A shackle insulator is an insulator used to support and insulate conductors from the supporting structures. Shackle insulators ensure the safe and efficient operation of overhead power lines. It is also known as a suspension insulator or a string insulator. It is from materials such as porcelain, composite or glass. Shackle insulators used depend on the line voltage, environmental conditions and the mechanical stresses. Shackle insulators ensure the reliable electrical transmission. This includes even the high-pollution in the diverse climates of Southeast Asia. Common types include porcelain, composite, glass, bell and long rod shackle insulators. They find use in applications such as suspension of conductors, electrical insulation, voltage levels, telecommunication and transmission lines.

Key features of the shackle insulator

There are various features of the shackle insulators that make them suitable for use in various applications. The features help to provide electrical insulation and mechanical support. This also helps them to maintain the integrity and reliability of the power grid. The following are the key features of the shackle insulator.

- Insulating material – they are from materials such as composite, glass or porcelain. These materials help them resist flow of current to the unwanted areas.

- Design configuration – the insulators are in various deigns such as discs, bells or flat plates. The design chosen depends on factors like voltage level and mechanical loads.

- Electrical insulation – they provide electrical insulation between the energized conductor and the grounded supporting structure.

- Mechanical strength – they are able to withstand mechanical stresses and loads. This helps them support the weight of the conductors and resist forces from wind, ice and line movement.

- Corrosion resistance – the insulators are corrosion resistant to ensure the long-term performance.

- Ease of installation – the stay insulators are easy and simple to install on transmission towers.

- Safety – the insulators contribute to the safety and reliability of electrical power systems. This is by preventing electrical faults on the systems. This is to ensure the continuity of the power transmission and distribution.

Selection and installation of shackle insulators

The selection of the shackle insulators involves considering various factors. These factors include voltage level, mechanical load capacity, creepage distance, material, line configuration, weight and size. The installation process should ensure the safe and reliable operation of the electrical system. Additionally, it is advisable to consult with the experts and engineers. They offer guidance on the installation and selection of the shackle insulators. The following is a basic installation process of shackle insulator.

- Safety precautions – observe all the necessary safety protocols during installation. This includes the use of personal protective equipment and adherence to safety guidelines.

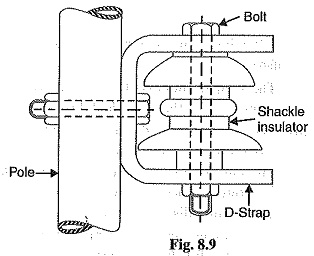

- Equipment and tools – gather all the necessary equipment and tools. These includes insulators, shackles, conductor clamps, bolts and wrenches.

- Site inspection – conduct a thorough inspection of the installation site. Ensure there are no visible defects.

- Insulator positioning – identify the locations on the conductor where the shackle insulators will attach. This should base on the design and configuration of the overhead line.

- Gather insulators – collect the insulators by attaching them to the shackles. This is by following the manufacturer’s instructions.

- Conductor attachment – attach the conductor to the desired location. This is by opening the shackle and securing it around the conductor.

- Fasteners – use the appropriate bolts and nuts to secure the insulator pins in place and tighten them to the recommended torque levels.

- Creepage distance – ensure the distance along the surface of the insulator between the two energized parts meet the specifications.

- Alignment – ensure the shackle insulator aligns properly with the conductor and the supporting structure.

- Inspection – conduct a final inspection to check for any defects or issues that may affect their performance.

- Documentation – maintain detailed records of the installation. This includes insulator type, serial numbers and installation date.

Maintenance and inspection of shackle insulator in Southeast Asia

Shackle insulators require regular maintenance and inspection to ensure the continued reliability and safety. It also helps identify and address issues before they lead to electrical faults or insulator failure. Maintenance and inspection also maintains the integrity and reliability of transmission lines. The following is a basic guide for the maintenance and inspection of shackle insulators in Southeast Asia.

- Establish a regular inspection schedule based on industry standards and manufacturer recommendations.

- Conduct visual inspections to look for signs of damage, cracks or surface contamination.

- Measure and verify the creepage distance along the surface of the insulators. Also, ensure the creepage distance complies with the design and safety standards.

