Lithium prices have experienced volatility over the years, which influences fluctuations in electric vehicle sales. Lithium prices dropped over 80%, which is accredited to global oversupply and a slowing down in EV adoption rates. Argentina, Bolivia, and Chile are the major players in lithium production. They contribute to the sustainable development of the EV industry. Mining corporations are making strategic investments in the lithium sector. For instance, Rio Tinto has announced a $2.5 billion investment in Argentina’s lithium project. Lithium production provides economic opportunities for South American countries. It can generate revenue, create jobs, and stimulate economic growth in the region. Lithium extraction can have environmental impacts, including water scarcity and pollution. A cutout fuse is essential in the electrical infrastructure supporting lithium extraction operations.

Cutout fuses help supply electricity to the mining sites, processing plants, and related facilities. They also help protect the equipment within the extraction and processing facilities. Cutout fuses help ensure the safe and reliable operation of the electrical systems supporting lithium mining. Cutout fuses enhance the safety of workers by reducing the risk of electrical accidents. The fuses enable the implementation of sustainable extraction practices by ensuring lithium production for electric vehicles remains environmentally viable. This helps support the region’s growing electric vehicle industry.

Lithium extraction process reducing prices in South America

The use of innovative lithium extraction methods prioritizes sustainability and develops recycling infrastructure. These methods can help ensure a sustainable and affordable supply of lithium for the global EV market. Efficient extraction methods can reduce production costs for lithium, which makes EV batteries more affordable. The extraction techniques can increase lithium supply, which stabilizes lithium prices. The following are the lithium extraction processes utilized in South America to reduce prices.

- Direct lithium extraction—this technology extracts lithium from brine more efficiently than traditional evaporation ponds.

- Improved brine evaporation techniques—innovations in evaporation technology help reduce energy consumption and speed up the extraction process.

- Recycling and reuse—recycling lithium from spent EV batteries can reduce the demand for primary lithium extraction. The technology creates a circular economy for lithium and reduces reliance on primary extraction.

- Sustainable mining practices—these aim to reduce environmental impact through responsible water management, reducing waste, and implementing renewable energy sources can enhance lithium sustainability.

The role of a cutout fuse in lithium extraction for electric vehicles

A cutout fuse ensures the safety and integrity of electrical systems used in lithium extraction processes. It protects electrical systems and maintains operational continuity to position the region in the global EV battery supply. The following are the roles of cutout fuses in lithium for electric vehicles.

- Equipment protection—cutout fuse—provides a critical layer of protection by isolating electrical faults. They protect machinery like pumps, crushers, and conveyor systems.

- Ensuring process continuity—cutout fuses reduce downtime by isolating faults to specific components. This helps prevent widespread power outages. Lithium brine extraction operations are mostly in remote areas such as Argentina’s salt flats or Chile’s Atacama Desert.

- Safety in high-voltage applications—lithium extraction facilities use high-voltage systems to operate large-scale processing equipment. Cutout fuses ensure worker and system safety by disconnecting faulty electrical lines.

- Protection in renewable-powered operations—cutout fuses help manage the changes and faults in the renewable inputs. This is to ensure stable and reliable operation of equipment. Most South American lithium facilities integrate renewable energy sources like solar and wind into the power systems.

- Reliability in harsh environments—a cutout fuse operates reliably in environments with high temperatures, dust, and corrosive conditions.

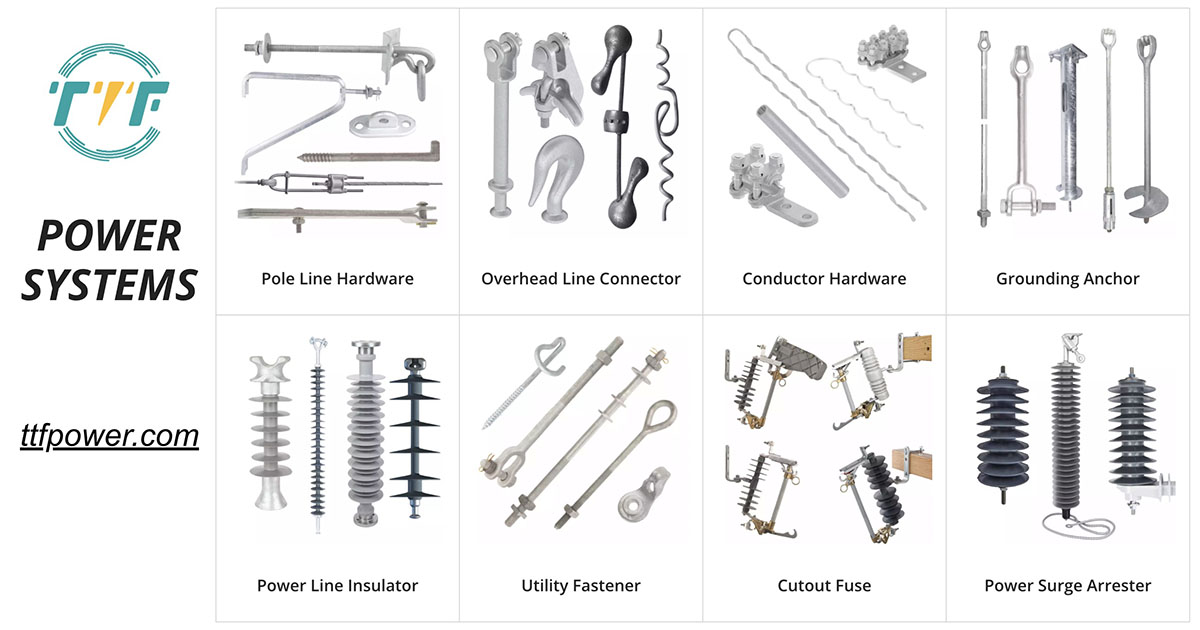

Opportunities for lithium in the electric vehicle industry

South America has the potential to become a major player in the global electric vehicle industry. This is by leveraging its abundant lithium resources, developing its value chain, and prioritizing sustainable and responsible mining practices. The presence of lithium reserves in the region provides economic growth, value chain development, technological innovation, and regional collaboration between countries. This can enhance regional competitiveness, attract investment, and promote sustainable development. Lithium extraction processes should enhance sustainable mining processes and mitigate environmental impacts. Chile, Argentina, and Bolivia hold over 50% of the world’s lithium reserves. Addressing these challenges and developing its resources can solidify its role as a global powerhouse in the green mobility revolution. TTF is a world-class global provider of high quality overhead line hardware, transmission hardware, distribution hardware, conductors, insulators, cutout switches, anchoring and grounding products. These products aid in the construction of lithium mining infrastructure.