Chile’s Codelco is preparing a 25% cut in its indirect emissions by 2030 as part of its decarbonization plan. Codelco is the biggest copper manufacturer, but its mining contributes to pollution. Copper is a key material in solar panels, wind turbines, and energy transmission due to its electrical conductivity and durability. It also serves in electric vehicles, charging infrastructure, and battery storage solutions. This makes it a crucial component in Chile’s renewable energy transition. Codelco has various measures and initiatives to reduce emissions from copper mining. It is transitioning to renewable energy sources for its operations. This is through signed agreements with renewable energy providers to supply its mines with solar, wind, and hydropower. For instance, Codelco’s Chuquicamata and El Teniente mines are powered by renewable energy to reduce emissions. Brace crossarms reinforce the poles and transmission towers to ensure stability against strong winds and electrical loads.

Copper mines need high-voltage power lines to transport electricity from power plants to remote mining sites. Most structures use brace crossarms to distribute mechanical stress and reduce the risk of structural failures in harsh mining environments. The crossarms also reduce vibrations caused by electrical currents and external forces. Brace crossarms are crucial in Chile’s copper mining industry for power transmission stability, structural reinforcement, and safety. Using brace crossarms ensures the energy reaches mining sites efficiently to support the country’s massive copper production.

The roles of brace crossarms in Chile’s copper mining decarbonization

Brace crossarms are structural components used in the construction of transmission towers or pole line supports. They help stabilize the towers and ensure the safe and efficient distribution of electrical power. Crossarms help deliver electricity to various parts of the mine, including processing plants, equipment, and facilities. The use of brace crossarms enables the electrification of mining equipment, integration of renewable energy, and reduction in emissions. Here are the roles of brace crossarms in copper mining and decarbonization in Chile.

- Supporting electrification and mining operations—brace crossarms maintain the electrical infrastructure needed to power the equipment. They ensure the stability and reliability of power lines delivering electricity to mining sites.

- Renewable energy integration—mining operations are sourcing electricity from renewable energy projects. Brace crossarms connect renewable energy plants to mining sites and ensure stable and continuous power supply.

- Ensuring energy efficiency—efficient power distribution reduces energy losses in mining operations. Transmission towers with robust brace crossarms reduce energy waste, which contributes to energy efficiency.

- Technological advancements—brace crossarms help maintain the integrity of power lines and ensure the technologies function smoothly. This is because mining operations use advanced technologies such as automation and digitalization.

- Reducing reliance on diesel generators—brace crossarms can enhance electrical grid reliability to reduce their dependence on diesel, cutting emissions.

Codelco’s initiatives in reducing emissions from copper mining in Chile

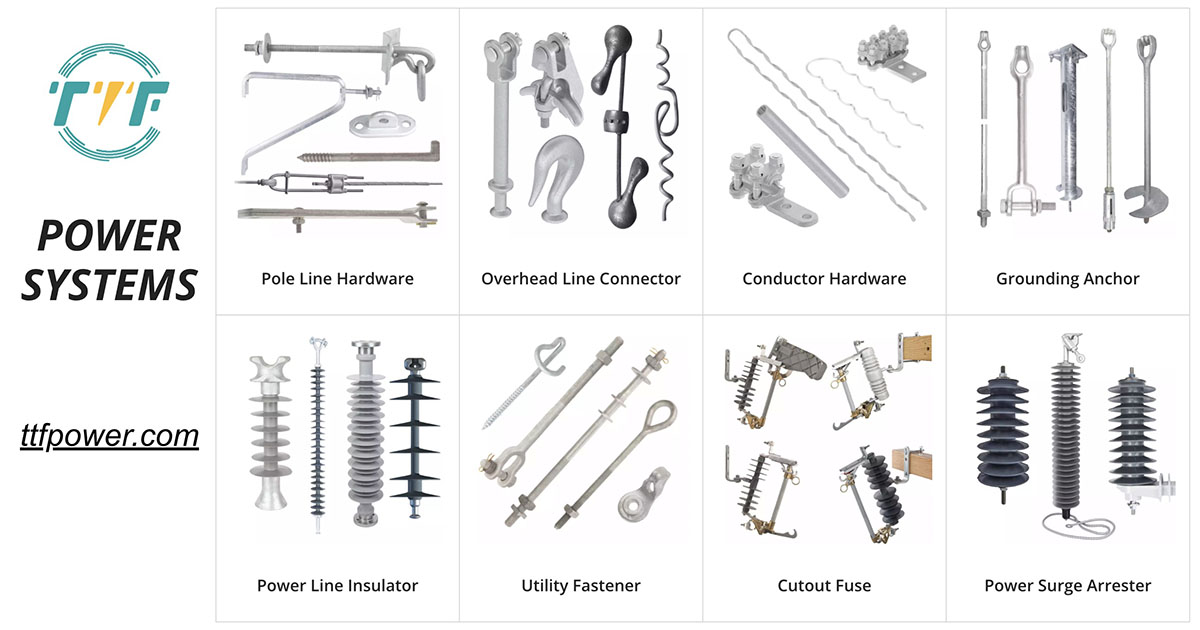

Chile’s Codelco has been implementing a range of initiatives to reduce emissions from its mining operations. These efforts are part of its broader commitment to sustainability and alignment with Chile’s national decarbonization goals. The initiatives employed will help reduce emissions and position Codelco as a leader in sustainable mining practices. TTF Power supports sustainable mining in Chile by providing high-quality power line hardware. We provide products like transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. Discussed below are the key initiatives Codelco is using to cut emissions.

- Electrification of mining equipment—Codelco is replacing diesel-powered trucks, loaders, and heavy machinery with electric alternatives. The company is also using electric equipment such as drills and load, haul, dump vehicles to reduce diesel consumption.

- Renewable energy adoption—Codelco has signed long-term agreements with renewable energy providers to supply its operations with solar, wind, and hydropower. It is also exploring the installation of solar panels at mining sites to generate clean energy locally.

- Energy efficiency improvements—Codelco is putting in place advanced technologies and process improvements to reduce energy consumption in its mining and processing operators. It is also investing in modern, energy-efficient machinery and retrofitting older equipment to improve performance and reduce energy use.

- Carbon capture and storage—the company is investigating the feasibility of carbon capture and storage technologies to mitigate emissions from its operations. This technology could reduce emissions from processing plants and other fixed sources.

- Digitalization and automation—Codelco is using digital technologies such as IoT, AI, and automation to optimize operations. Using autonomous trucks and drills improves efficiency and reduces fuel consumption, which contributes to lower emissions.