific requirements of the project. Some manufacturers offer installation guidelines for their specific product. Additionally, it is advisable to consult with industry experts for guidance during the installation of guy wires. The following is a basic step by step process for guy wire installation.

- Assess the installation site to determine the suitable locations for guy wire placement. Consider factors such as terrain, soil conditions, distance between support structures and wind loads.

- Prepare the poles by inspecting their structural integrity and conduct any necessary repairs and reinforcements.

- Position the guy wire based on engineering calculations and site-specific requirements. Place the anchors at predetermined distances from the pole or tower.

- Install the anchors by burying to the ground or attaching to concrete foundations. The depth and size of the anchor will depend on the soil conditions and required load bearing capacity.

- Attach the dead-end attachment to the poles or towers using the clamps or other connectors.

- Tenson the guy wire using turnbuckles or other tensioning devices to achieve the required tension.

- Install the clamp to fasten and secure the guy wire to the poles or towers. Position and tighten them to ensure a strong grip on the guy wires.

- Place the strain insulator between the guy wire and the pole to prevent electrical conductivity for a safe system.

- Inspect the guy wire installation to ensure proper tensioning, alignment and attachment. Make any necessary adjustments to ensure the integrity and effectiveness of the system.

Selecting the best guy wire for your application

The selection process of guy wire involves considering various factors. These factors ensure the chosen guy wire is suitable for the application. it should meet the requirements and the required safety and performance standards. Therefore, it is important to consult with industry experts for guidance on the best guy wire to use for your application. This helps to ensure stability, safety and longevity of the supported structure. The following are the factors to consider when selecting the guy wires for your application.

- Conduct as cost analysis of different types of guy wires by factoring material costs, installation expenses and long-term maintenance requirements.

- Conduct a load analysis to determine the forces acting on the structure that require guy wire support. This helps determine the required strength and capacity of the guy wires.

- Select the guy wire material based on its mechanical properties. This includes tensile strength, flexibility and resistance to corrosion.

- Factors such as temperature, humidity and exposure to corrosive substances might influence the selection of the guy wire.

- Consider factors such as span distance, desired tension and safety factors to determine the engineering calculations or the guy wire.

- Ensure the guy wire selected complies with applicable safety standards, regulations and codes required for strength, material specifications and installation practices.

- Select guy wire from a reputable manufacturer and supplier to ensure quality and reliability of the guy wires.

Frequently asked questions

What is a guy wire as used on overhead power lines?

A guy wire is a tensioned cable that helps support and stabilize utility poles or transmission towers. This helps to counterbalance the horizontal forces acting on the pole or tower to prevent leaning or bending.

What are the advantages of a guy wire?

Guy wire offer several benefits to overhead power applications that promote the use of guy wires. These advantages contribute to the reliable and efficient operation of these systems. The advantages include safety, flexibility, improved resistance to environmental conditions, increased load capacity and structural stability.

What are the limitations of guy wires?

As much as they offer many advantages, guy wires also have various limitations. These limitations should help in the planning and design phases to ensure suitable use of guy wire. These limitations include construction delays and restrictions, environmental factors, interference with other structures, requires much land space, visual impacts and installation complecxity.