- Assess the level of contamination on the insulators and clean where necessary.

- Check the metal components for corrosion which may weaken the mechanical integrity of the insulator attachment.

- Check the alignment of the insulators with the conductor and supporting structure.

- Assess the tension of the conductor to ensure it is within the recommended range.

- Replace any damaged, cracked or components with corrosion with new components.

- Keep detailed records of all inspections including the condition of insulators, date of inspection and any maintenance or replacements performed.

Comparative analysis in Southeast Asia

A comparative analysis involves assessing and contrasting different types of shackle insulators. This includes checking on material, design, performance characteristics and suitability for specific applications. The choice of the shackle insulator also depends on specific application requirements, environmental conditions, mechanical loads and budget. The following are the common factors to include in a comparative analysis for shackle insulators.

- Material – the main materials for a shackle insulator includes porcelain, glass or composite. These materials have good electrical insulation properties, resistance to corrosion and exposure to UV radiation.

- Mechanical strength – depending on the material, the insulators have high mechanical strength. This makes them less susceptible to damage.

- Weight – the shackle insulators reduce the overall weight and stress on supporting structures.

- Pollution resistance – shackle insulators are popular for their ability to shed contaminants and maintain electrical performance. They offer pollution-resistance in highly polluted environments.

- Environmental resistance – the shackle insulators should be resistant to UV radiation, weathering and environmental factors.

- Costs – the insulators are cost effective depending on the material but may have higher maintenance costs.

- Application range – the insulators find use in various voltage levels such as high, medium and low voltages.

Certifications and standards of shackle insulator in Southeast Asia

There are various standards and regulations that the shackle insulator must comply to in Southeast Asia. Many countries in the region adopt international standards for electrical equipment and insulators. Additionally, the manufacturers and suppliers should work closely with the local regulatory authorities. This is to ensure their products meet the relevant standards and certifications requirements for the market. The following are the common certifications and standards in Southeast Asia.

- IEC standards – this are standards for electrical equipment including shackle insulators.

- ANSI standards – these are standards for insulators used in transmission and distribution systems.

- ASTM international – this publishes standards for various materials including insulating materials used in insulators.

- ISO standards – these are standards related to electrical insulating materials and testing methods.

- IECEE CB scheme – this is an international system for the mutual acceptance of test reports and certificates for electrical and electronic products.

- Local regulatory standards – each country has their own national or local standards and certification requirements for electrical equipment.

Regional market for shackle insulators in Southeast Asia

There are various factors that influence the regional market for shackle insulators in Southeast Asia. There are various trends that shape the market for the insulators despite the market dynamics and challenges. Additionally, the demand for reliable electrical transmission and distribution systems supports the market’s growth. This in turn makes it an attractive sector for manufacturers and suppliers of shackle insulators. The following are the common factors that shape the regional market for shackle insulators in Southeast Asia.

- Rapid urbanization – increased electricity consumption in urban areas leads to rapid urbanization. Shackle insulators work in such areas that need power transmission to the growing cities.

- Renewable energy growth – increased investment in sources such as wind and solar require the use of shackle insulators to support transmission lines.

- Infrastructure development – investments in infrastructure development includes the expansion and modernization of electrical grids. This development requires the installation of new shackle insulators on the transmission lines.

- High voltage transmission – increased need for high voltage transmission lines demands the increased use of shackle insulators.

- Local manufacturing – local manufacturing of shackle insulators influences the market dynamics and supply chain.

- Competition – competition between local and international manufacturers of electrical insulators also affect the demand in the market.

Frequently asked questions

What is a shackle insulator?

This is an electrical component used to support conductors and provide electrical insulation. They are commonly used in Southeast Asia’s power grid infrastructure. This is to ensure reliable electricity distribution from one point to another.

How to maintain shackle insulators in areas with high pollution or humidity?

Shackle insulators require regular visual inspections, cleaning and monitoring pollution levels in such conditions.

What is the advantage of using shackle insulators in Southeast Asia?

Shackle insulators are light weight, pollution-resistant and durable in tropical climates of Southeast Asia. They are less prone to cracking and offer long service life which makes them suitable for the diverse climates of Southeast Asia.